A Method of Improving Burgers Rock Shear Creep Model

A rock and model technology, applied in the direction of testing the ductility of materials, instruments, measuring devices, etc., can solve the problems of weakness, rock mass shear strength attenuation, etc., and achieve the effect of simple model parameters and clear physical and mechanical meanings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

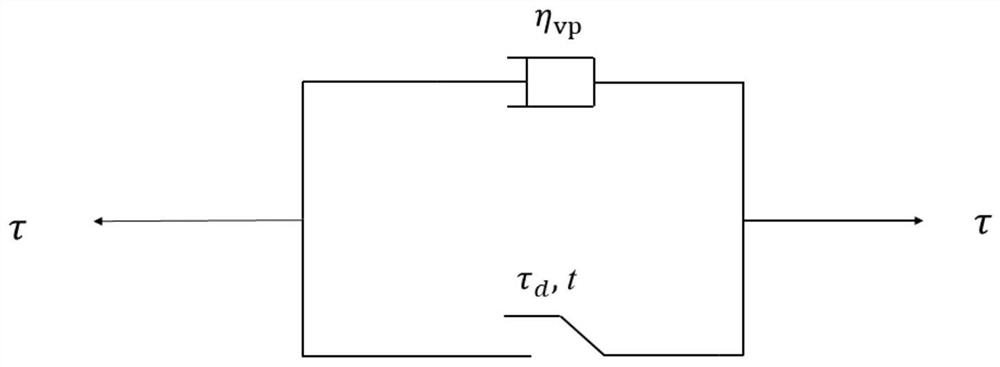

[0067] S1. Aiming at the time difference of rock shear strength in the creep state, construct a nonlinear element which is composed of a plastic element and a viscous element in parallel to describe the mechanical properties of the rock in the accelerated creep stage (such as figure 2 shown), where the plastic component parameter τ d It represents the actual shear strength of the rock, and its value changes with time. The viscous element represents the shear strain rate of the rock, and the parameter η is linearly constant.

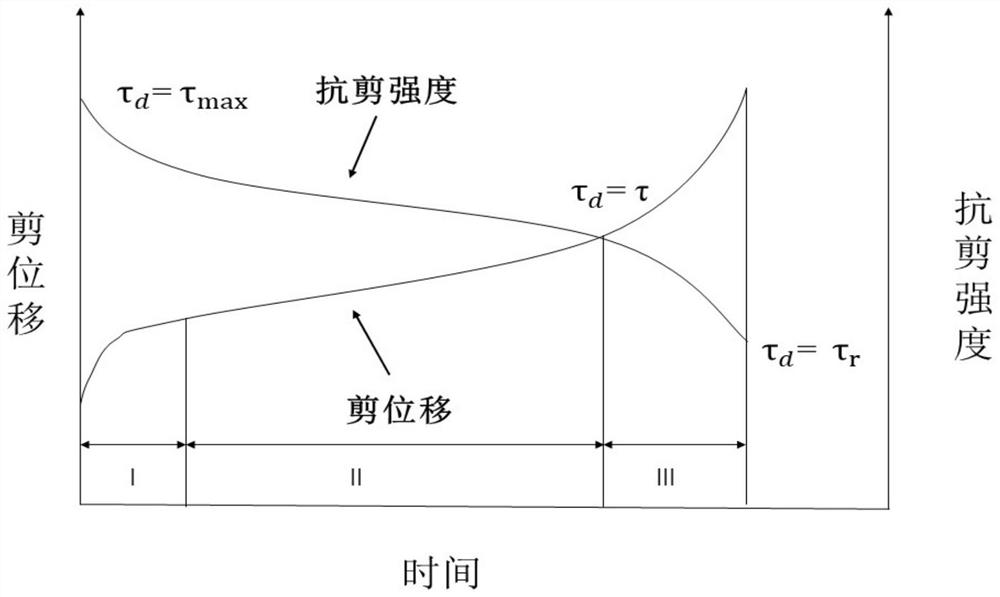

[0068] refer to figure 1 , the creep process can be divided into three stages: I—attenuation creep stage, II—stable creep stage, III—accelerated creep stage. When the external load exceeds the yield strength of the rock, internal micro-cracks begin to initiate and develop, causing damage over time and deterioration of continuity, resulting in the shear strength τ d Constantly decaying. When the external stress τ exceeds the long-term strength of the r...

