Label film with high transparency and high gloss, preparation method thereof and label

A high-gloss, transparent technology, applied in the field of label films, can solve the problems of limited development and application, high cost, and complicated preparation methods, and achieve the effects of strong process feasibility, excellent appearance performance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

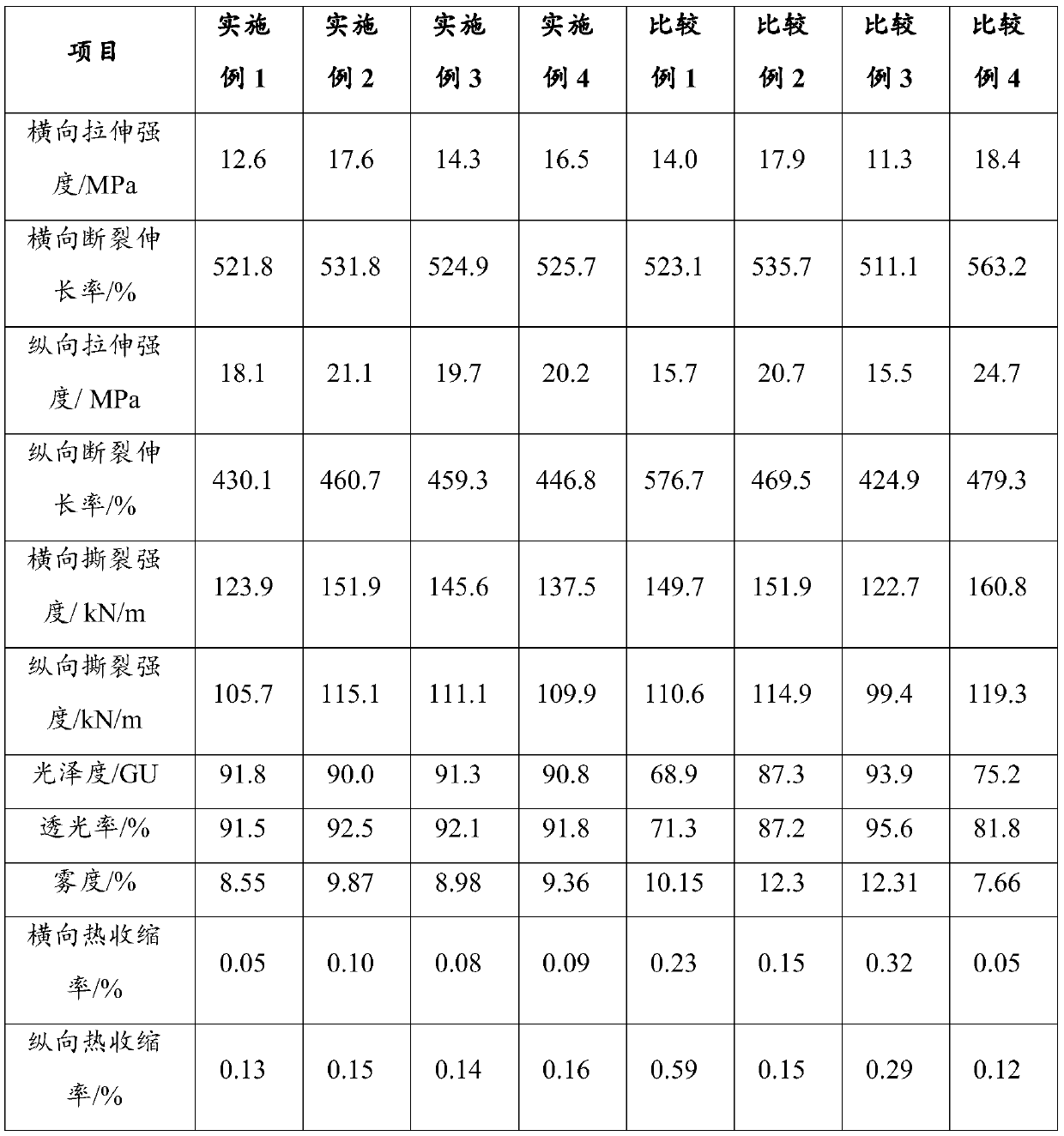

Examples

Embodiment 1

[0029] Prepare ingredients:

[0030] Take 58kg of HDPE, 26.2kg of LDPE, and 15.8kg of mLLDPE after dedusting. Among them, under the condition of 2.16kg pressure and 190°C, the melt index of HDPE is 23g / 10min, the melt index of LDPE is 8g / 10min, and the melt index of mLLDPE is 7g / 10min. 10min; the density of HDPE is 0.945g / cm 3 , the density of LDPE is 0.95g / cm 3 .

[0031] Mix according to the proportion and add to the feeding hopper, and melt and plasticize through a single-screw extruder to obtain a flowable resin. The temperature gradient for melting and plasticizing is set at 185°C-205°C-215°C, and the die head temperature is set at 215°C; then A high-brightness mirror steel roller and a finely frosted rubber roller with a surface thickness of 1500 meshes are set through parallel pressure, cooled and shaped at 18°C; then edge trimming and corona treatment are performed, and the power of corona treatment is 600W , the extrusion speed is 35m / min; the final winding is to o...

Embodiment 2

[0034] Take 60kg of HDPE, 29.5kg of LDPE, and 10.5kg of mLLDPE after dedusting. Among them, under the conditions of 2.16kg pressure and 190°C, the melt index of HDPE is 20g / 10min, the melt index of LDPE is 8g / 10min, and the melt index of mLLDPE is 8g / 10min. 10min; the density of HDPE is 0.945g / cm 3 , the density of LDPE is 0.95g / cm 3 .

[0035] Mix according to the proportion and add to the feed hopper, melt and plasticize through a single-screw extruder to obtain a flowable resin, the temperature gradient of melting and plasticization is set at 185°C-205°C-220°C, and the die head temperature is set at 220°C; then A high-brightness mirror-finished steel roller and a finely ground rubber roller with a surface thickness of 1500 meshes are set through parallel pressure, cooled and shaped at 22°C; then edge trimming and corona treatment are performed, and the power of corona treatment is 600W , the extrusion speed is 35m / min; the final winding is to obtain a label film with a th...

Embodiment 3

[0038] Take 50kg of HDPE, 40kg of LDPE, and 10kg of mLLDPE after dedusting. Among them, under the condition of 2.16kg pressure and 190°C, the melting index of HDPE is 30g / 10min, the melting index of LDPE is 5g / 10min, and the melting index of mLLDPE is 10g / 10min; The density is 0.94g / cm 3 , the density of LDPE is 0.94g / cm 3 .

[0039] Mix according to the proportion and add to the feed hopper, and melt and plasticize through the single-screw extruder to obtain a flowable resin. The temperature gradient for melting and plasticizing is set at 185°C-205°C-218°C, and the die temperature is set at 215°C; then A high-brightness mirror steel roller and a finely ground rubber roller with a surface thickness of 1400 meshes are set through parallel pressure, cooled and shaped at 20°C; then edge trimming and corona treatment are performed, and the power of corona treatment is 500W , the extrusion speed is 30m / min; the final winding is to obtain a label film with a thickness of 70μm, hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com