Dust level monitoring alarm device for gravity dust remover of blast furnace and monitoring alarm method

A gravity dust collector, monitoring and alarm technology, applied to dust collectors, inspection devices, etc., can solve the problems of dust leakage, low dust volume of gravity dust collector, and inability to monitor and accurately display gravity dust collector in time, so as to ensure safety and stability The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, with reference to the drawings, through the description of the embodiments, the specific implementation of the present invention such as the shape and structure of the various components involved, the mutual position and connection relationship between the various parts, the function and working principle of each part, and the manufacturing process And the operation and use method, etc., are described in further detail to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concept and technical scheme of the present invention.

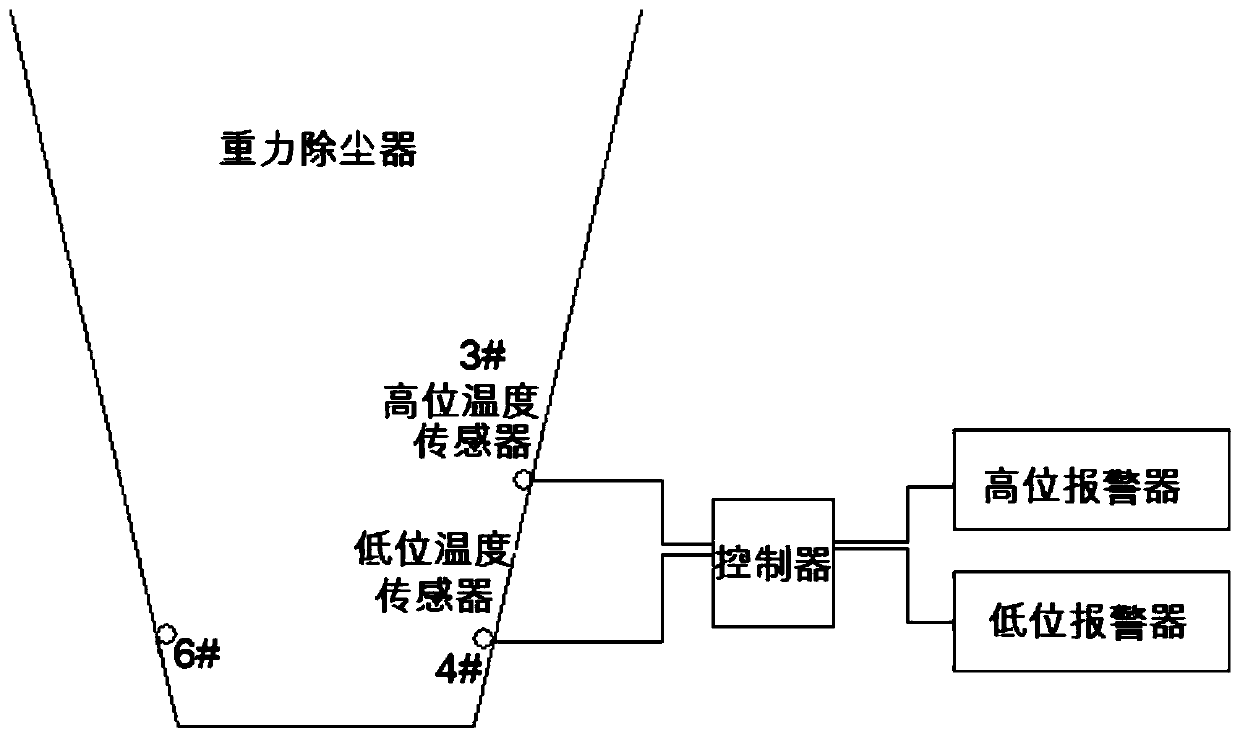

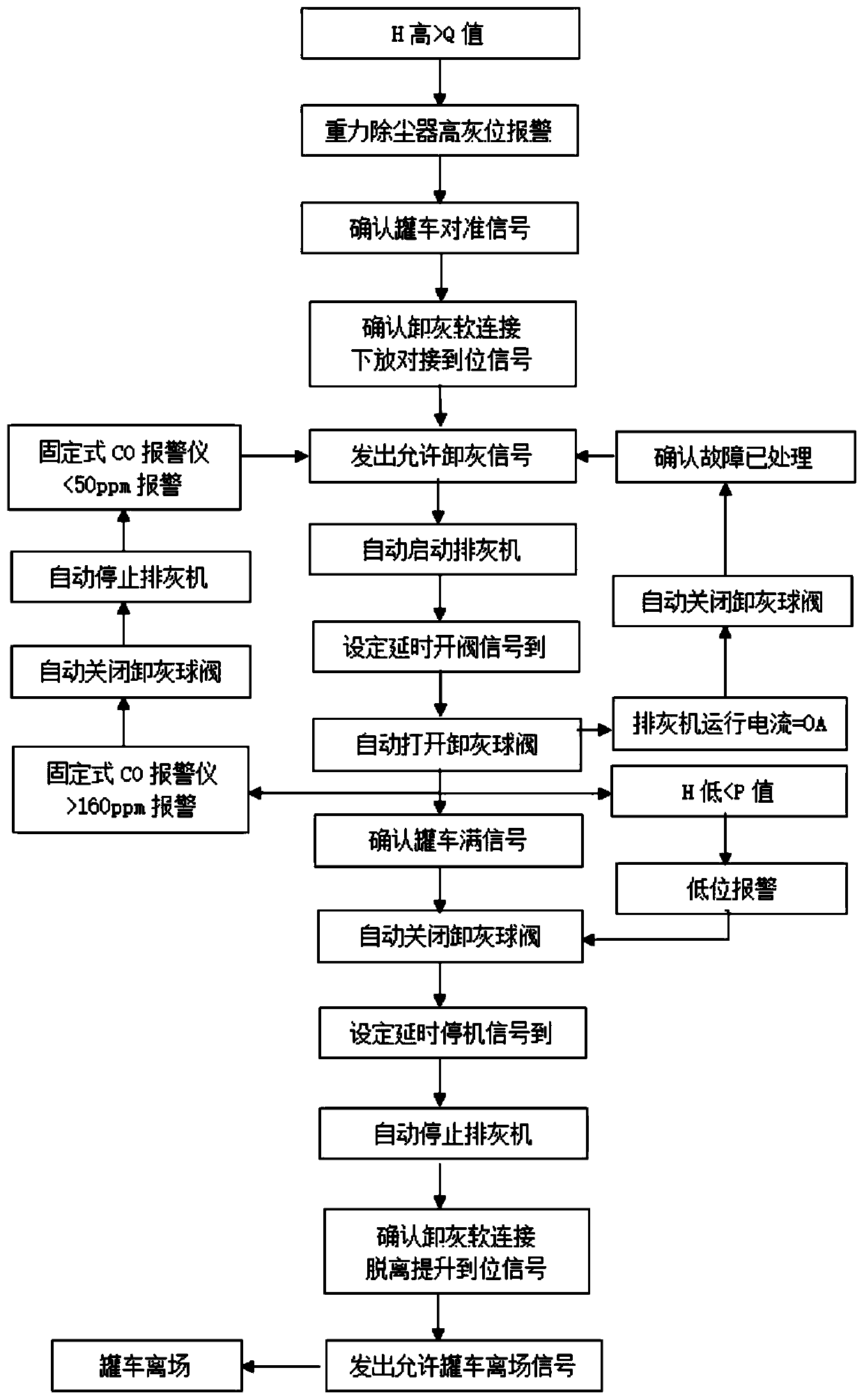

[0029] The invention uses the temperature measured by thermocouples (temperature sensors) installed at different positions in the vertical direction of the gravity dust collector to track. The temperature of the electric couple covered by gravity ash in the gravity dust collector gradually decreases due to the precipitation temperature of the gravity ash. It will be lower than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com