Visual MoSi2 heating element furnace hearth device for interaction study of molten metal and water

A technology for visualizing silicon molybdenum and molten metal, applied in descaling devices, furnaces, furnace linings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

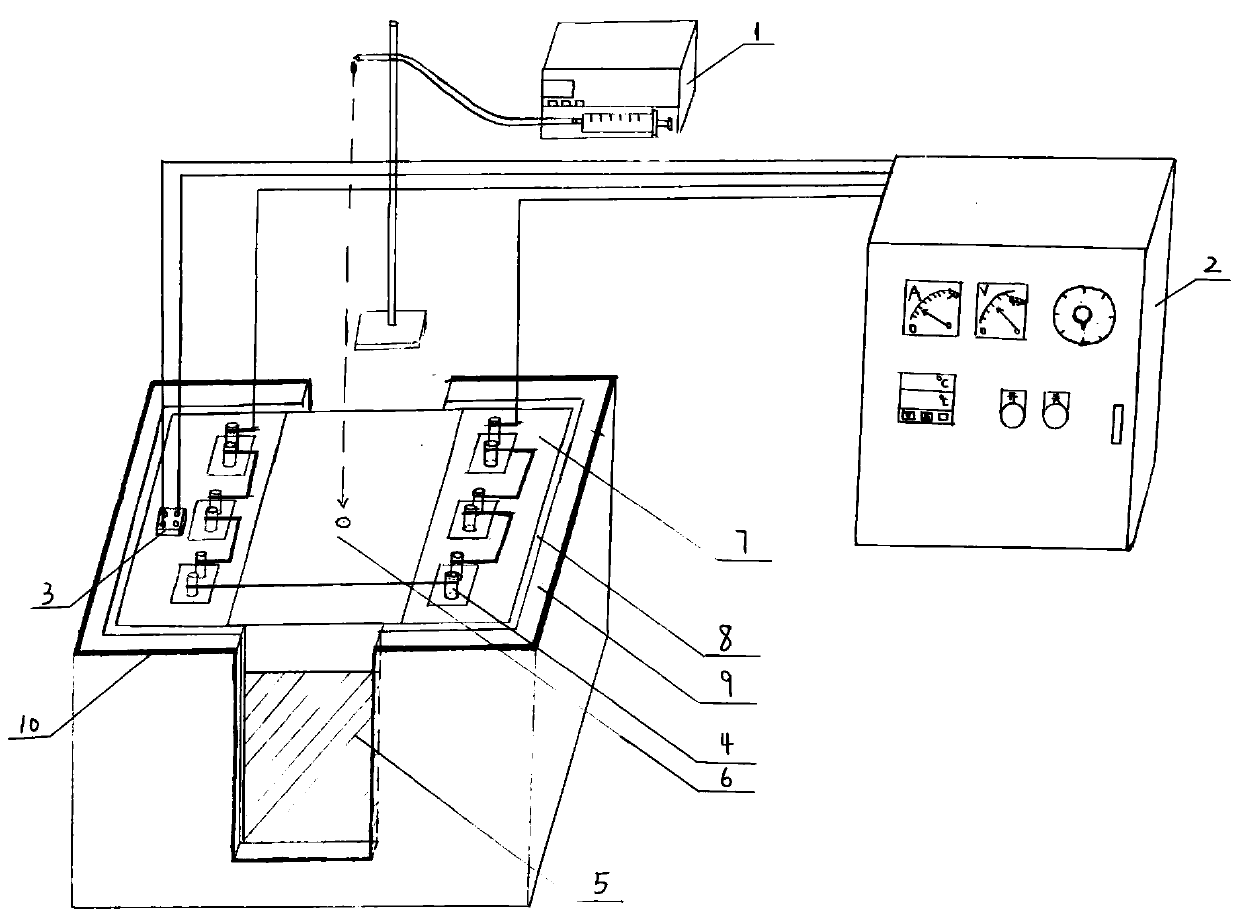

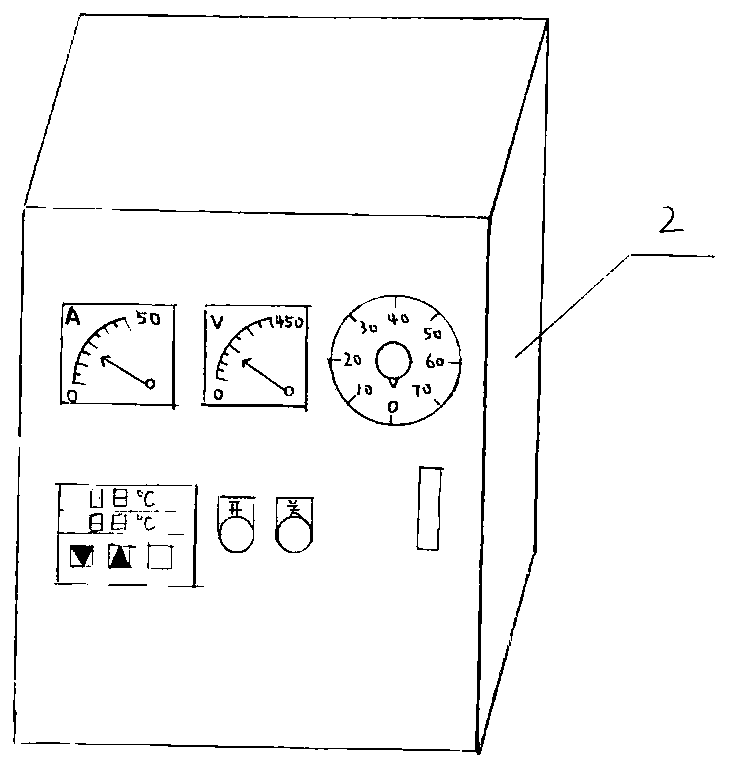

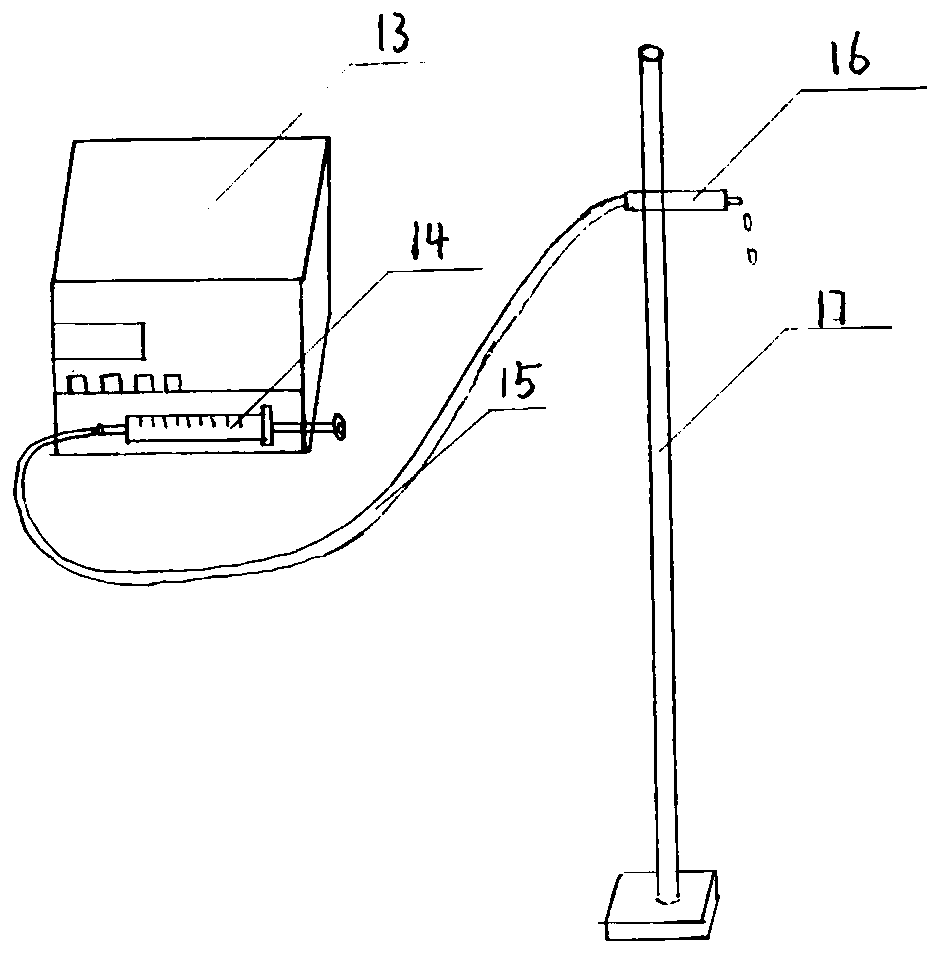

[0043] like Figure 1-12As shown, a visualized silicon-molybdenum rod furnace device for research on the interaction between molten metal and water in this embodiment can be applied to the study of water droplets dripping into high-melting point molten metal, including silicon-molybdenum rod heating furnace system and water injection device system, water injection The device system is placed directly above the silicon-molybdenum rod heating furnace system, wherein the silicon-molybdenum rod heating furnace system includes a crucible 5, and the cruci...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap