Fast clamping and installing device for plate machining

A plate processing and clamping technology is applied in the field of rapid clamping devices for plate processing, which can solve the problems of time-consuming, labor-intensive, and high production costs, and achieve the effects of simple and practical operation, easy removal of plates, and labor and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

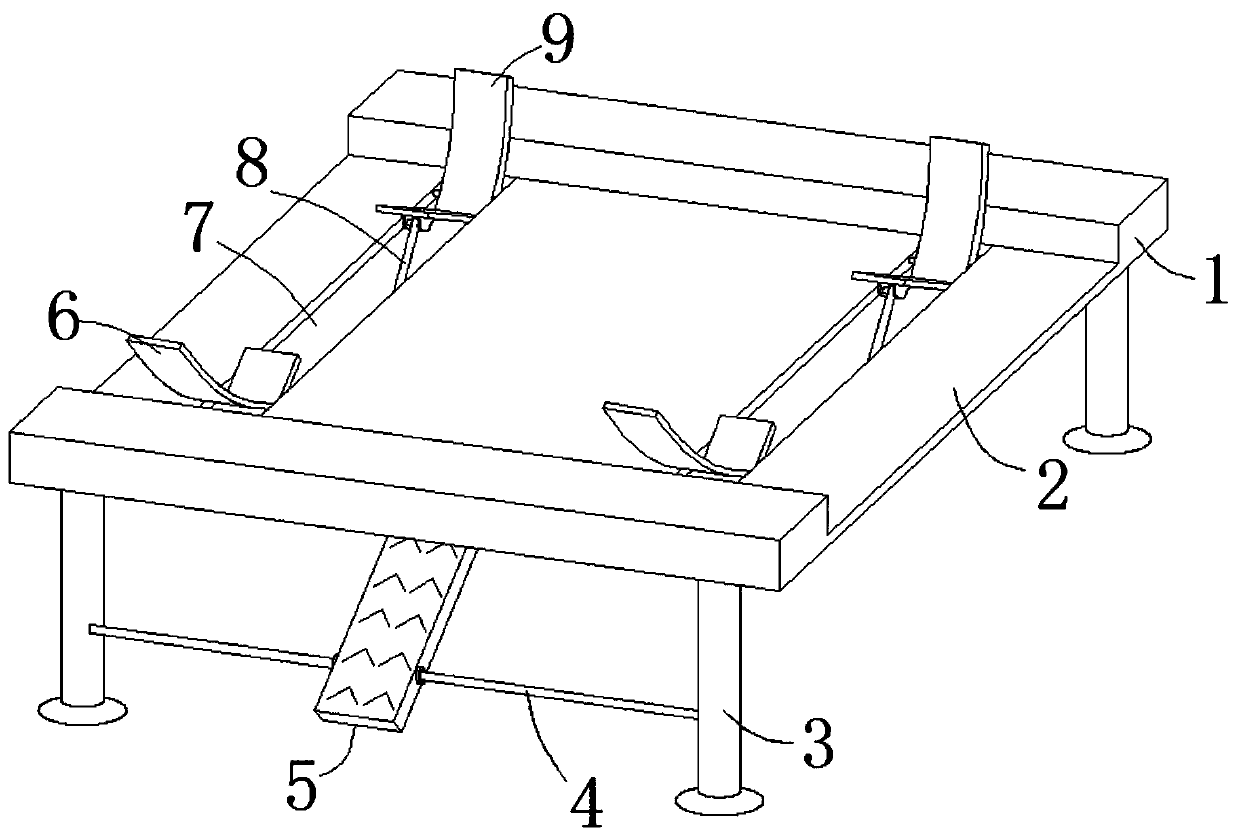

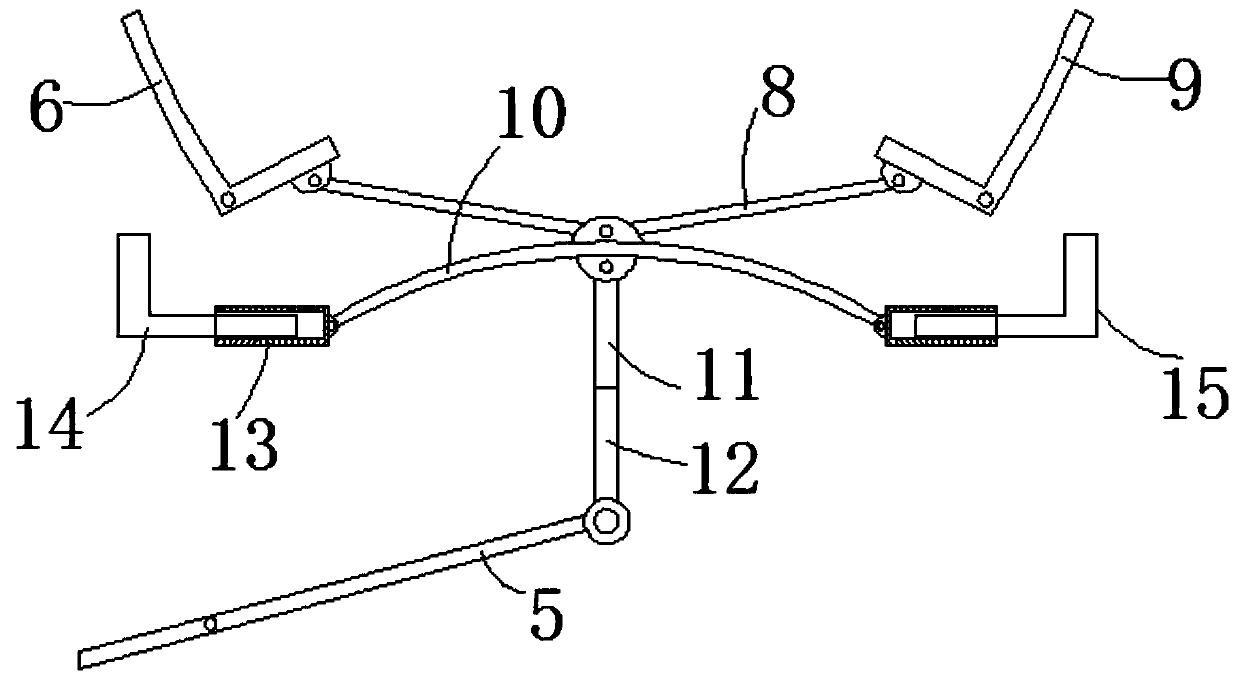

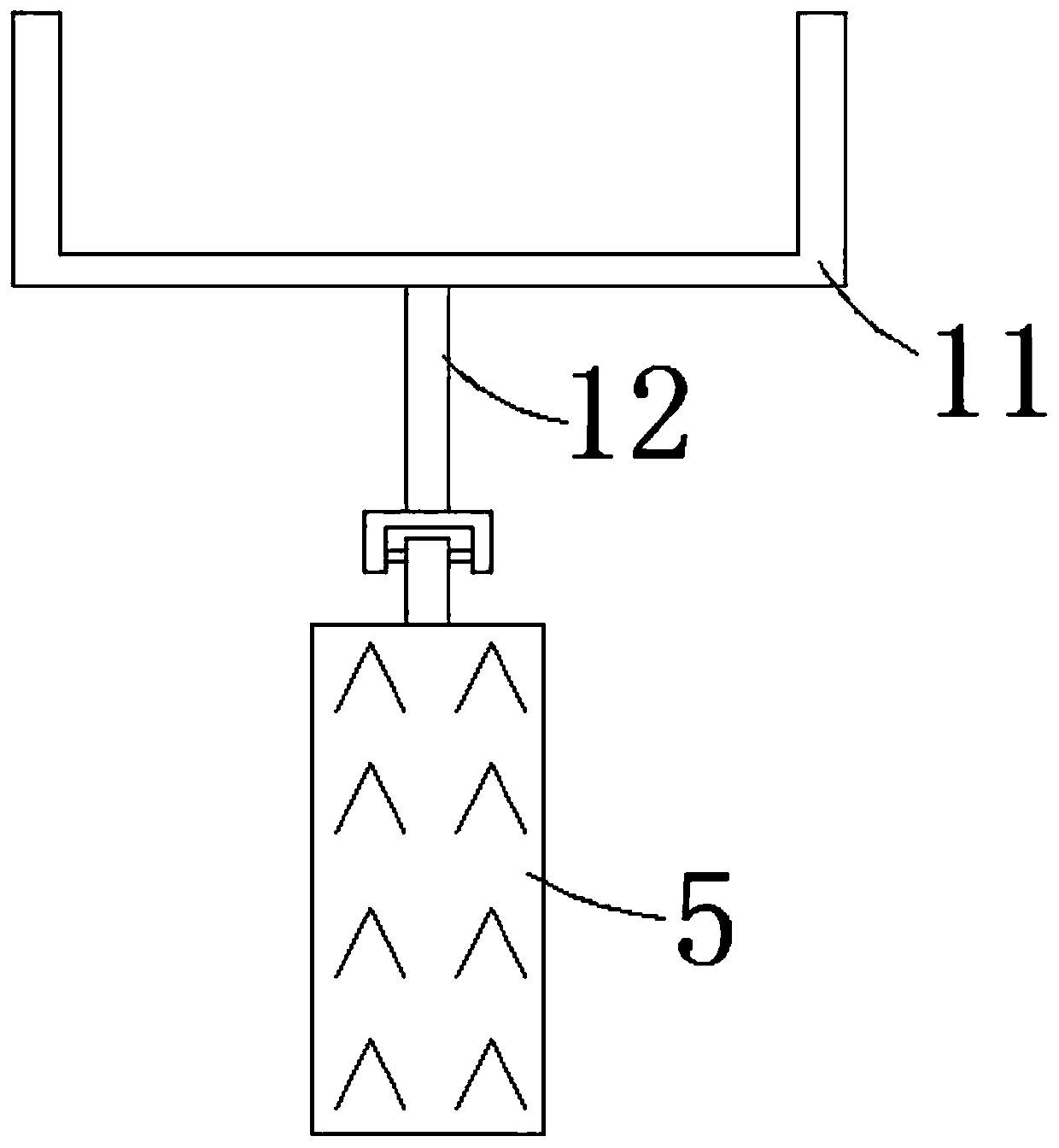

[0019] see Figure 1-3 , the present embodiment provides a quick clamping device for plate processing, including a clamping table 1, the four corners of the bottom end surface of the clamping table 1 are vertically welded with supporting legs 3, between the two supporting legs 3 on the front side A supporting roller 4 is