Speed reduction clutch device of washing machine, washing machine and control method of washing machine

A clutch device, washing machine technology, applied in the control device of the washing machine, washing device, other washing machines and other directions, can solve the problems of wasting height space, unfavorable expansion of the whole washing machine capacity, limited improvement of clothes washing effect, etc., to avoid clothes entanglement , improve cost performance and good experience, and achieve the effect of expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

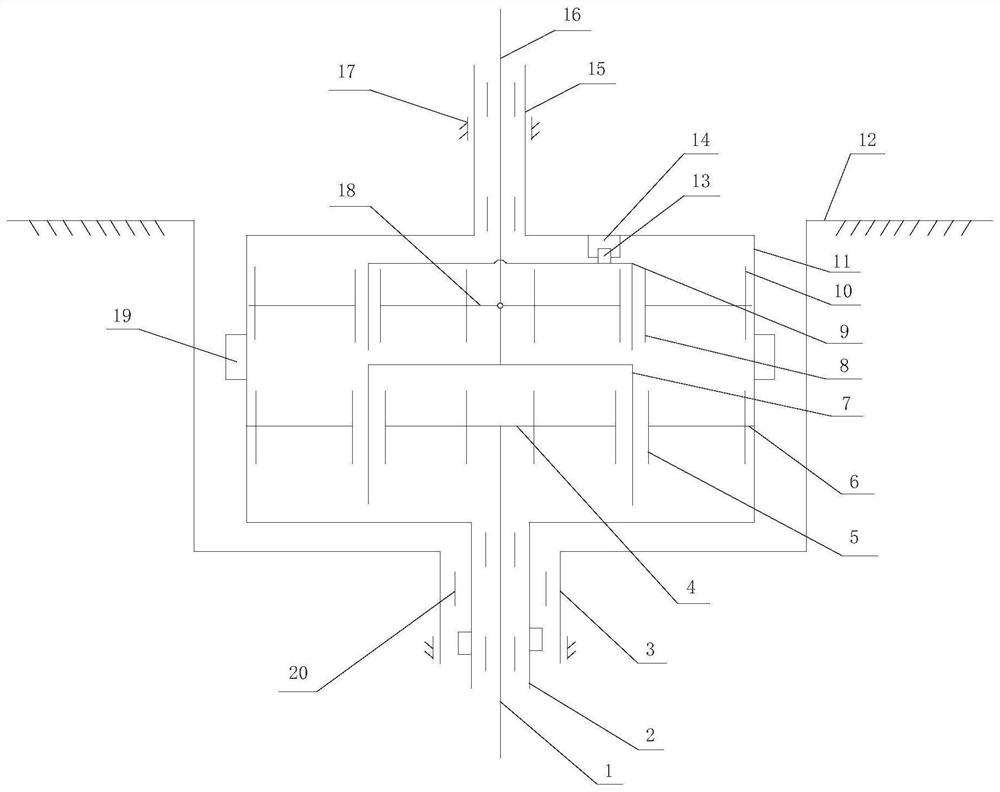

[0036] A deceleration clutch device for a washing machine, a washing machine and a control method thereof of the present invention are described in detail below in conjunction with the accompanying drawings:

[0037] Such as figure 1 As shown, the present embodiment provides a deceleration clutch device for a washing machine, including:

[0038] The gear box 11 has an accommodating chamber inside;

[0039] The gear train is arranged in the accommodation chamber in the gearbox, and the gear train includes a first planetary gear train and a second planetary gear train;

[0040] The input shaft 1 is connected to the first sun gear 4 of the first planetary gear train;

[0041] The input shaft sleeve 2 is sleeved on the input shaft 1 and connected to the gear box 11;

[0042] The output shaft 16 is connected to the first planetary carrier 7 of the first planetary gear train;

[0043] And the output shaft sleeve 15 is sleeved on the output shaft 16 and connected to the gear box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com