Folding overhaul platform for high-current line of arc furnace

A maintenance platform and high current technology, applied in the field of metallurgy and iron and steel, can solve problems such as smelting production interruption, achieve the effect of solving smelting production interruption, heat generation and vibration, and improving maintenance work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

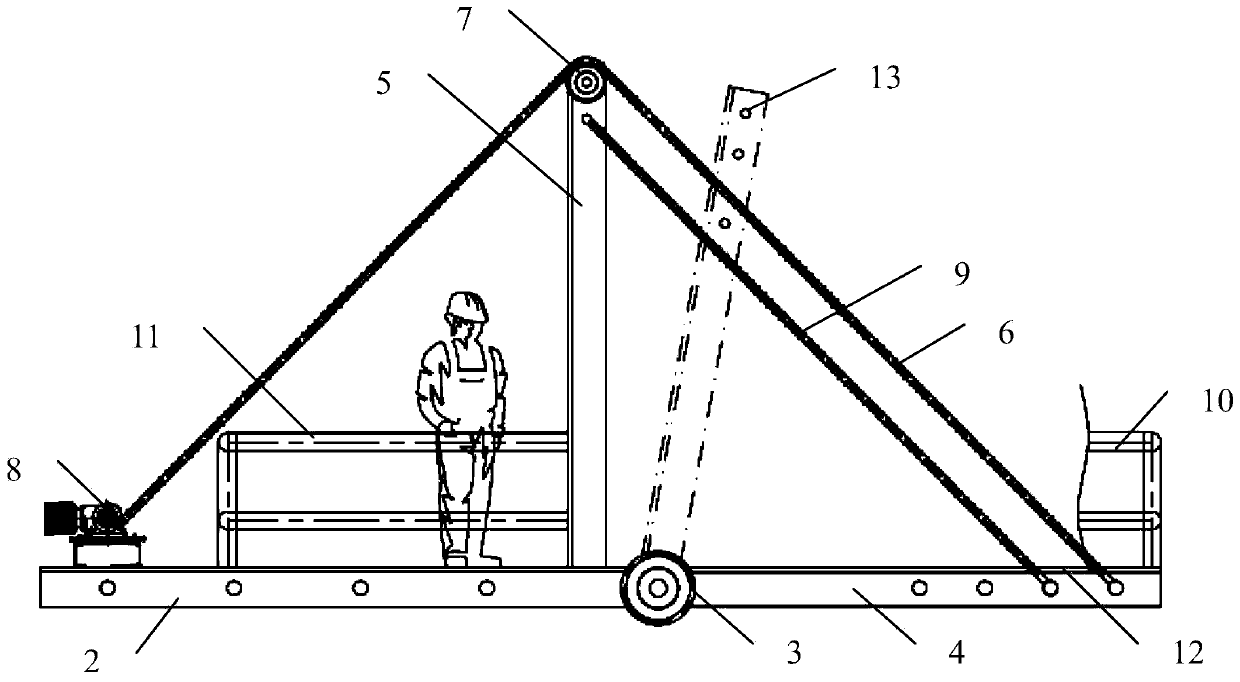

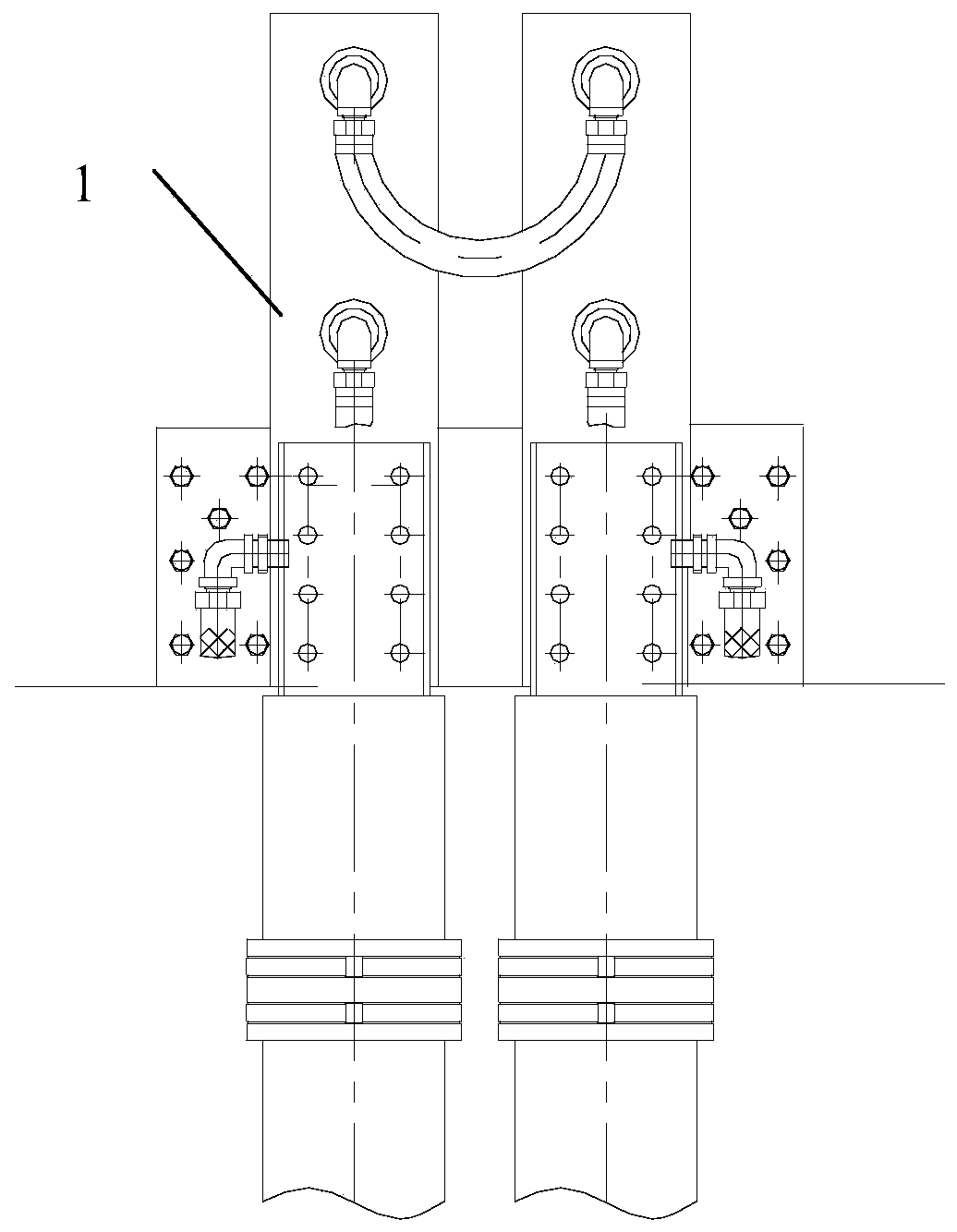

[0033] Example: see Figure 1 ~ Figure 2 , a foldable maintenance platform for high-current lines of electric arc furnaces, including fixed-section maintenance corridors 2 and folding platforms 4 arranged on both sides of high-current power supply lines 1; the upper front end of the fixed-section maintenance corridor 2 is fixedly connected There is a support column 5, and the top of the support column 5 is provided with a guide wheel 7, the guide wheel 7 is sleeved on the rotating shaft and fixedly connected with it, and the two ends of the rotating shaft are connected to the support column 5 in rotation; Movable bearing 3; the rear end of the folding platform 4 is rotatably connected to the front end of the maintenance corridor 2 of the fixed section through the movable bearing 3, and the other end is fixed on the support column 5 by a rope, the rope is a flexible steel strand 9, and the rope is symmetrically arranged on the folding platform. On both sides of the platform 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com