arranged horizontally, and the middle section of the supporting roller 4 is rotatably fitted with a pedal 5 . The left and right sides of the bottom end surface of the cavity are symmetrically provided with rectangular holes 7, and the front and rear sides of the inner cavity of the two rectangular holes 7 are respectively provided with a first splint 6 and a second splint 9 that can rotate back and forth, two first splints 6 and two The second splint 9 is arranged symmetrically front and back respectively, and the bottom end faces of the two first splints 6 and the two second splints 9 are all rotated to be provided with hinged rods 8, and the bottom face of ...

Embodiment 2

[0022] see Figure 1-3 , made a further improvement on the basis of Example 1: the two first splints 6 and the two second splints 9 are L-shaped, and the opposite side walls are all arranged in an arc shape, so as to prevent the first splint 6 and the When the second splint 9 clamps the plate, the plate slides upwards, which makes it inconvenient to process the plate. The first sliding frame 14 and the second sliding frame 15 are both L-shaped, which is convenient for sliding use with the buffer sleeve 13. The first sliding There are two racks 14 and second sliding racks 15, which are respectively located on the front and rear sides of the two rectangular holes 7, so that the two arc-shaped stainless steel elastic sheets 10 can be used to drive the buffer sleeve 13 to slide.

[0023] Wherein, the bottom end surfaces of four supporting legs 3 are all provided with anti-slip pads, by setting anti-slip pads to prevent displacement in the clamping process, the upper end surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com