Clamping type broken bridge connecting piece

A technology for connectors and broken bridges, which is applied in the field of clip-type broken bridge connectors, can solve problems such as difficulty in ensuring the vertical connection consistency of light steel keels, affecting wall construction efficiency and quality, and troublesome operation, so as to improve construction efficiency and quality, ensure installation consistency, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

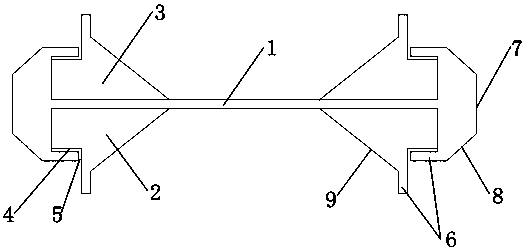

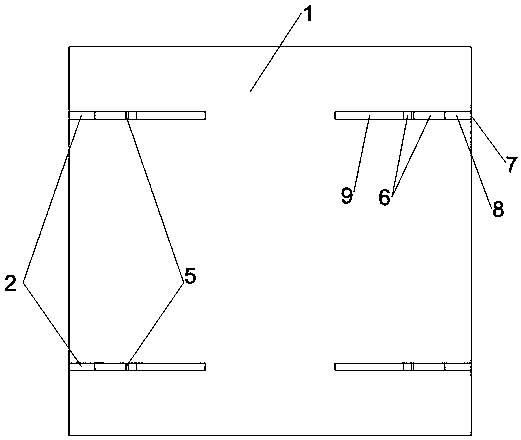

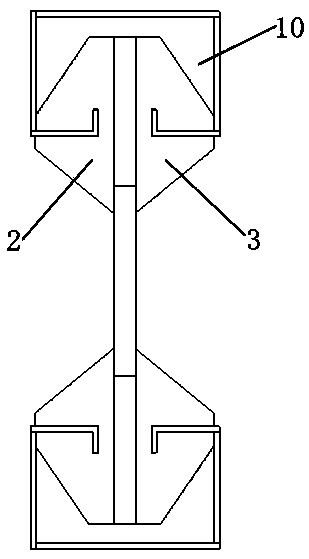

[0011] A snap-type broken bridge connector of the present invention such as figure 1 , figure 2 As shown, a vertical board 1 is provided, the left sides of the front and rear ends of the vertical board 1 are connected with the upper and lower rows of left horizontal boards 2, and the right sides of the front and rear ends of the vertical board 1 are connected with the upper and lower rows of right horizontal boards 3 , the left horizontal plate 2 and the right horizontal plate 3 are symmetrically arranged, and the connecting jacks are arranged symmetrically on the left horizontal plate 2 and the right horizontal plate 3. The shape of the connecting jacks should match the structure of the open end of the light steel keel. figure 1 Shown is the structure used for C-shaped steel clip-type broken bridge connectors. The connecting jacks are vertical strip holes 4 and horizontal strip holes 5 that are perpendicular to each other. The center line of the vertical strip holes 4 is par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com