Washing machine filtering device and washing machine

A filter device and washing machine technology, applied in the field of washing machines and filter devices, washing machine filter devices and washing machines, can solve the problems of raising the overall center of gravity of the washing tub and the outer tub, destroying the washing tub, and increasing the weight of the upper part of the washing tub, so as to reduce the washing time. The effect of water consumption, saving washing water consumption and good washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

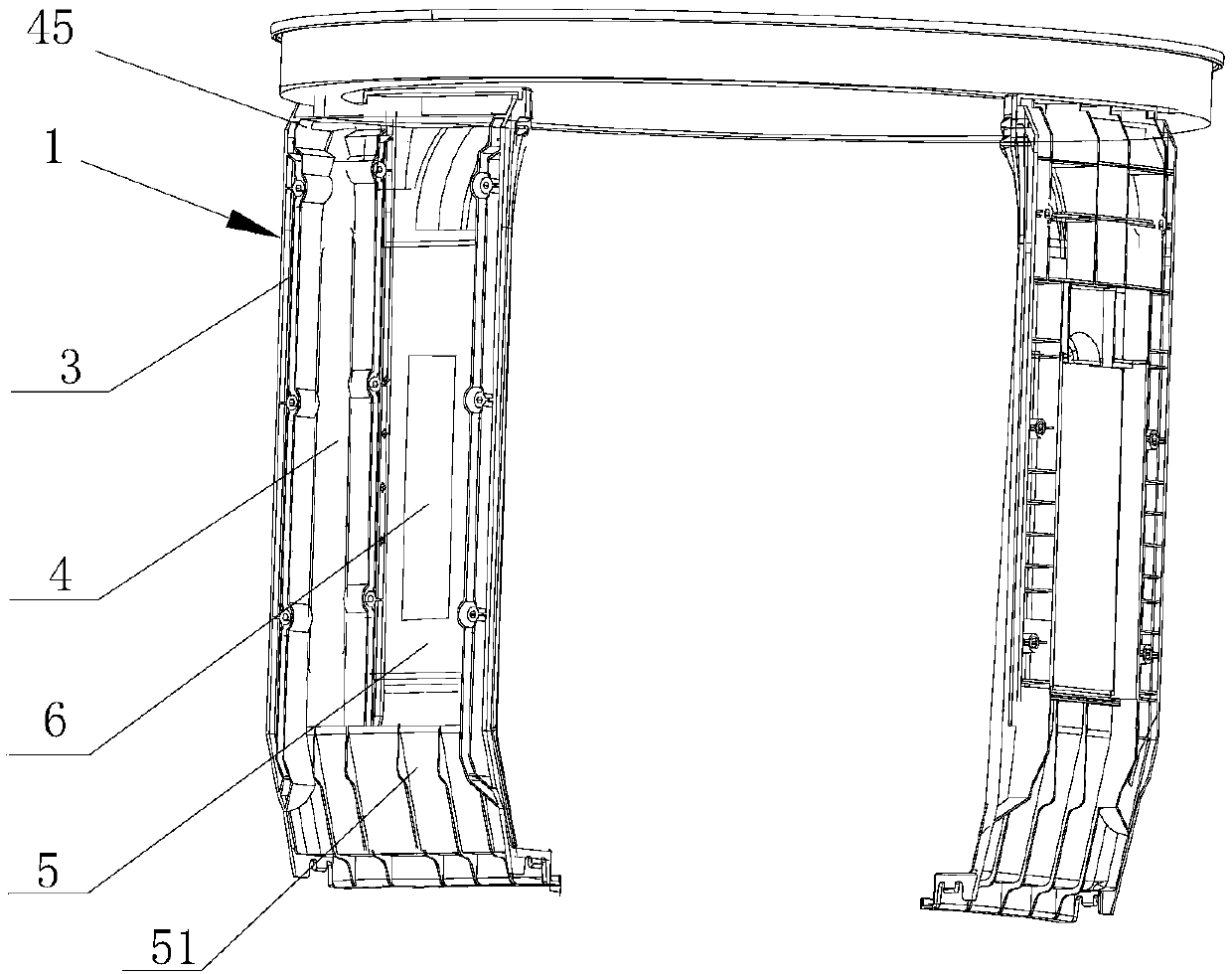

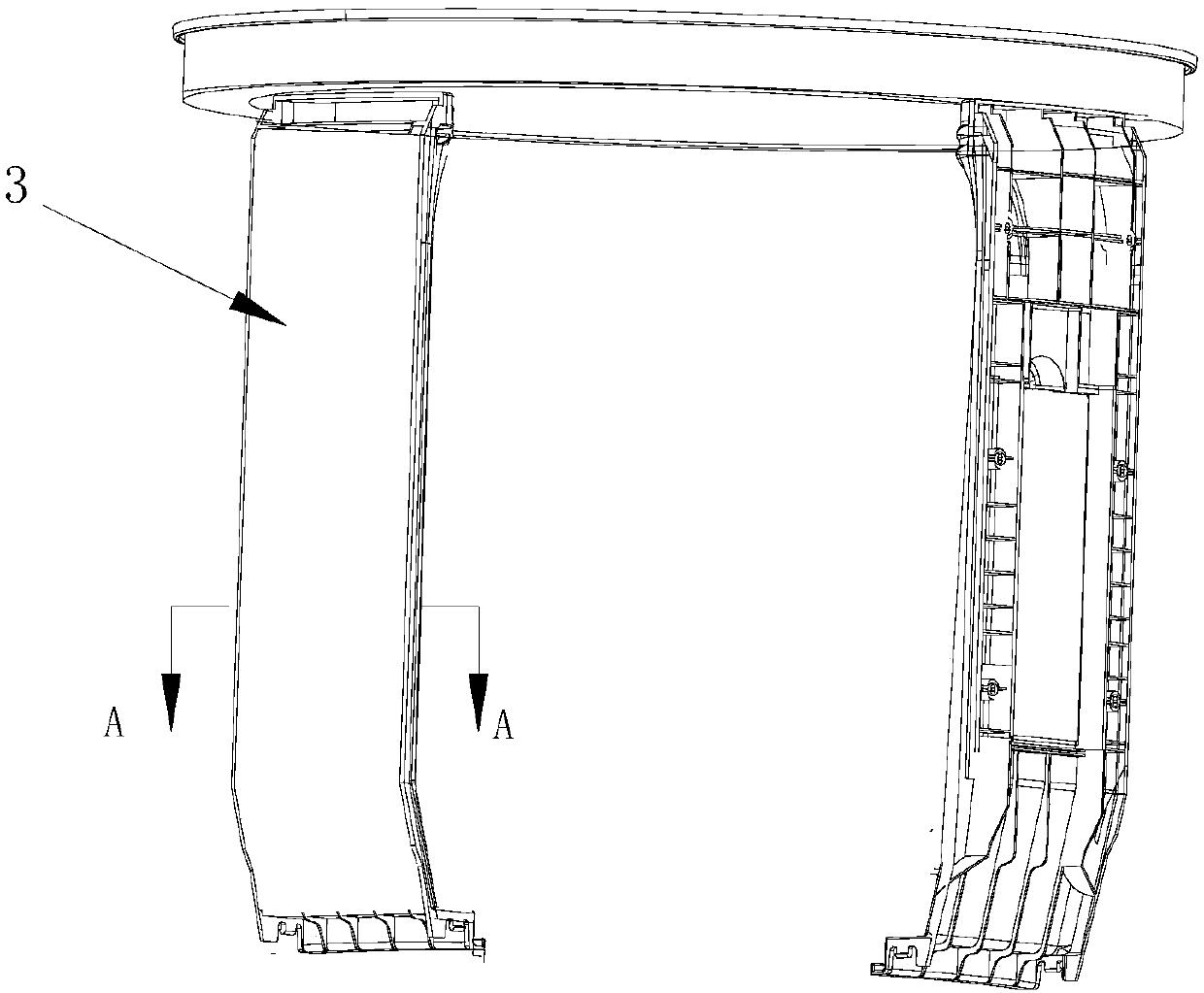

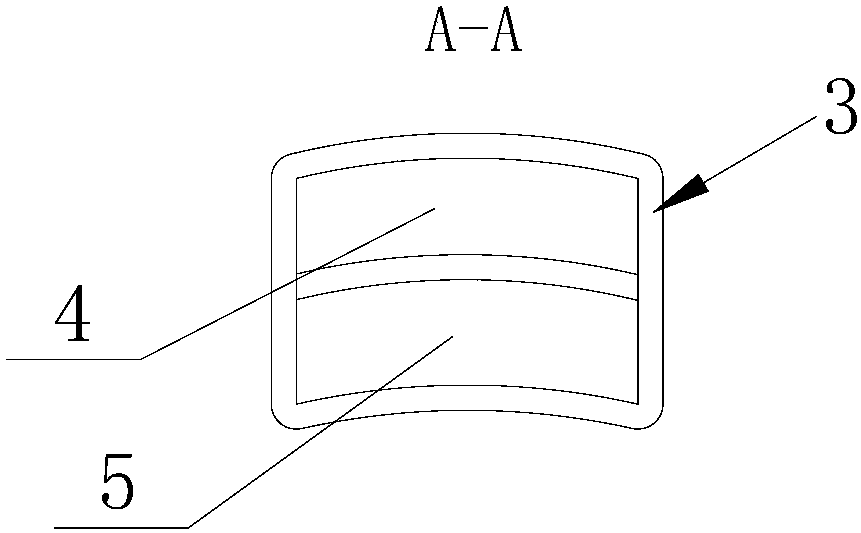

[0058] Such as image 3 As shown, the water guiding channel 4 and the filtering channel 5 described in this embodiment are distributed radially along the washing tub 2 on the mounting seat 3, and the water guiding channel 4 is arranged between the filtering channel 5 and the inner peripheral wall of the washing tub 2, also That is, the filter channel 5 is arranged at the position near the center of the washing tub 2 on the installation seat, and the water guide channel 4 is arranged at a position near the inner peripheral wall of the washing tub 2 .

