Double-cross-beam side-by-side multi-rotor helicopter

A multi-rotor, double beam technology, applied in the field of helicopters, can solve problems such as large occupation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

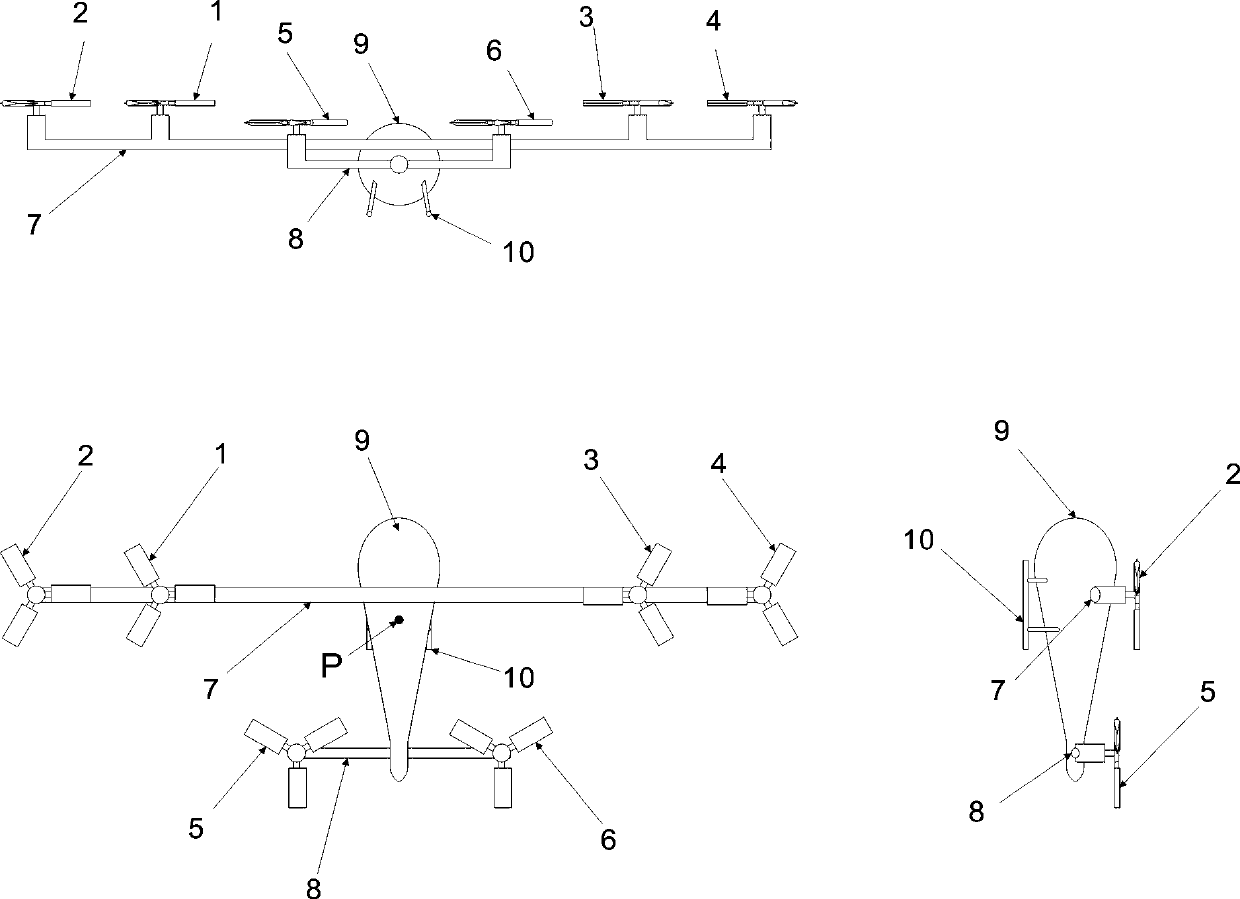

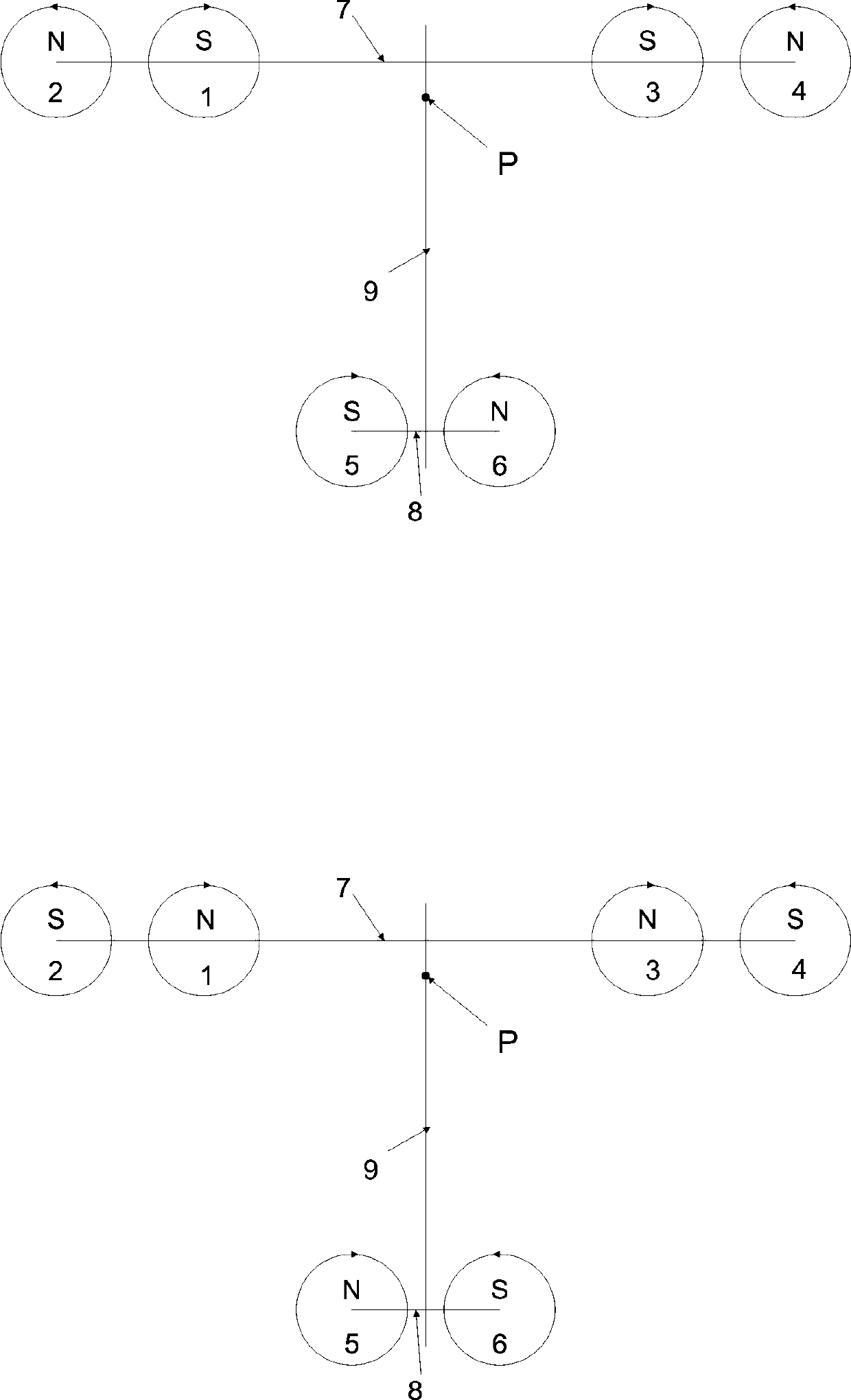

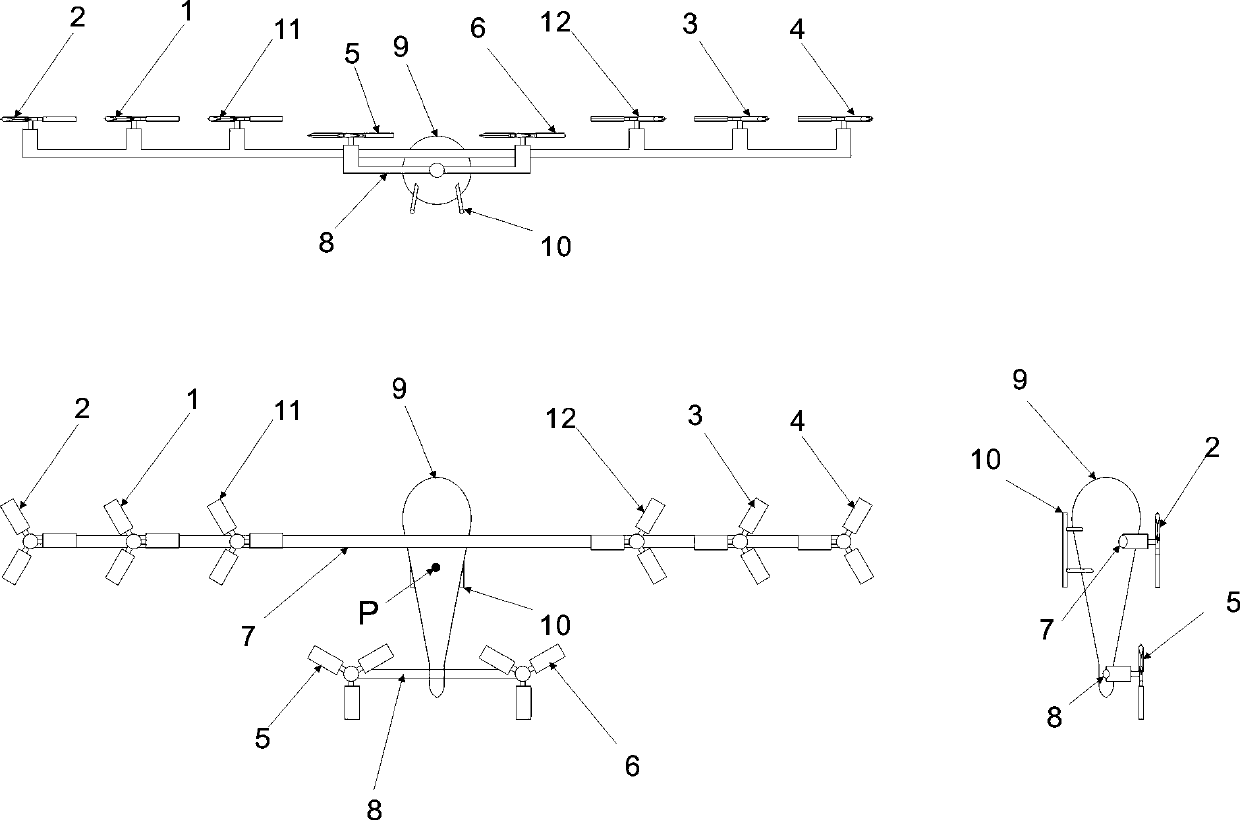

[0032] figure 1 In the shown embodiment, the first beam (7) is set in front of the center of gravity (P) on the top of the fuselage (9), the second beam (8) is set at the rear of the fuselage (9), and the center of gravity (P) is near the center of gravity (P) under the fuselage (9). Set the landing gear (10).

[0033] On the left side of the first crossbeam (7) close to the longitudinal direction of the fuselage, the first rotor (1) on the left side of the first crossbeam (1) is arranged, and on the left side of the first crossbeam (7) away from the longitudinal direction of the fuselage, that is, the first rotor (1) on the left side of the first crossbeam ) to the left of the first crossbeam (2) on the left; on the right side of the first crossbeam (7) close to the longitudinal direction of the fuselage, the first rotor (3) on the right side of the first crossbeam (3) is set, and on the right side of the first crossbeam (7) away from In the longitudinal direction of the fus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com