A Creep Strength Test Method Based on Acoustic Emission Activity Analysis

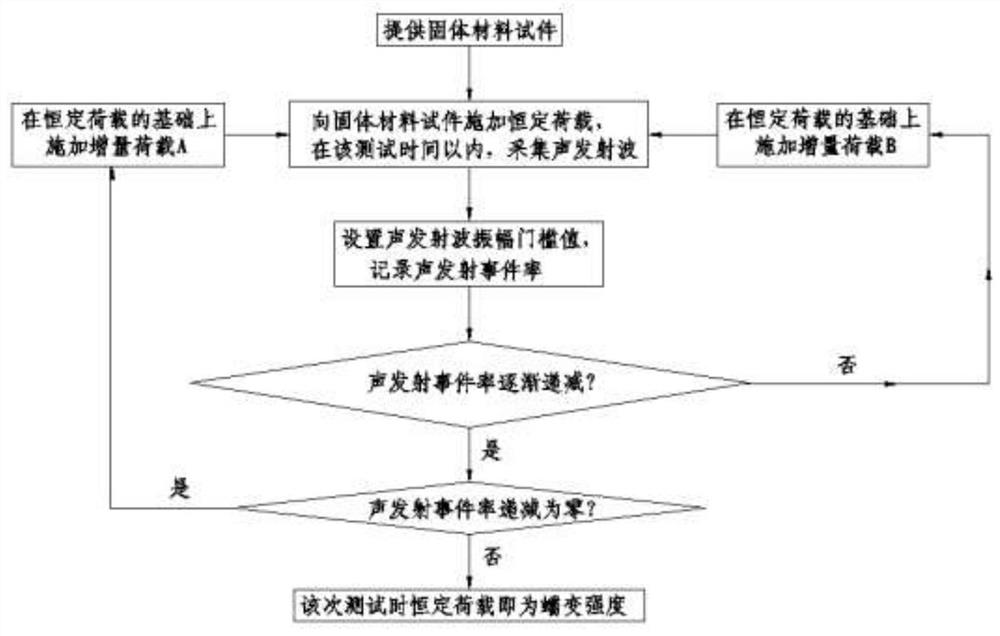

A technology of creep strength and testing method, which is applied in the field of acoustic emission, can solve problems such as inability to judge, high time cost, and spending days or months, so as to improve measurement accuracy, reduce test time cost, and improve test efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

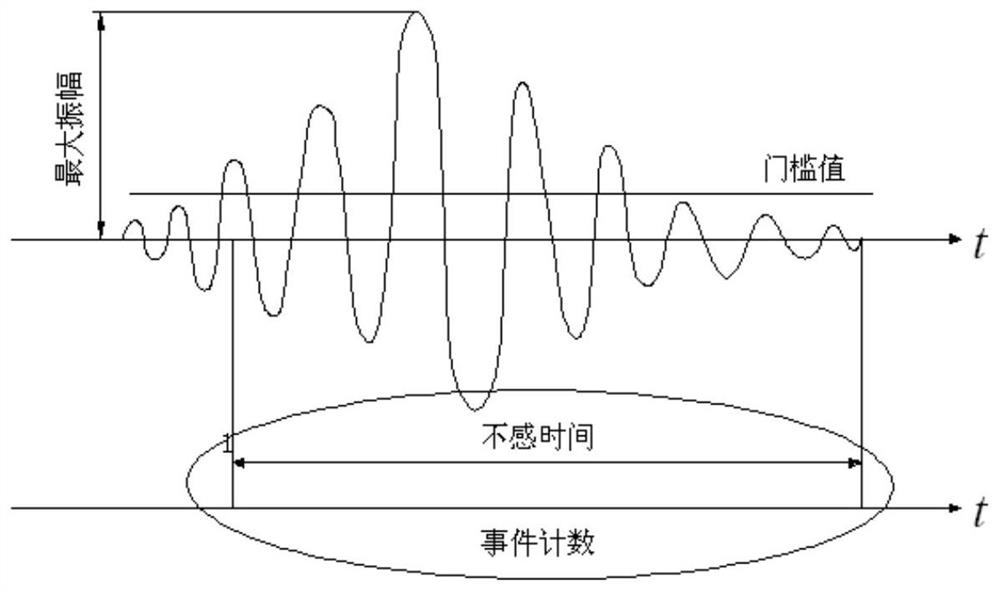

[0039] The parameters of the solid material acoustic emission wave involved in the present invention mainly include: amplitude, threshold value, duration, acoustic emission event, such as image 3 As shown in the figure, the acquisition of the characteristic parameters of the acoustic emission wave waveform is based on the threshold value, and each parameter is specifically defined as follows:

[0040] 1) Amplitude, refers to the displacement of the waveform vibration to the displacement at rest;

[0041] 2) Threshold value, which refers to an amplitude value that is artificially set to collect acoustic emission waveforms;

[0042] 3) Duration, refers to the time interval that the acoustic emission waveform number crosses the threshold value for the first time until it finally falls to the threshold;

[0043]4) Acoustic emission event, which means that after setting a threshold amplitude, when the amplitude exceeds the amplitude value, it is counted, and the time that no long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com