Regulating device for preparing high-resolution alpha radiation source by magnetohydrodynamic electrodeposition

A technology of magnetohydrodynamics and electrodeposition, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problem of high probability of operator exposure to radioactivity, low energy resolution, poor accuracy and repeatability of deposition results, etc. problems, to achieve the effect of improving deposition efficiency and energy resolution of the source, improving experimental accuracy and deposition effect, and good deposition efficiency and energy resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

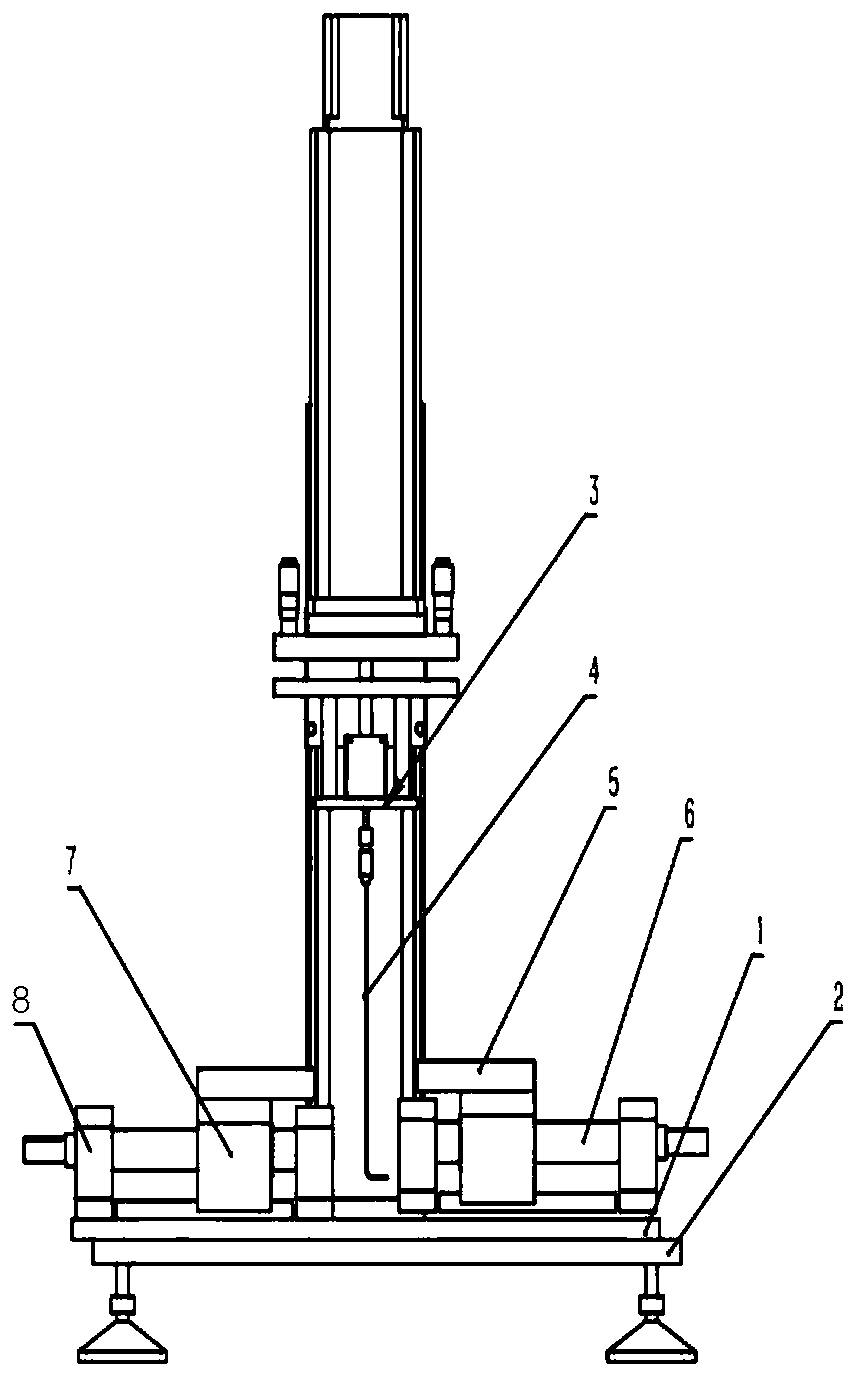

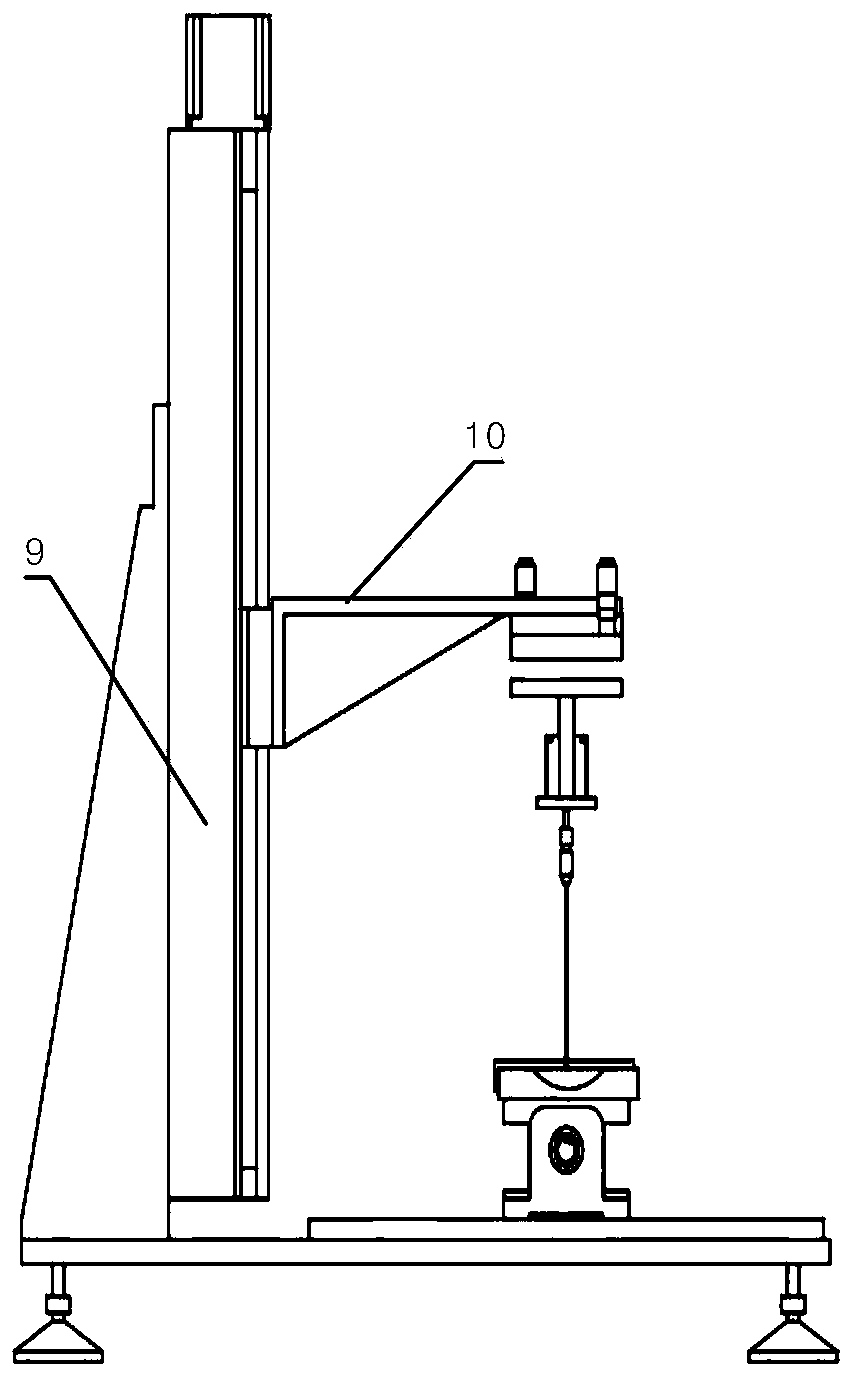

[0023] The control device for preparing an α-radiation source by the MHD electrodeposition method provided in this embodiment includes a high-precision two-dimensional positioning bracket and a permanent magnet control table. Its structure see figure 1 , figure 2 , the permanent magnet control table includes a base 1, the base 1 is provided with a round hole for fixing the deposition tank, and a magnet fixing plate 5 for fixing the permanent magnet and a magnet fixing plate 5 for adjusting the position of the permanent magnet are arranged symmetrically on both sides of the round hole. Displacement transmission. The displacement transmission device includes a bearing seat 8, a leading screw 6 and a slide block 7, the leading screw 6 is arranged on the bearing seat 8, the slide block 7 is threaded with the leading screw 6, and the magnet fixing plate 5 is fixed on the slide block 7. The high-precision two-dimensional positioning support includes a base plate 2 and a vertical ...

Embodiment 2

[0028] The device structure of this embodiment is the same as that of Embodiment 1. The difference from Embodiment 1 is that the distance between the platinum anode and the cathode deposition source sheet is adjusted to 7 mm; the rotational speed of the electrode during the electrodeposition process is 50 r / min. Apply two permanent magnets symmetrically on both sides of the cathode deposition source sheet, the magnetic flux density is 0.7T, and the distance between the center of the deposition source sheet and the center of the axial end face of the permanent magnet on each side is 14mm.

Embodiment 3

[0030] The device structure of this embodiment is the same as that of Embodiment 1. The difference from Embodiment 1 is that the distance between the platinum electrode and the cathode deposition source sheet is adjusted to 9 mm; the rotation speed of the platinum electrode during the electrodeposition process is 40 r / min. A permanent magnet is applied on one side, the magnetic flux density of the permanent magnet is 0.7T, and the distance between the center of the deposition source sheet and the center of the axial end face of the permanent magnet is 18mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com