Automatic end point quantification device and method for steam distillation

A quantitative device and end-point technology, which is applied in the field of automatic control devices for steam distillation apparatuses, can solve the problems of increasing the operator’s repeated labor and calculation times, unfavorable saving of electric energy, and damage to equipment by fractions, so as to reduce repetitive and tedious work and avoid fractions The effect of reducing hidden dangers of spillage and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

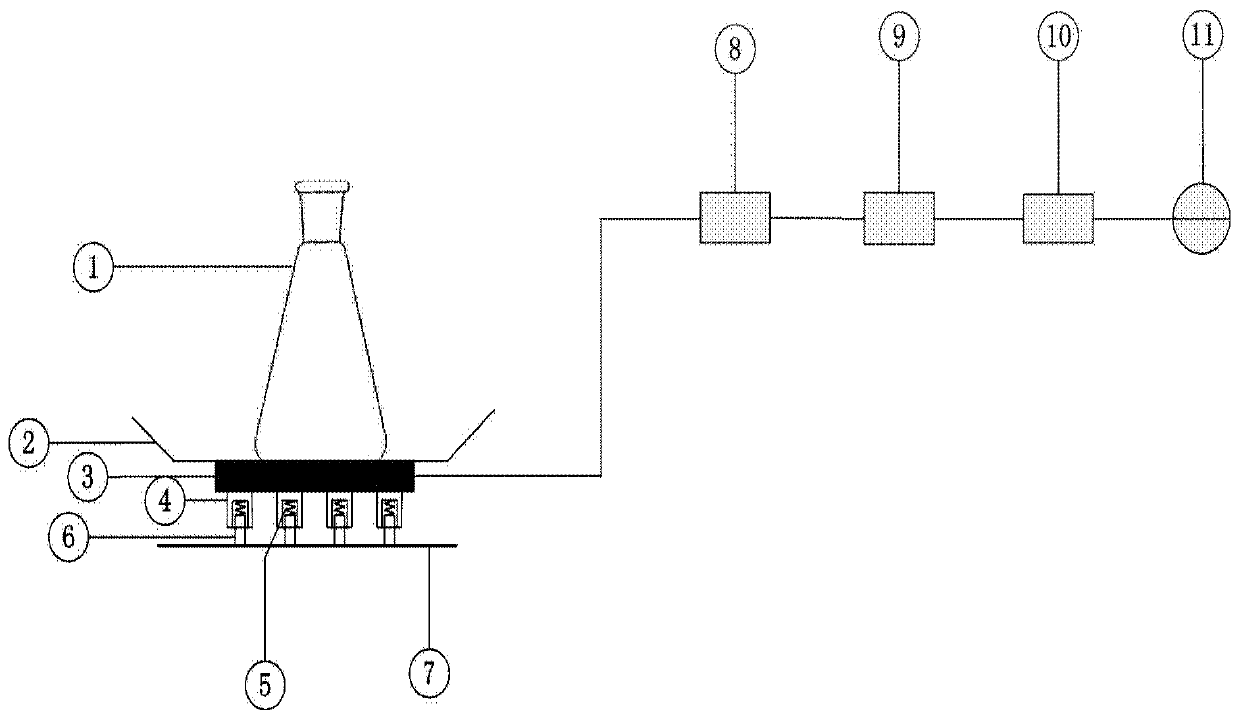

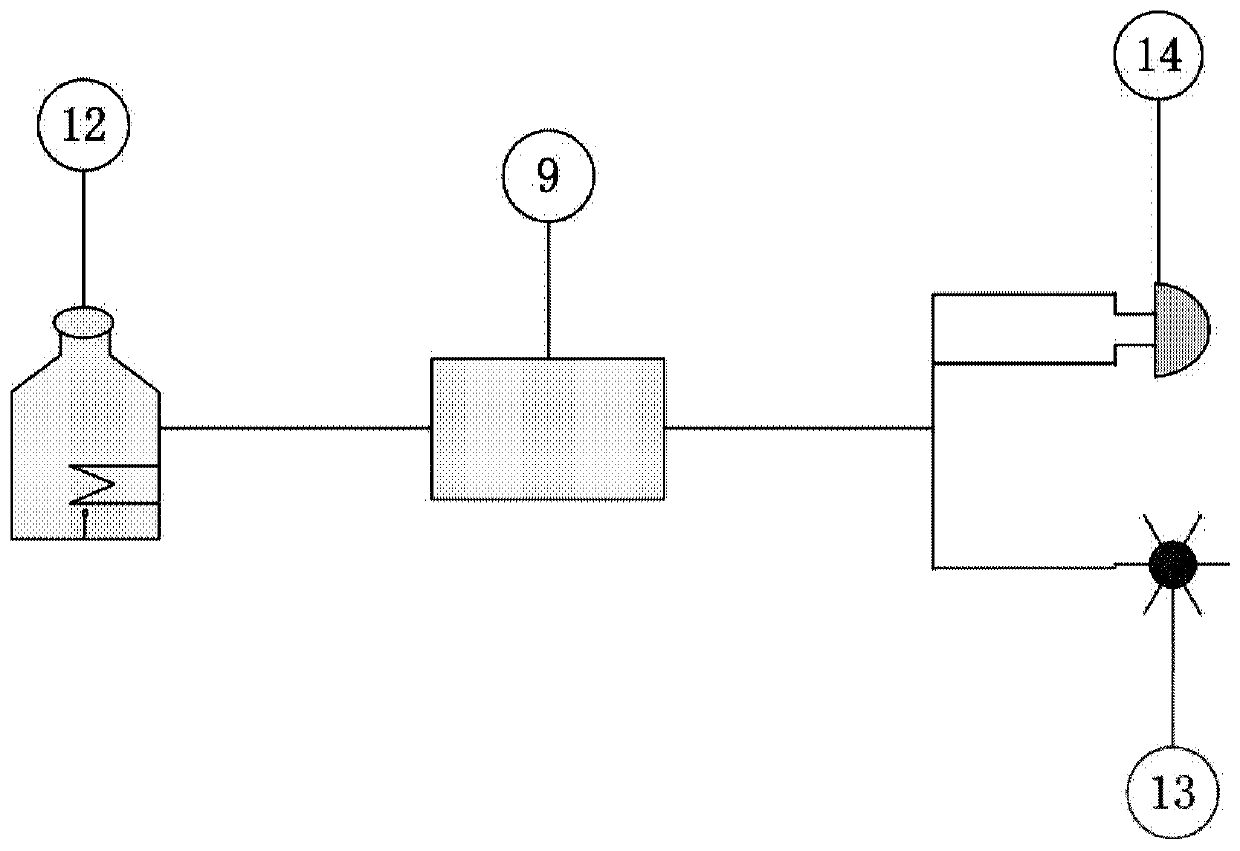

[0027] A distillation automatic endpoint quantitative device, comprising:

[0028] The base is provided with a position for placing the fraction receiving bottle;

[0029] a quantitative unit for monitoring the amount of fractions in the fraction receiving flask placed on the base; and

[0030] The control unit can generate a signal for controlling the on-off of the distillation circuit for generating fractions according to the signal output by the quantification unit.

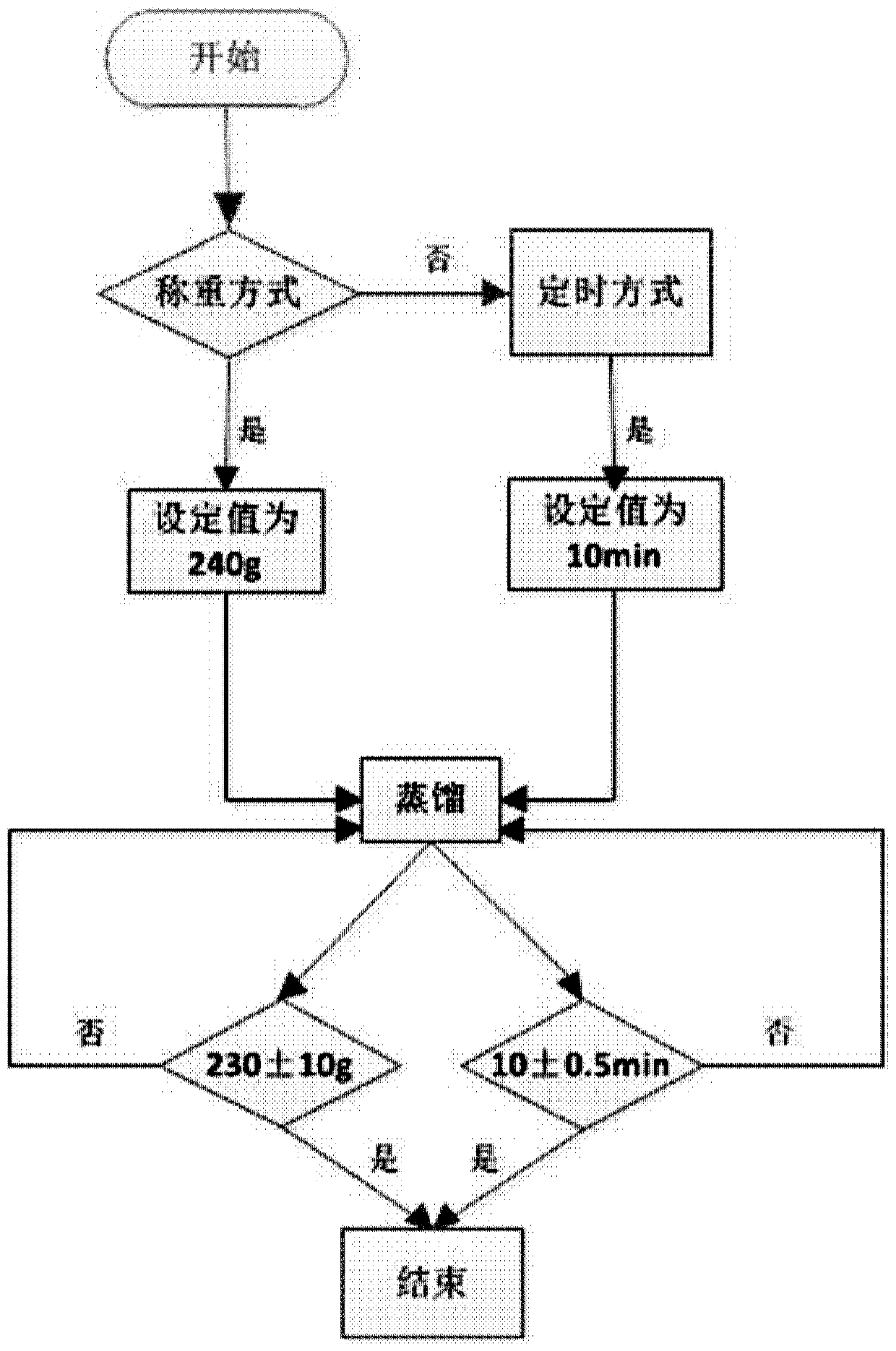

[0031] Wherein, the quantitative unit includes a pressure-sensitive bridge for monitoring the weight of the fraction, and the pressure-sensitive bridge is arranged on the base; and /

[0032] The dosing unit includes a timing component for timing the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com