Sound box structure

A sound box and integrated technology, applied in the field of sound box application, can solve the problems of high cost, manual screwing, low production efficiency, etc., and achieve the effect of reducing material cost, improving assembly efficiency, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

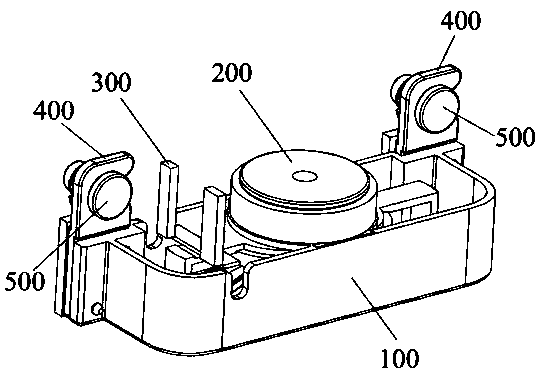

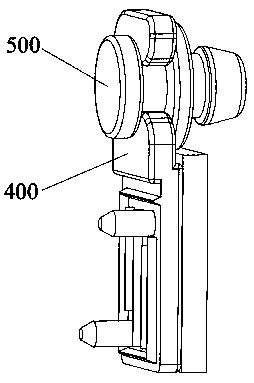

[0028] like figure 1 As shown, this embodiment provides a sound box structure, including a sound box main body 100, a magnetic core 200, an electronic wire connector 300, a sound box hanging ear 400, and a silicone structure 500; middle position, and the magnetic core 200 is fixedly connected with the speaker body 100 by screws; The connection is fixed by screws; the electronic wire connector 300 is set upwards and can be used for assembling the sound signal wires connected from the main board of the TV set.

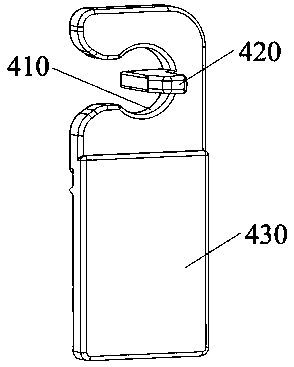

[0029] In this embodiment, the number of the speaker mounting ears 400 includes at least two, and the two speaker mounting ears 400 are respectively arranged on the two sides of the speaker body 100, and are respectively connected to the speaker body 100 through screws. Fixed connection; on each of the speaker hanging ears 400, there is a silicone structure 500, and the silicone structure 500 can be used to fix the speaker main body 100 on the middle shell of the TV.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com