Aluminum-wood sectional material assembling device and method thereof

A technology for assembling equipment and aluminum profiles, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as inability to assemble building materials, achieve the effects of increasing efficiency, increasing support strength, and ensuring assembly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

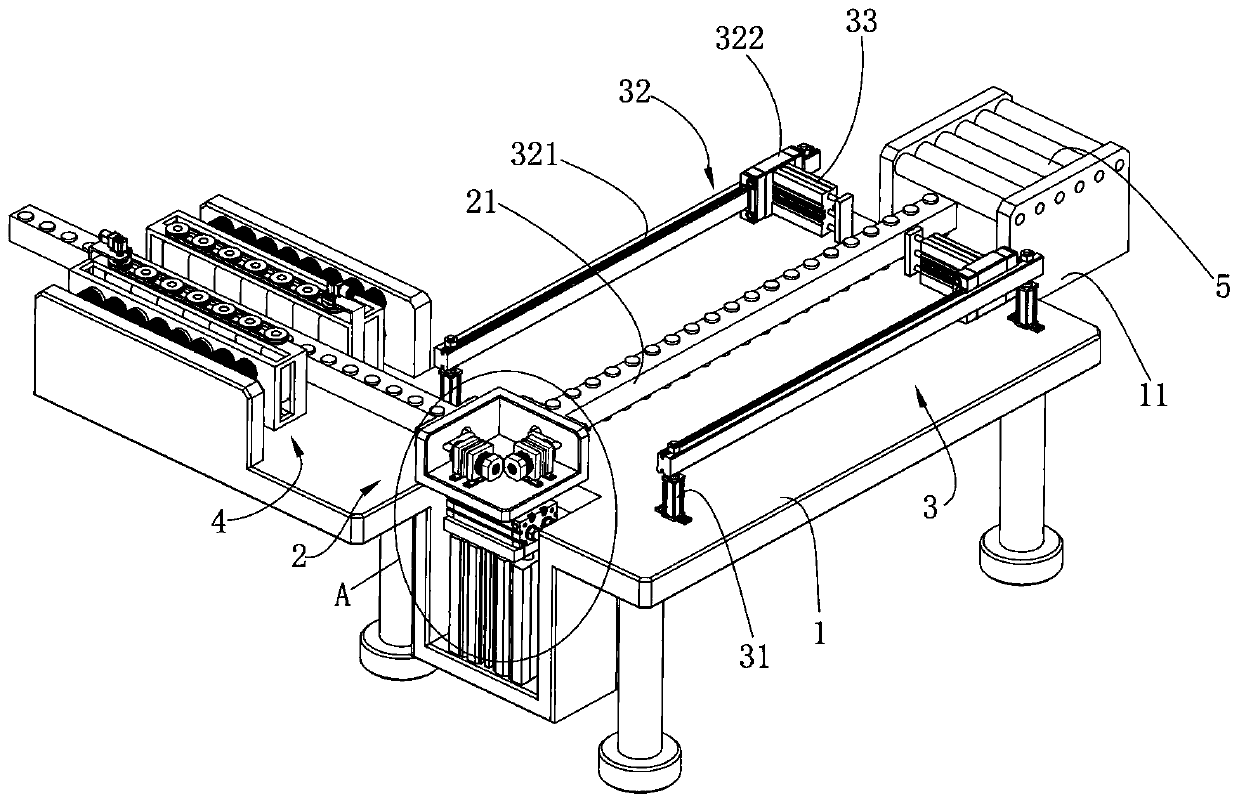

[0032] see Figure 1 to Figure 4 , the present invention provides a technical solution:

[0033] An aluminum wood profile assembly equipment, including a frame 1, an aluminum material fixing mechanism 2, a wood assembly mechanism 3, a discharge mechanism 4 and a rotating roller 5, wherein:

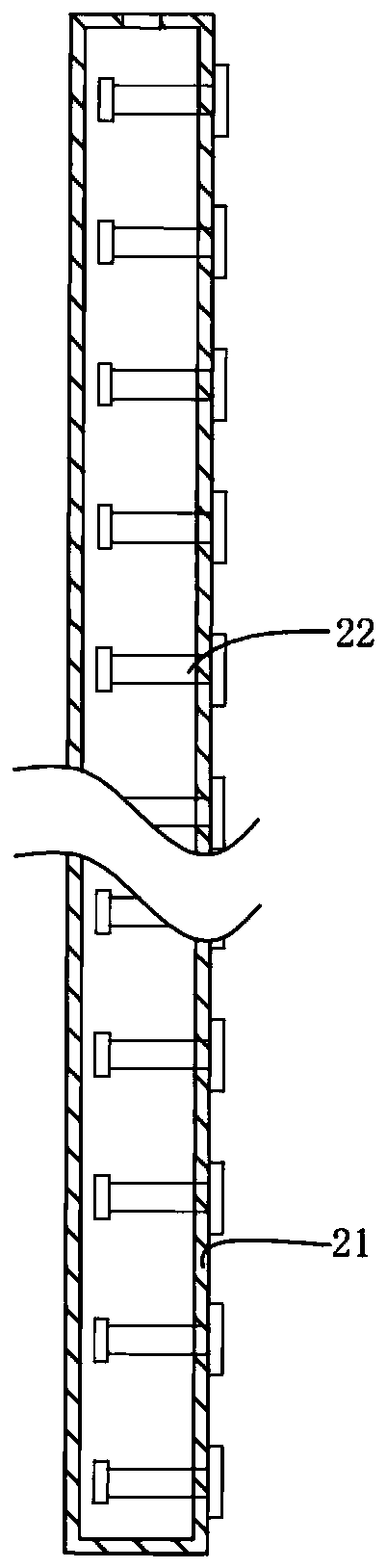

[0034] The frame 1 is provided with a bracket 11, and the two ends of several rotating rollers 5 are installed on the bracket 11 through bearing rotation respectively, wherein the rotating rollers 5 are used to support the wooden profile;

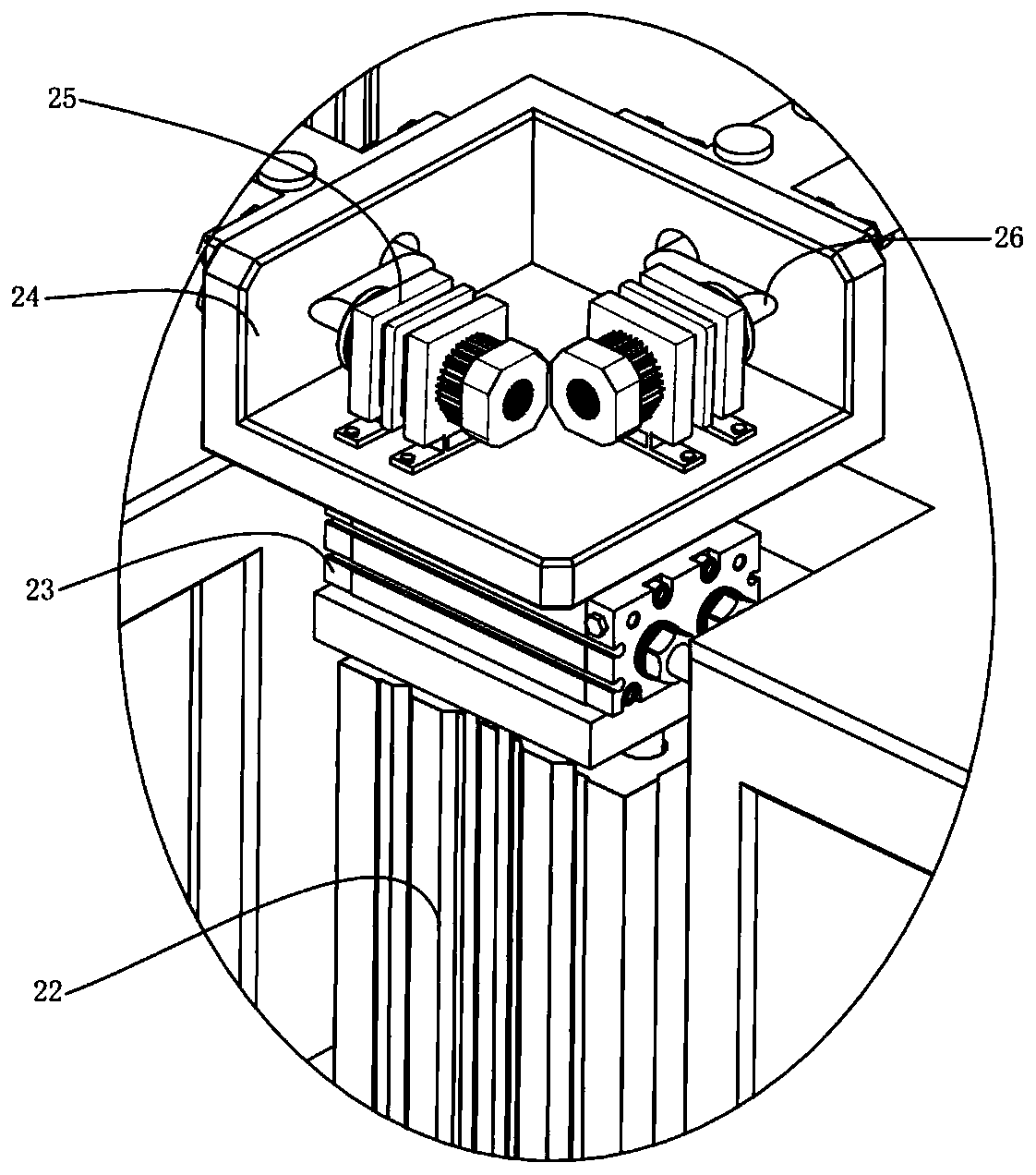

[0035] The aluminum fixing mechanism 2 includes a hollow support rod 21, a biaxial hydraulic cylinder 22, a rotary cylinder 23, a support frame 24, a high-pressure air pump 25 and an air pipe 26. The biaxial hydraulic cylinder 22 is fixed on the frame 1 by bolts, and the biaxial hydraulic cylinder The power output end of the cylinder 22 is fixedly installed with a rotary cylinder 23 by bolts, and the support frame 24 is fixedly installed on the power o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com