Embodiment 2

[0121] Embodiment 2 Test example verification

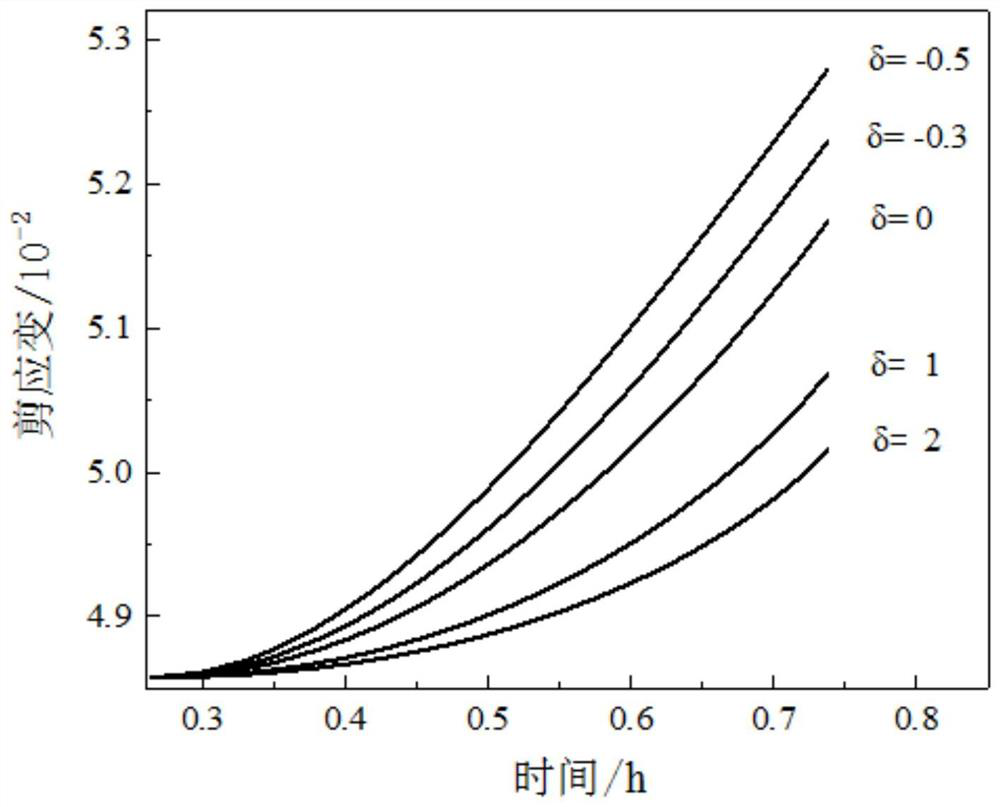

[0122] Substituting the laboratory test data into the constitutive equation of the improved Burgers modelγ B (t), and determine its long-term strength τ s , the validity and rationality of the model are verified by experiments, and the rock microscopic damage characteristics are obtained through the inversion parameter δ.

[0123] In order to verify the rationality of the improved Burgers model proposed by the present invention, a sandstone sample is selected for indoor creep shear test. The sample size is 10cm×10cm×10cm. The specific mechanical parameters are shown in Table 1. According to other tests on sandstone, it can be known that the long-term shear strength under the normal stress condition of 1.56MPa is 2.8-3MPa. In order to obtain the test curve including the accelerated creep stage, the loading shear stress is set to be 3.36MPa greater than the long-term shear strength.

[0124] Table 1 Sandstone material parameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com