Double-layer bulletproof air inlet grille, air inlet grille assembly and automobile

A technology of air intake grille and grille, which is applied in the direction of component optimization, vehicle parts, vehicle safety arrangement, etc. It can solve problems such as bulletproof failure, difficult operation, and blade angle cannot be adjusted freely, so as to ensure safety and automatically control tilt Angle, the effect of preventing secondary ricochets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

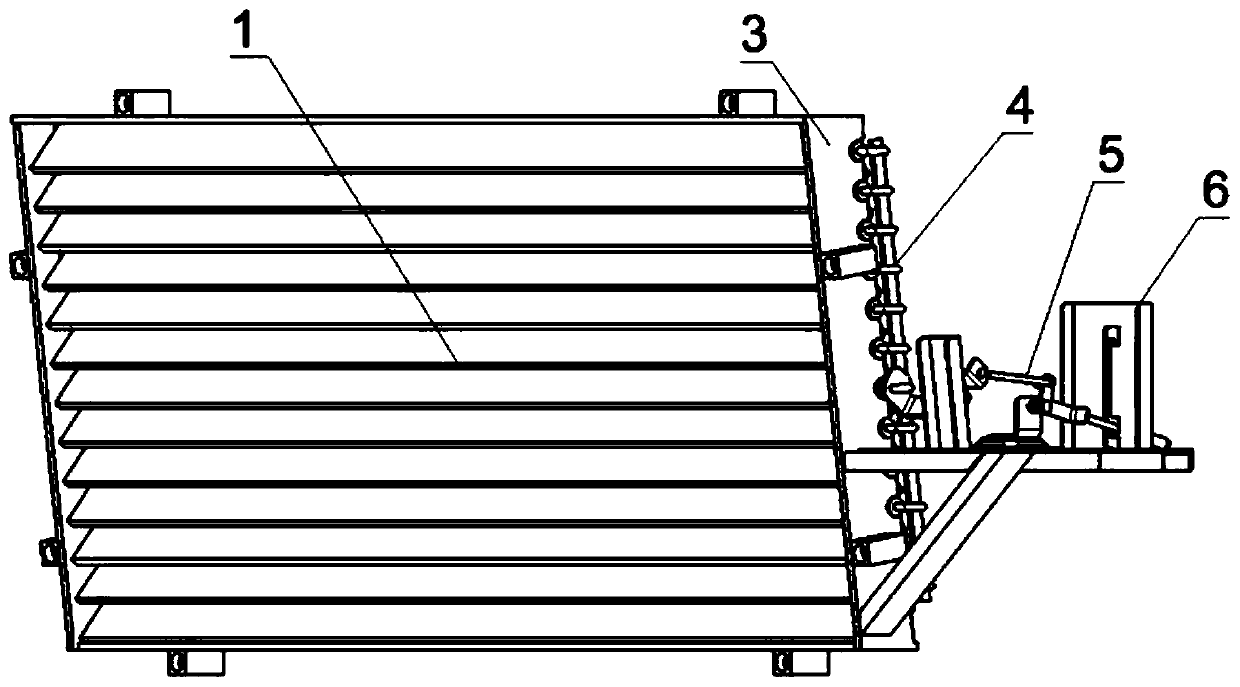

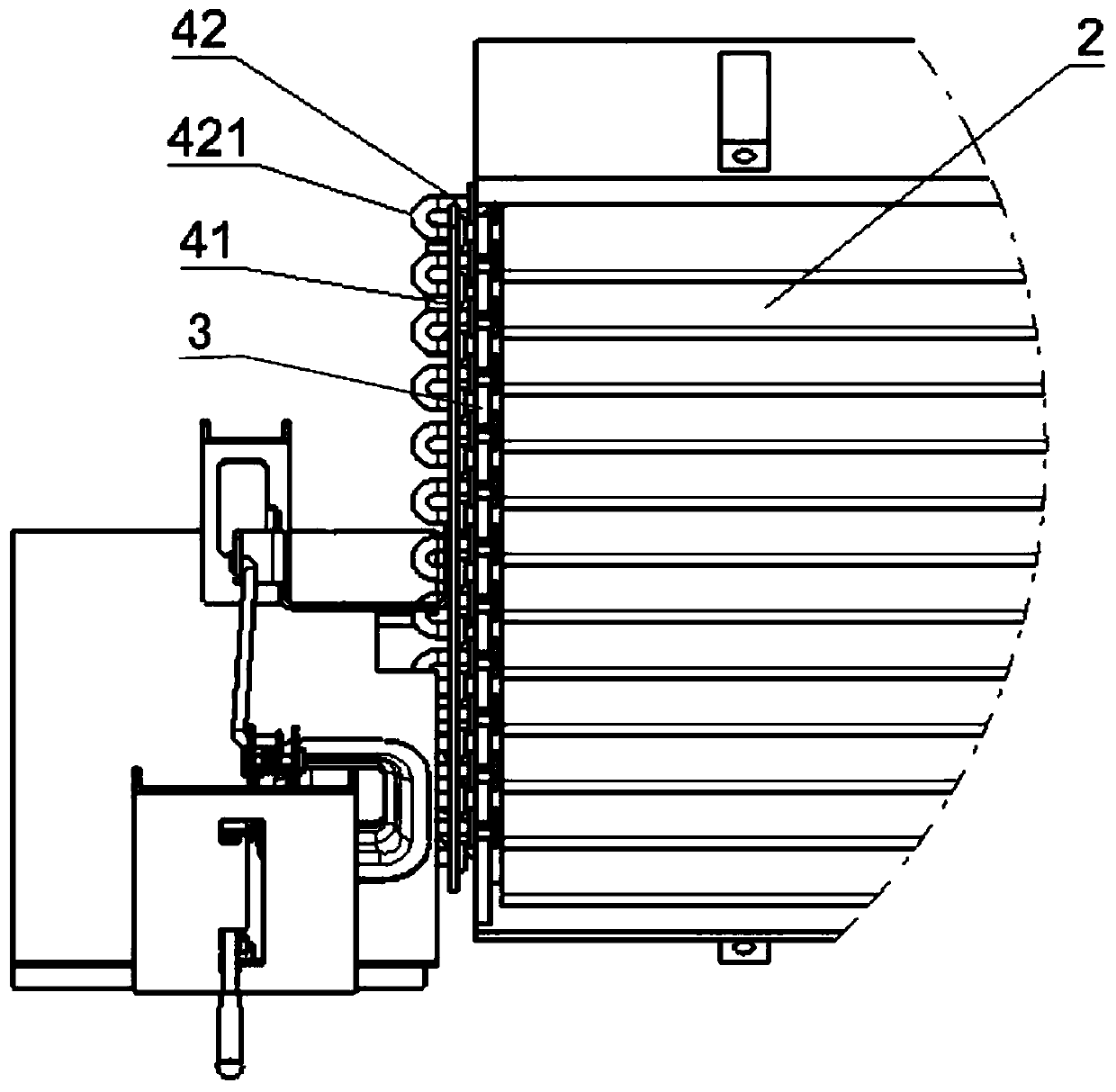

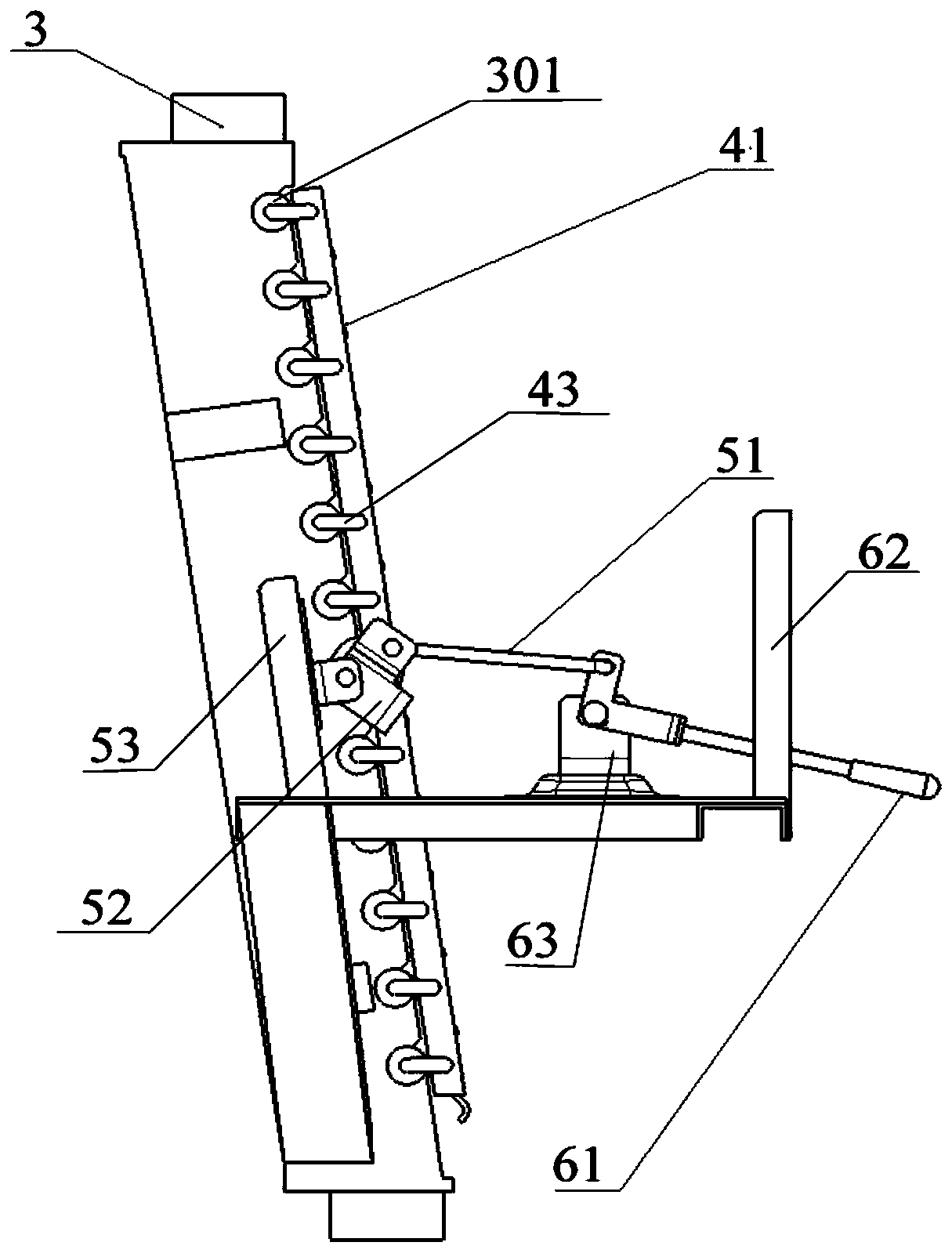

[0025] Such as Figure 1-7 As shown, a double-layer bulletproof air intake grille includes an outer frame 3 located at the air inlet of the front cover, the front end of the outer frame 3 is fixedly connected with a fixed grille 1 with a fixed blade inclination angle, and the rear end of the outer frame 3 is connected with a The movable grille 2 with adjustable blade inclination angle, the two sides of the blades of the movable grille 2 are fixedly provided with the linkage mechanism 4 which can make the blades of the movable grille 2 rotate relative to the outer frame 3 together.

[0026] In the above technical solution, the linkage mechanism 4 includes shafts 42 fixedly arranged on both sides of the movable grille 2, the shafts 42 pass through the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com