Method for additively manufacturing at least one three-dimensional object

A three-dimensional object, additive technology, used in machining, additive manufacturing, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

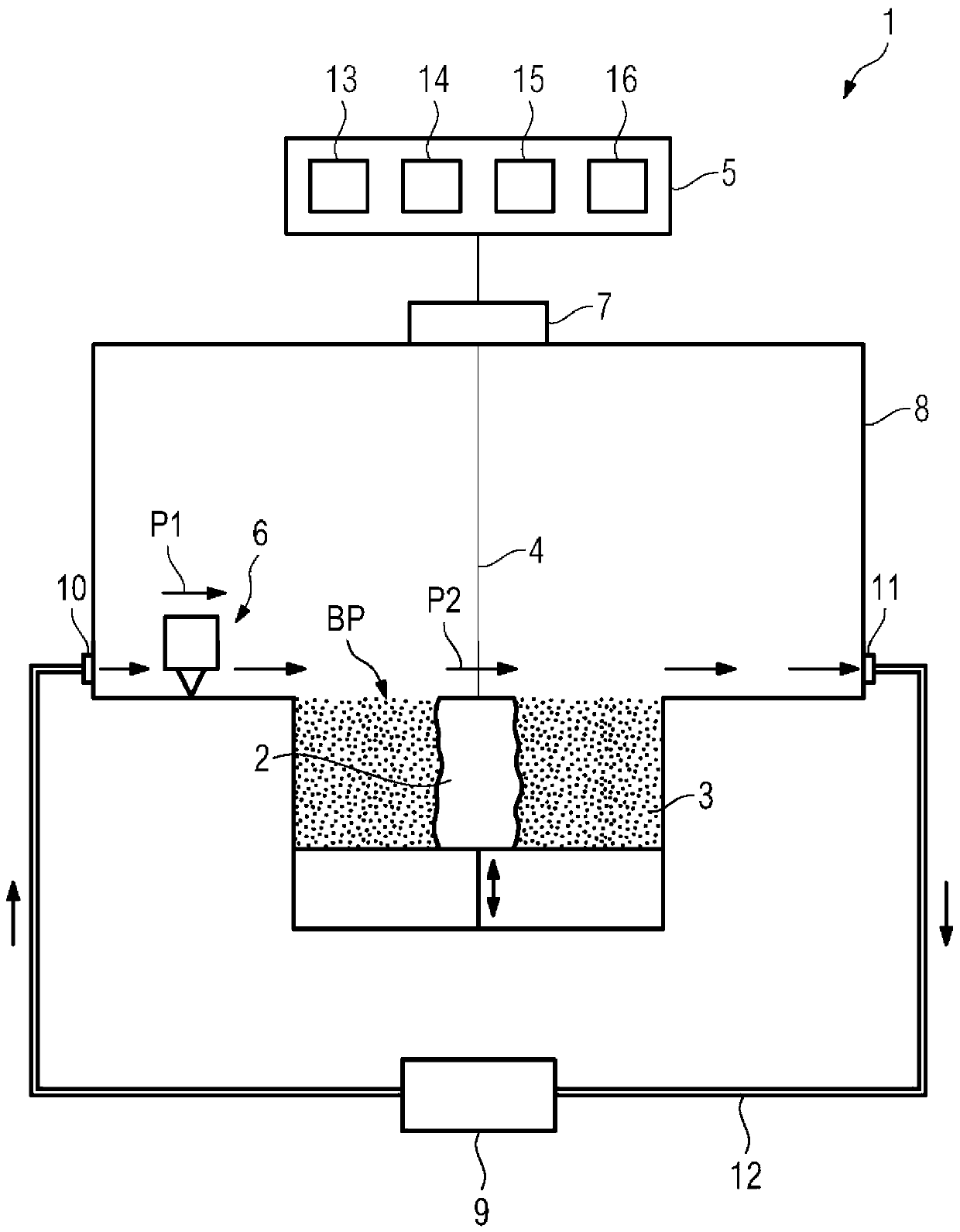

[0057] figure 1 Illustrated according to an exemplary embodiment for layer-by-layer selective irradiation and subsequent curing of layers of powdered construction material 3 curable by means of at least one energy beam 4 , for example metal powder A schematic diagram of an exemplary embodiment of a device 1 for the additive manufacturing of three-dimensional objects 2 , for example technical structural parts. The energy beam 4 can be, for example, an electron beam or a laser beam. The device 1 can thus be embodied as, for example, a selective electron beam melting device or a selective laser melting device.

[0058] The device 1 comprises a plurality of functional and / or structural units operable during and during its operation. Each functional and / or structural unit may comprise a plurality of functional and / or structural subunits. The functional and / or structural units and the operation of the device 1 are respectively controlled by a (central) control unit 5 .

[0059] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap