Oil paper insulation micro-water content evaluation method utilizing mixed polarization model parameters

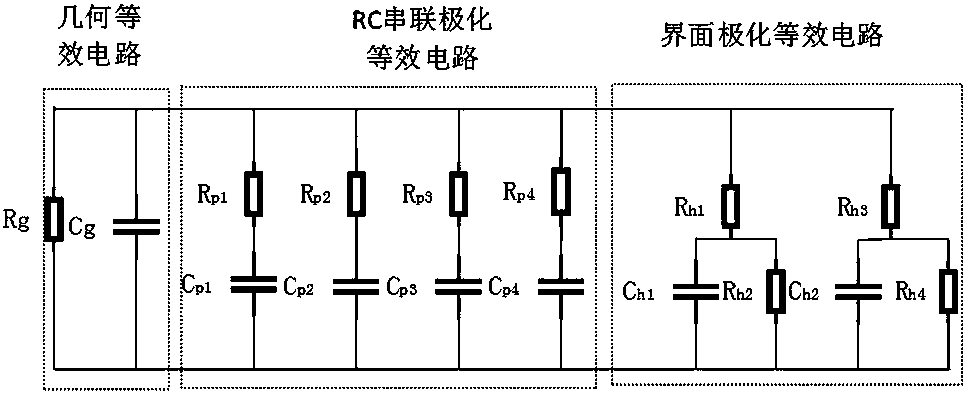

A technology of oil-paper insulation and mixed polarization, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc., can solve the problems of complex polarization response process of the internal medium and cannot accurately and truly reflect the medium response process of the oil-paper insulation system. The effect of simplicity, high accuracy, and high degree of parameter fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

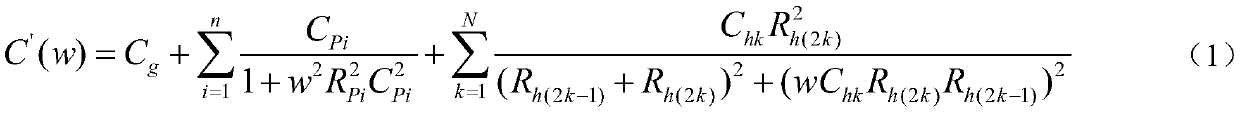

Method used

Image

Examples

Embodiment 1

[0048] According to step S1, three groups of oil-paper insulation test samples with micro-moisture content of 0.244%, 1.58% and 3.63% were produced, and the frequency-domain dielectric data of these three groups were tested by DIRANA dielectric response analyzer, as shown in Table 1-Table 3 Show:

[0049] Table 1 Dielectric measured data in frequency domain with 0.244% micro-water content

[0050]

[0051] Table 2 Dielectric measured data in frequency domain with micro-water content of 1.58%

[0052]

[0053]

[0054] Table 3 Micro water content 3.63% frequency domain dielectric measured data

[0055]

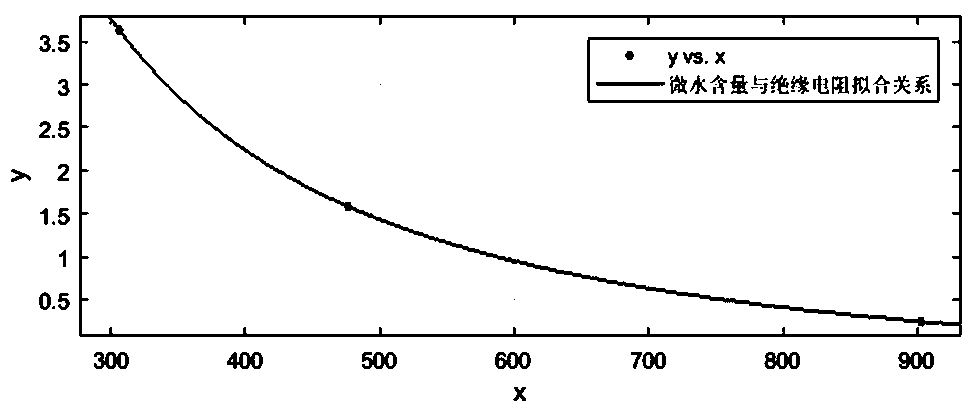

[0056] Based on the test data in Table 1-Table 3, according to steps S2 and S3, three groups of insulation resistance R with different water contents are solved g value, as shown in Table 4:

[0057] Table 4 Insulation resistance value of different moisture content

[0058] Moisture content (%) R / GΩ 0.244 R g =902.5029

1.58 R g =476.7843 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com