Nozzle for fire fighting of lithium battery box and lithium battery with fireproof function

A lithium battery and nozzle technology, applied to small-sized batteries/battery packs, large-sized batteries/battery packs, battery pack components, etc., can solve the problems of automatic release of fire extinguishing agents, etc., to avoid fires and protect The effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

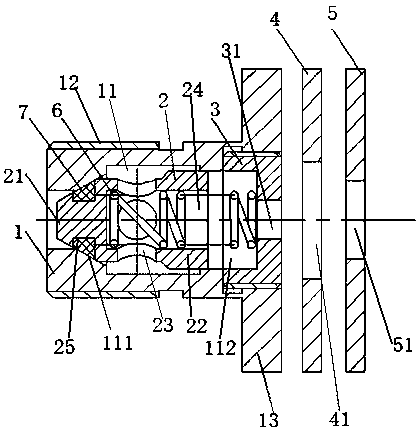

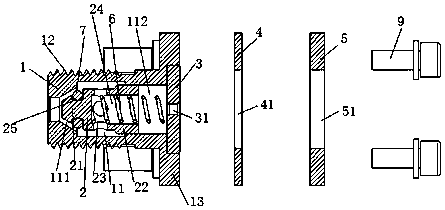

[0032] Please refer to figure 1 , The present embodiment provides a nozzle for fire protection of a lithium battery box, the nozzle includes a nozzle body 1 and a nozzle core 2, the nozzle core 2 is arranged in the nozzle body 1, and also includes an elastic member 6 and a nozzle orifice plate 3. Wherein, a first flow channel 11 is formed inside the nozzle body 1, and the first end of the nozzle body 1 is used to connect with the pipeline, so that the first end of the first flow channel 11 communicates with the pipeline for transporting the fire extinguishing agent, and the other end of the pipeline is connected to the fire extinguishing pipe. The agent storage tank is connected; the second end of the nozzle body 1 is sealed with the nozzle orifice 3, and the nozzle orifice 3 is provided with at least one spray hole 41 for spraying the fire extinguishing agent flowing out from the second end of the first flow channel 11, Extinguish lithium batteries.

[0033] Among them, such...

Embodiment 2

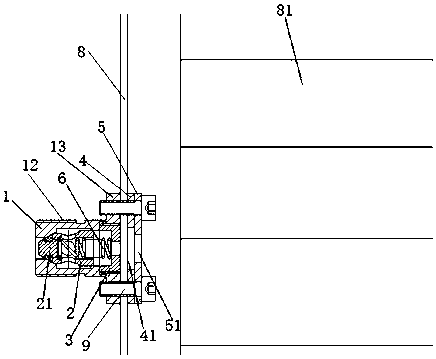

[0044] Such as figure 2 , on the basis of Embodiment 1, this embodiment provides a lithium battery with a fireproof function, the lithium battery includes a battery body, the battery body includes a battery box 8 and a cell 81 installed in the battery box 8, and Including the nozzle as described in Embodiment 1, one end of the nozzle body 1 of the nozzle is provided with a fixed ear 13, and the fixed ear 13 is provided with 4 mounting holes, and the side wall of the battery box 8 is correspondingly provided with 4 mounting holes, The mounting hole is provided with a connecting piece 9 for fixedly connecting the fixing ear 13 of the nozzle body 1 with the battery case 8 , and then fixing the nozzle on the battery case 8 .

[0045] Wherein, the inner wall of the battery case 8 is provided with a flange 5, and the connector 9 is used to fixedly connect the flange 5, the battery case 8 and the nozzle orifice 3, and the connection between the nozzle orifice 3 and the battery case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com