Shuttle track pair

A track pair and shuttle technology, which is applied in the field of shuttle track pairs, can solve problems such as unsatisfactory positioning of the shuttle, limited width of the main roller, and easy winding of the warp, so as to avoid high-load heating, reduce unit load, and meet precision requirements. required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

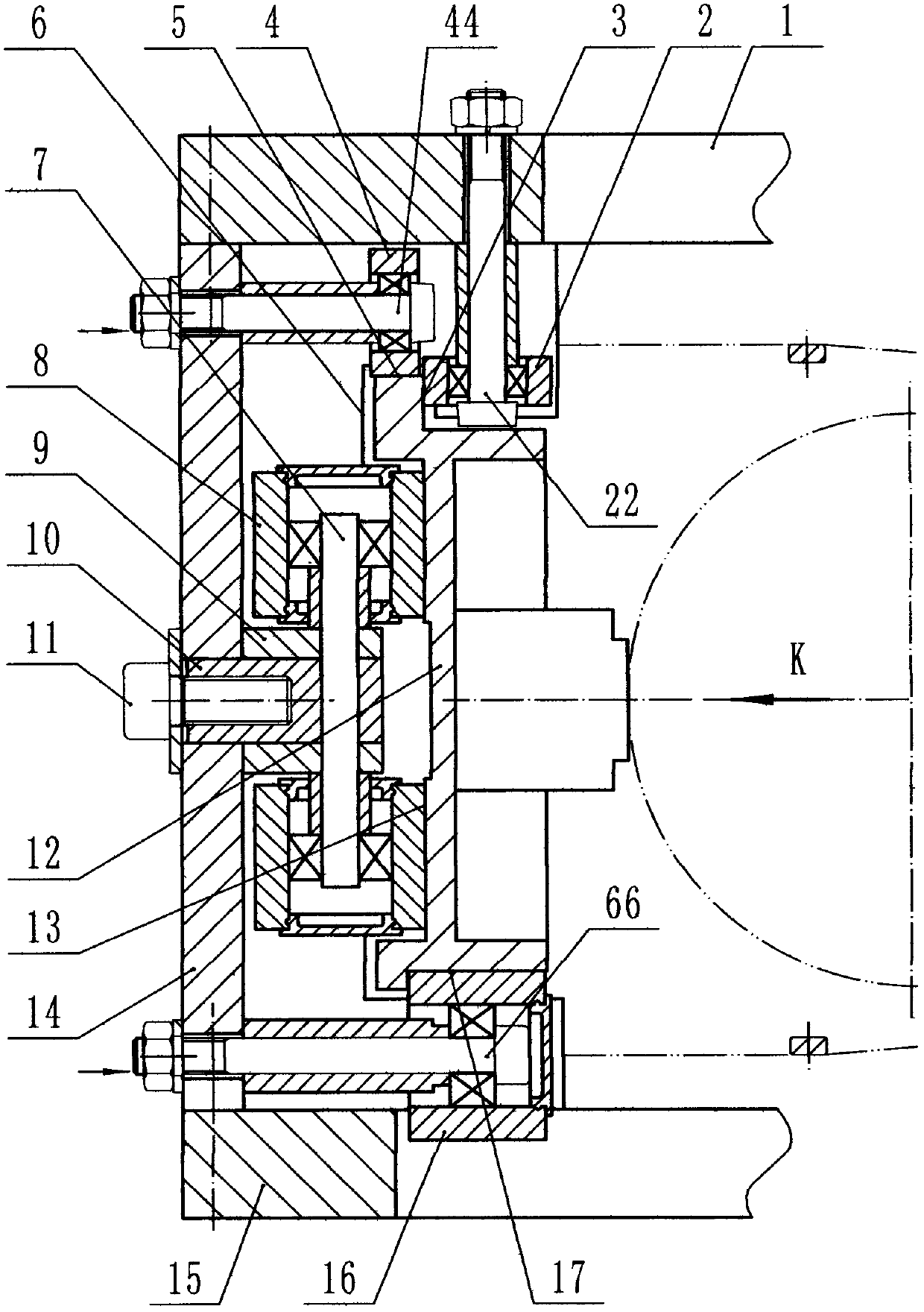

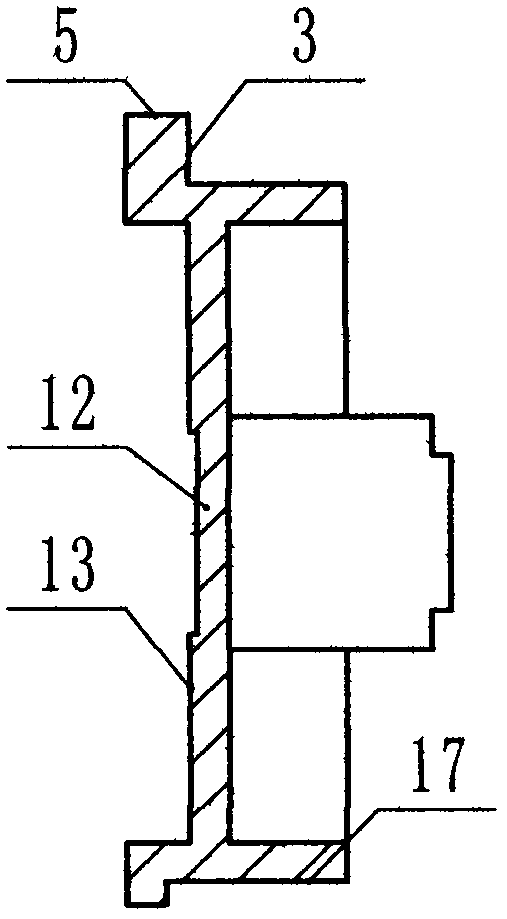

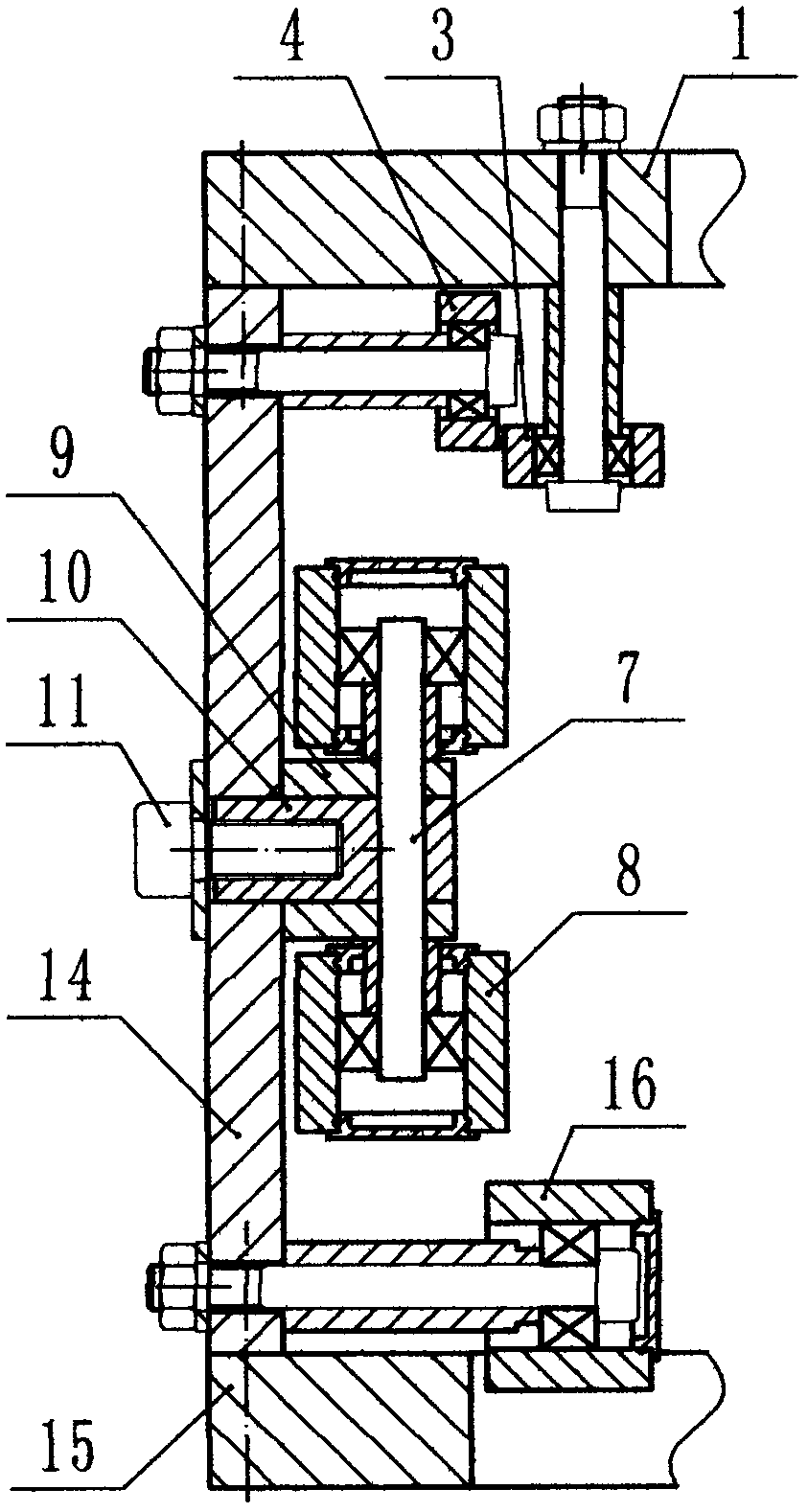

[0024] Such as Figure 1-4 As shown, the shuttle track pair of the small six-shuttle plastic circular loom includes an upper door ring (1), a lower door ring (15), and 6 shuttles (12), and also includes a ring that is arranged evenly along the circumference between the upper door ring and the lower door ring. 36 columns (14), 36 rollers A (2) on the upper door ring and roller B (4), roller C (8) and roller D (16) on the column are the cross sections of the rectangle. There are corresponding raceway A(3), raceway B(5), raceway C(13) and raceway D(17), respectively rolling and cooperating with rollers A, B, C and D to form a pair of shuttle running tracks, The axes of roller A(2) and roller C(8) are perpendicular to and coplanar with the axes of roller B(4) and roller D(16), and the vertical direction of the shuttle is controlled by rollers B(4) and D(16). Constraints, the radial direction is constrained by rollers A(2) and C(8).

[0025] The roller B (4) is located on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com