Welding wire coil recycling device

A technology of recycling device and wire reel, applied in the field of wire reel recycling device, can solve the problems of increasing transportation cost and receiving efficiency, inconvenient management and maintenance of inventory information, and inability of delivery time to meet the needs of workers, etc., so as to achieve recycling. The effect of automation, easy monitoring, and saving management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

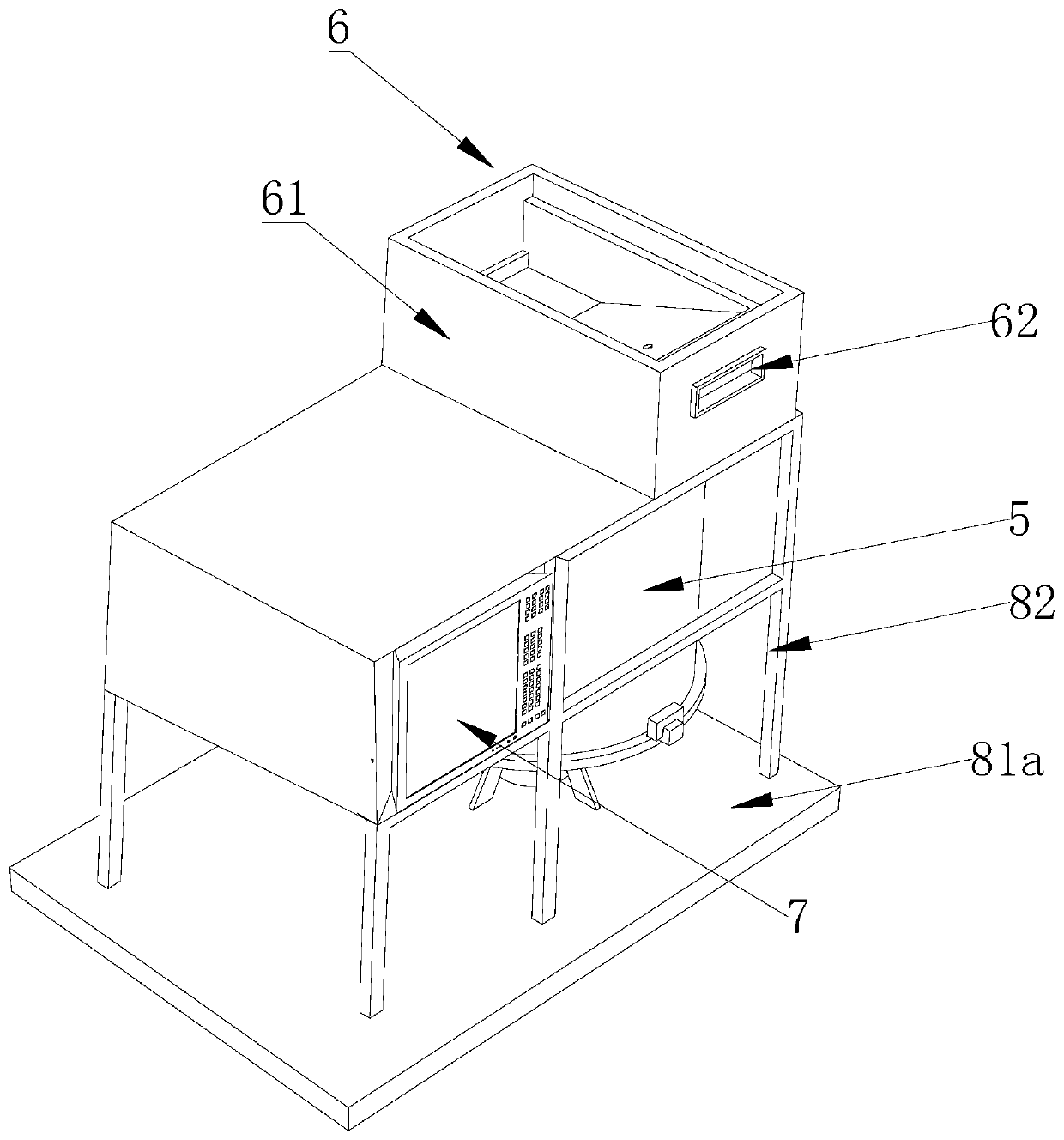

[0040] see Figure 1-10 , the figure shows that the wire reel recovery device of the present invention comprises:

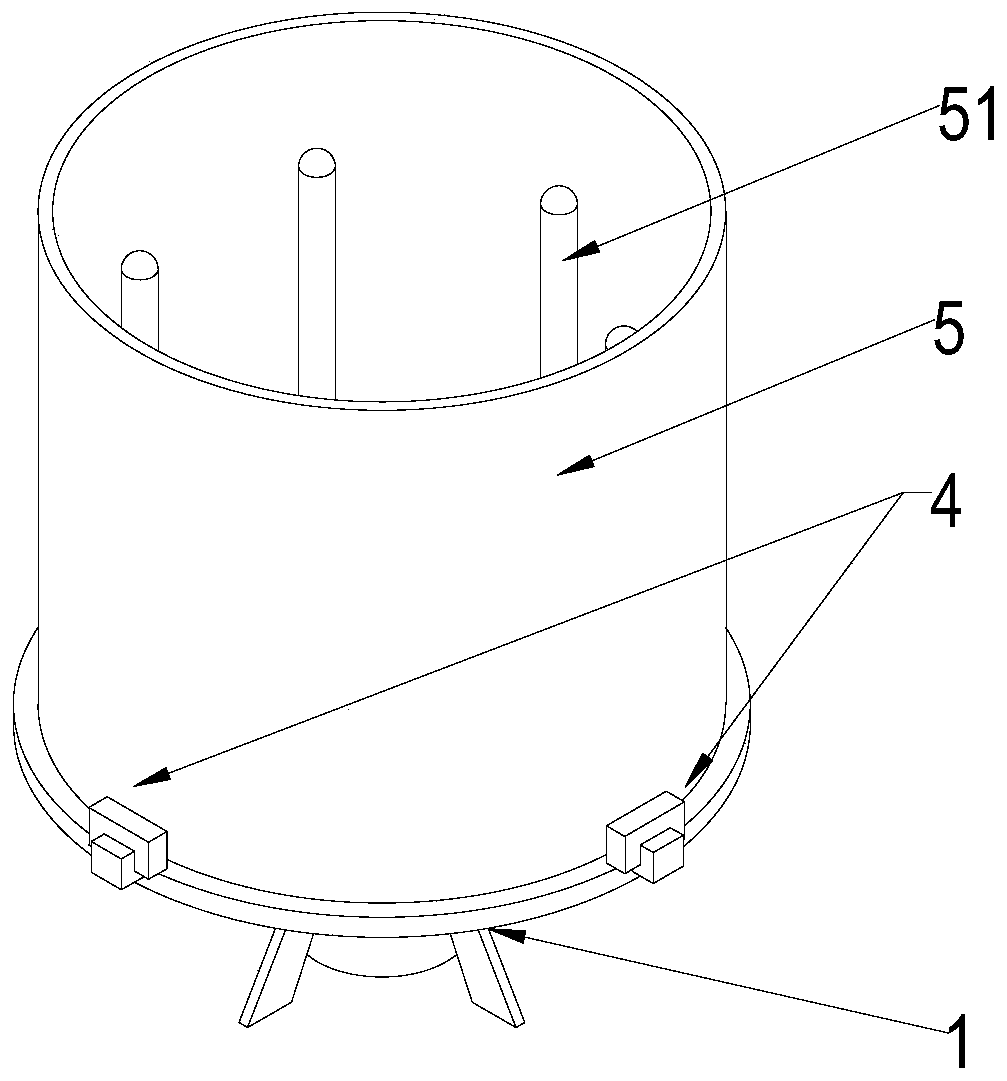

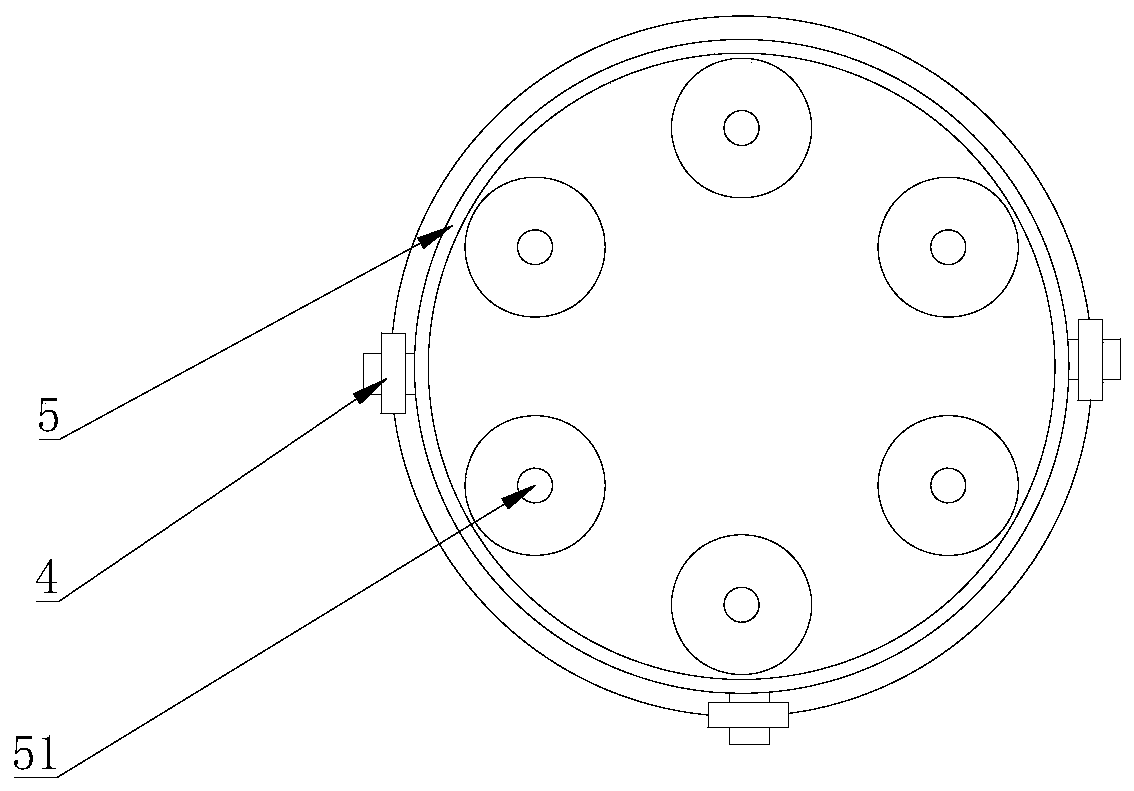

[0041] A drive base 1, which includes a servo motor 2 and a planetary gear mechanism 3 connected to the servo motor 2 through a driver, wherein the planetary gear mechanism 3 includes: a sun gear 31 connected to the driver, six evenly distributed on the sun gear A planetary gear 32 around the wheel 31 and meshed with it, a planetary carrier 33 mounted on the planetary wheel 32 to connect all the planetary wheels 32, and a ring gear 34 arranged around all the planetary wheels 32 and meshed with it;

[0042] A tank 5 that is detachably connected to the ring gear 34 through three connection locks 4 has six guide rods 51 corresponding to the positions of the planetary gears 32 on its inner bottom surface. After a guide rod 51 has received twelve waste weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com