Robot group system

A robot swarm and robot technology, applied in the direction of manipulators, manufacturing tools, etc., can solve problems such as complex road conditions, difficulty in applying rust removal projects for operating robots, and inability for operating robots to move, so as to avoid human installation errors, prevent accidents, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

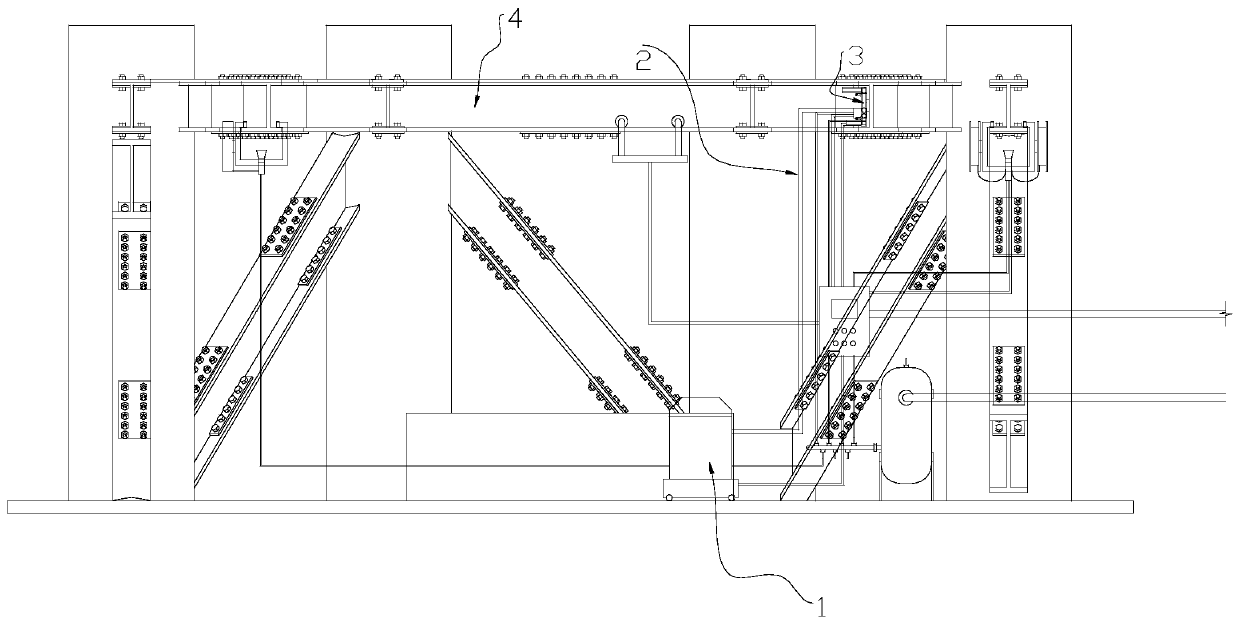

[0016] Such as figure 1 As shown, the robot group system includes a handling robot, track 4, and various operating robots. The operating robots include rust removal robots, spraying robots (galvanizing robots and aluminum spraying robots), and painting robots. The structure to be derusted includes a placement station and several construction stations, and the transport robot transports the track 4 to the placement station, so that the rail 4 passes through all the construction stations, and then the operating robot (free according to the needs of the process) Combination) is put into track 4, and work robot is installed on several moving parts 3 respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com