Off-line oil granularity detecting system and detecting method

A detection system and particle size technology, applied in particle size analysis, particle suspension analysis, particle and sedimentation analysis, etc., can solve the problems of counter calibration difficulties, test result repeatability, low test efficiency, etc., to improve oil sample monitoring frequency and position, improve the effect of oil monitoring, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

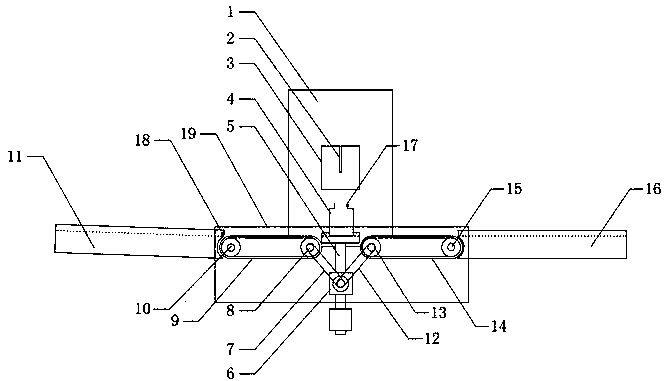

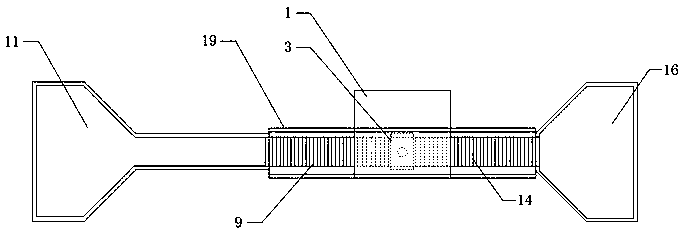

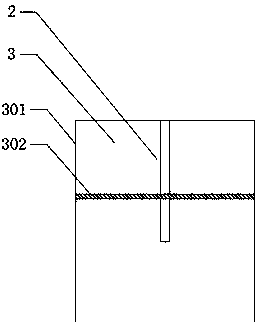

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0040] figure 1 , 2 Shown is an off-line oil particle size detection system provided by the present invention, including an oil particle size detector 1 and an oil sample transmission system, the oil sample transmission system consists of a lifting device 5, a conveyor belt motor 6, and a transmission belt A7 , driving shaft A8, conveyor belt A9, driven shaft A10, oil sample waiting platform 11, transmission belt B12, driving shaft B13, conveyor belt B14, driven shaft B15 and oil sample bottle detection platform 16. The conveyor belt A9 is wrapped around the driving shaft A8 and the driven shaft A10, the driving shaft A8 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com