Anti-interlocking device and its distribution cabinet

A technology of interlocking device and mounting frame, which is applied in the substation/power distribution device shell, air switch parts, etc., and can solve the problems of inoperability, rotation and operation of the grounding switch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

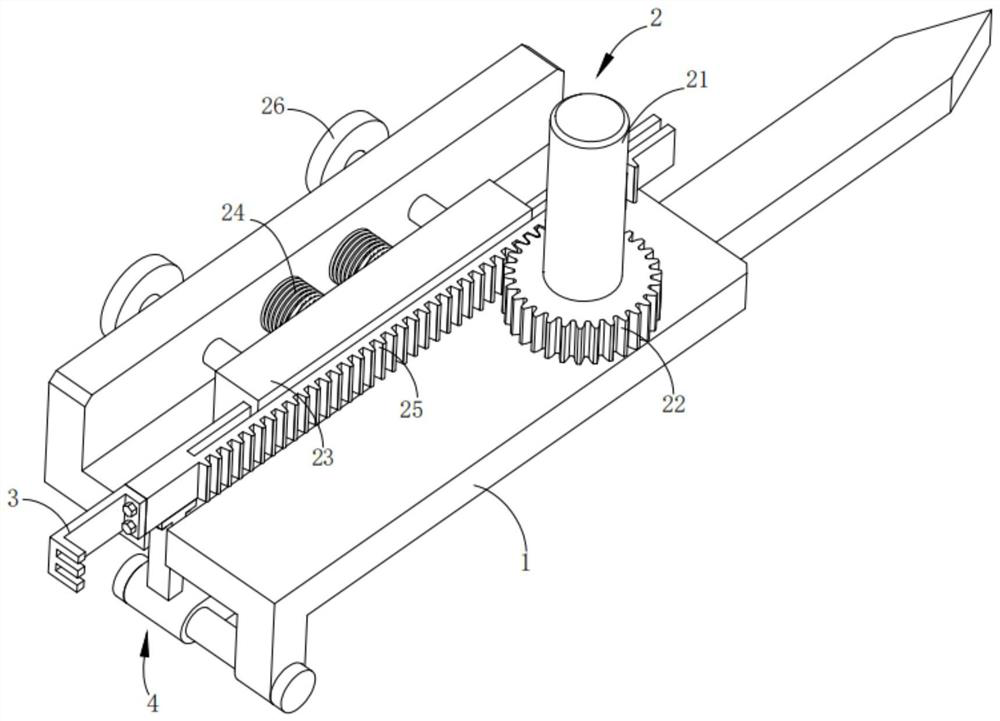

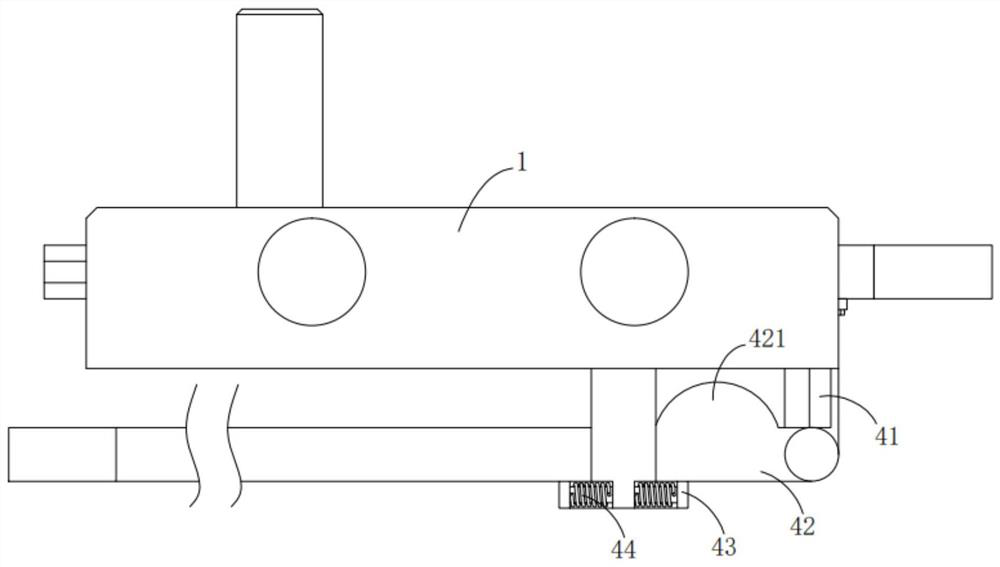

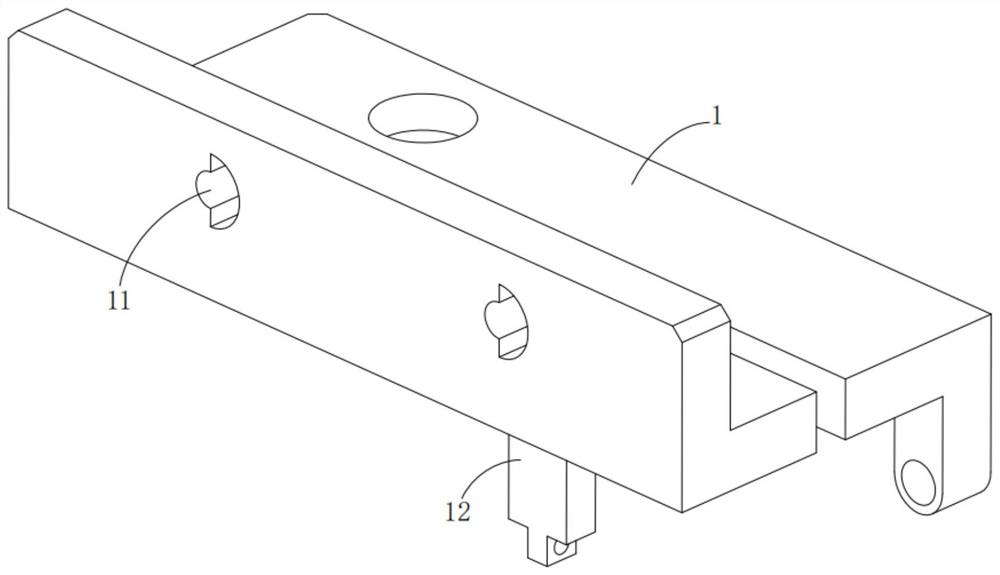

[0025] see Figure 1 to Figure 4 , the present invention provides a technical solution:

[0026] An anti-interlocking device, including a support frame 1, a driving mechanism 2, a switch knife connecting frame 3 and a grounding mechanism 4, wherein:

[0027] The supporting frame 1 is provided with a semicircular mounting hole 11 and a mounting frame 12 is provided at the bottom thereof, the driving mechanism 2 includes a rotating shaft 21, a gear 22, a linear guide rail 23, a spring 24, a rack 25 and a support rod 26, and the rotating shaft 21 passes through the bearing Installed on the support frame 1, the end of which is sleeved with a gear 22, and the two ends of the linear guide rail 23 are rotatably installed with a support rod 26, wherein the support rod 26 runs through the support frame 1 and forms a moving pair with the support frame 1, wherein The support rod 26 is provided with a semicircular catch 261, and the semicircular catch 261 on the support rod 26 fits in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com