[0059] The water guiding channel 4 described in this embodiment can be defined separately by the mounting base 3, that is, the mounting base 3 is provided with a channel for conducting water up and down, or the water guiding channel 4 is defined by the mounting base 3 and the inner peripheral wall of the washing tub 2. Commonly defined, the side wall of the mounting seat close to the inner peripheral wall of the washing tub and t...

Embodiment 2

[0061] Such as Figure 4 to Figure 6 As shown, the water guide channel 4 and the filter channel 5 described in this embodiment are distributed along the circumferential direction of the washing tub 2 on the mounting seat. Since the water guide channel 4 conducts water from top to bottom, the filter channel 5 filters water from bottom to top , so the water guide channel 4 must have a waterway with the same height as the filter channel 5, which can be set as follows:

[0062] Option one: the water guide channel 4 has a section of waterway with the same height as the filter channel 5, which is located on one side of the filter channel 5 (see Figure 4 ).

[0063] Option two: the water guide channel 4 has two branches 43, 44 at the same height as the filter channel 5, which are respectively located on both sides of the filter channel 5 (see Figure 5 ).

[0064] Alternatively, also have a structure: such as Figure 6 As shown, the water guiding channel 4 and the filtering chan...

Embodiment 3

[0066] Such as Figure 7 to Figure 8 As shown, a washing machine of the present invention includes a box body 7, a washing bucket 2 rotatably arranged in the box body 7, the washing bucket 2 is configured as a bucket structure for holding water during washing, and the inner peripheral wall of the washing bucket 2 The filter device 1 in the above-mentioned embodiment is installed on it. The washing machine also includes a water receiving device 8 arranged in the casing 7 for collecting the water discharged from the washing tub. The water receiving device 8 is arranged at the lower part of the washing tub 2 and includes a water collecting cavity 81 and at least one second drain 82 for draining outwards. The water collection chamber 81 can collect the washing water discharged from the washing tub 2, and the peripheral wall 83 defining the water collecting chamber surrounds at least the peripheral wall of the lower part of the washing tub 2. In order to improve the expansion effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com