Tunnel furnace electrical control system and method thereof

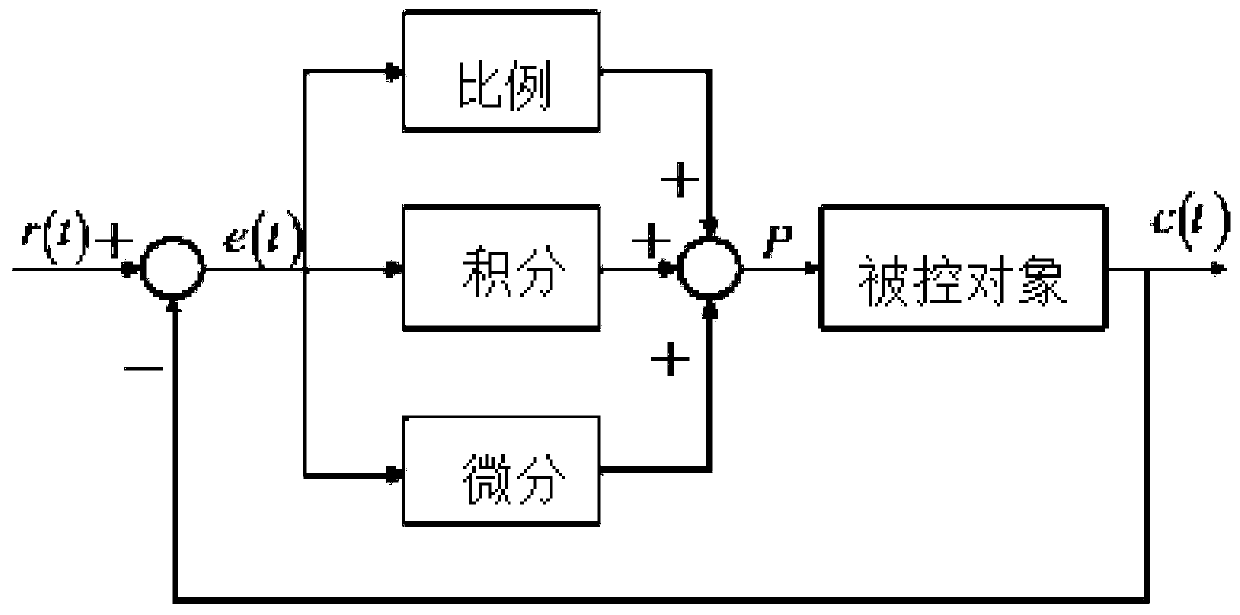

A technology of electrical control system and control method, which is applied to the air treatment device of the oven, food oven, baking, etc., and can solve the problems such as the short service life of the tunnel oven, the easy damage of the conveyor belt, and the untimely cleaning of the tunnel oven. Achieve satisfactory accuracy and temperature performance, improve communication efficiency, and overcome interference and uncertain factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

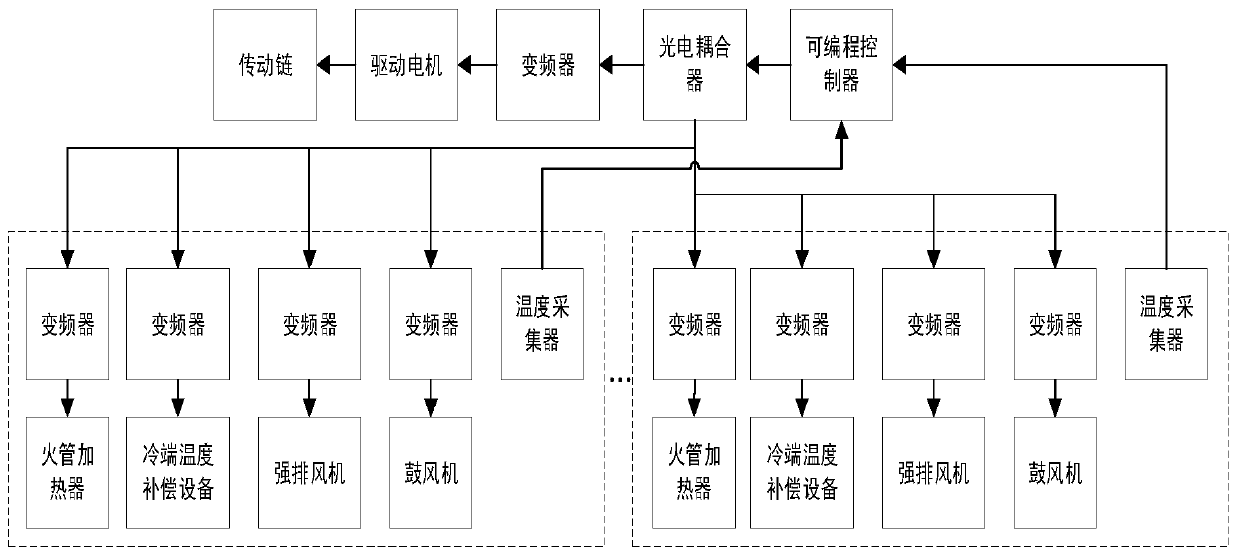

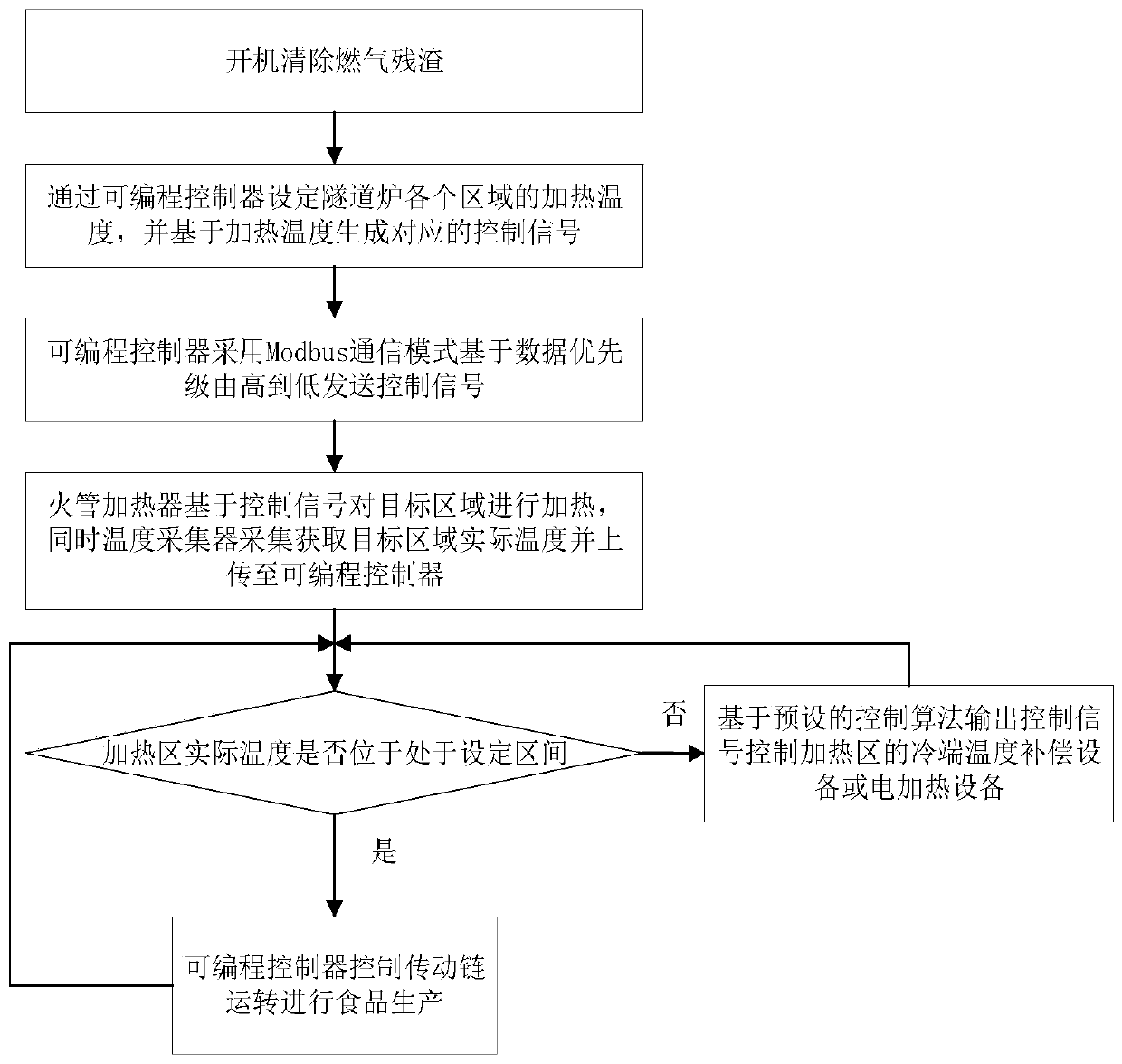

[0030] Such as Figure 1-3 As shown in one, the present invention discloses a tunnel furnace electric control system, which includes a programmable controller and a transmission chain, the transmission chain is driven by a drive motor, the programmable controller is electrically connected to the drive motor, and the tunnel furnace has multiple heating areas , each heating area is equipped with an independent fire tube heater, cold end temperature compensation equipment, temperature collector, strong exhaust fan and blower, the temperature collector collects the current temperature of the area and feeds it back to the programmable controller, and the programmable controller respectively Output control signals to the fire tube heater, cold end temperature compensation equipment, forced exhaust fan and blower, and control the fire tube heater, forced exhaust fan, cold end temperature compensation equipment or blower to work.

[0031] Specifically, the tunnel furnace is divided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com