High-precision wear resistant steel ball efficient screening device and operation method thereof

A screening device and high-precision technology, applied in chemical instruments and methods, solid separation, classification, etc., can solve problems such as high-precision wear-resistant steel balls are easy to block, poor stability, high-precision steel ball damage, etc., to reduce Impact force, ease of collection, and integrity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

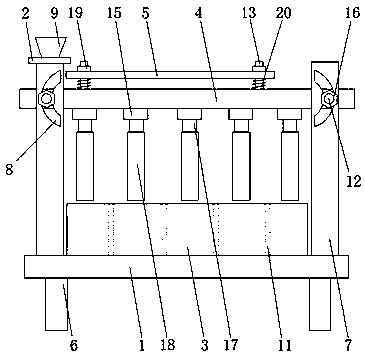

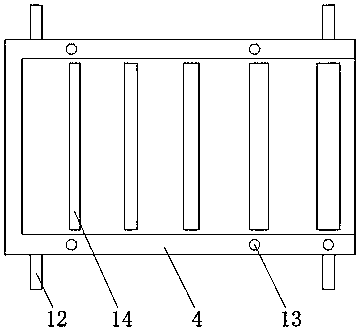

[0028] as attached Figure 1-4 Shown: a high-precision wear-resistant steel ball high-efficiency screening device, including a base plate 1, a fixed plate 2, a material box 3, a fixed frame 4 and a baffle plate 5, characterized in that: the base plate 1 is set on a bracket 6, Base plate 1 is provided with vertical plate 7, and limit groove 8 is offered on vertical plate 7, and base plate 1 is connected with support 6, vertical plate 7 by welding, has improved the distance between base plate 1 and support 6, vertical plate 7 The connection strength enhances the structural strength of the screening device and improves the stability of high-precision wear-resistant steel balls during the screening process. The fixed plate 2 is arranged on the top of the vertical plate 7, and a feed bin 9 is arranged on the vertical plate 7. And at the bottom of the feeding bin 9, a drop pipe 10 is arranged, and the fixed plate 2 and the vertical plate 7 are connected by welding to improve the con...

Embodiment 2

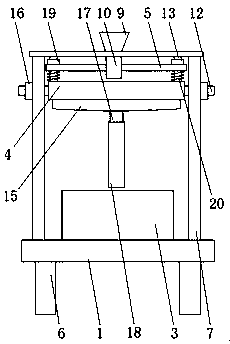

[0040] as attached Figure 5-8 As shown, a high-precision wear-resistant steel ball high-efficiency screening device includes a base plate 1, a fixed plate 2, a material box 3, a fixed frame 4 and a baffle plate 5, and is characterized in that: the base plate 1 is arranged on a support 6, Base plate 1 is provided with vertical plate 7, and limit groove 8 is offered on vertical plate 7, and base plate 1 is connected with support 6, vertical plate 7 by welding, has improved the distance between base plate 1 and support 6, vertical plate 7 The connection strength enhances the structural strength of the screening device and improves the stability of high-precision wear-resistant steel balls during the screening process. The fixed plate 2 is arranged on the top of the vertical plate 7, and a feed bin 9 is arranged on the vertical plate 7. And at the bottom of the feeding bin 9, a drop pipe 10 is arranged, and the fixed plate 2 and the vertical plate 7 are connected by welding to im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com