Push-pull type vehicle operating equipment for tramcar to go in and out of tank

A tank push-pull type, mine car technology, applied in the direction of lifting equipment, transportation and packaging in mines, can solve the problems of inability to realize the tank feeding cart, long push-pull claw structure, complicated operation and use, etc., to save on-site space, Simple structure, convenient construction and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

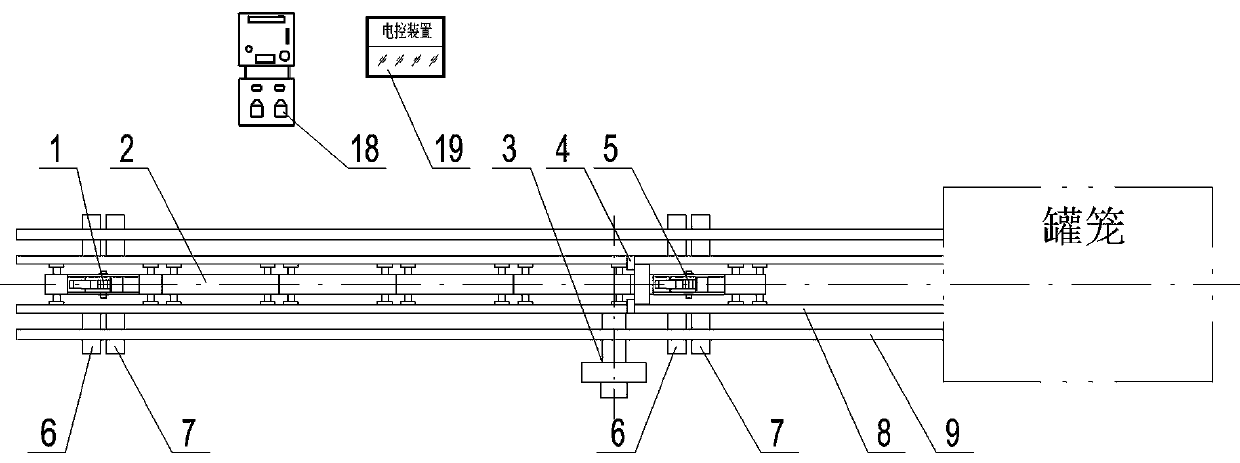

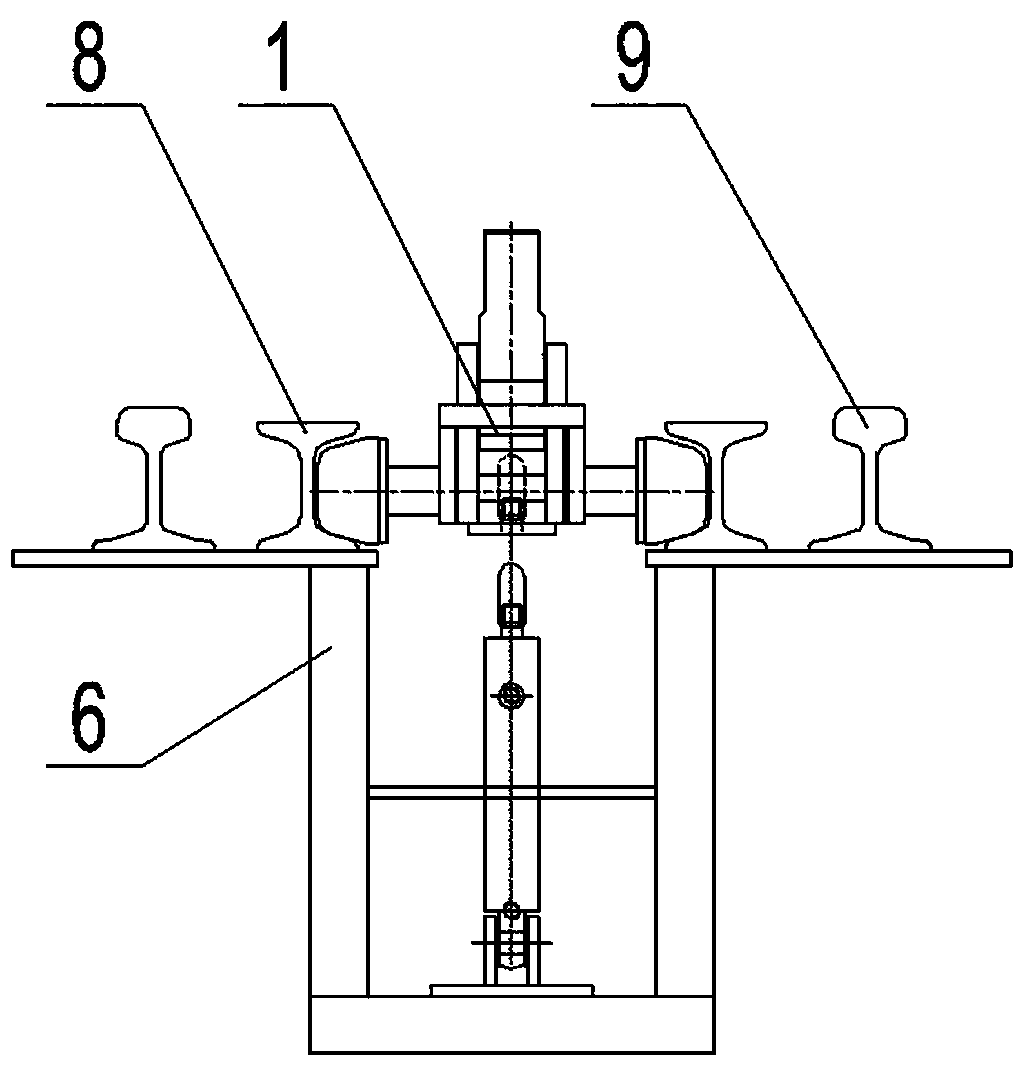

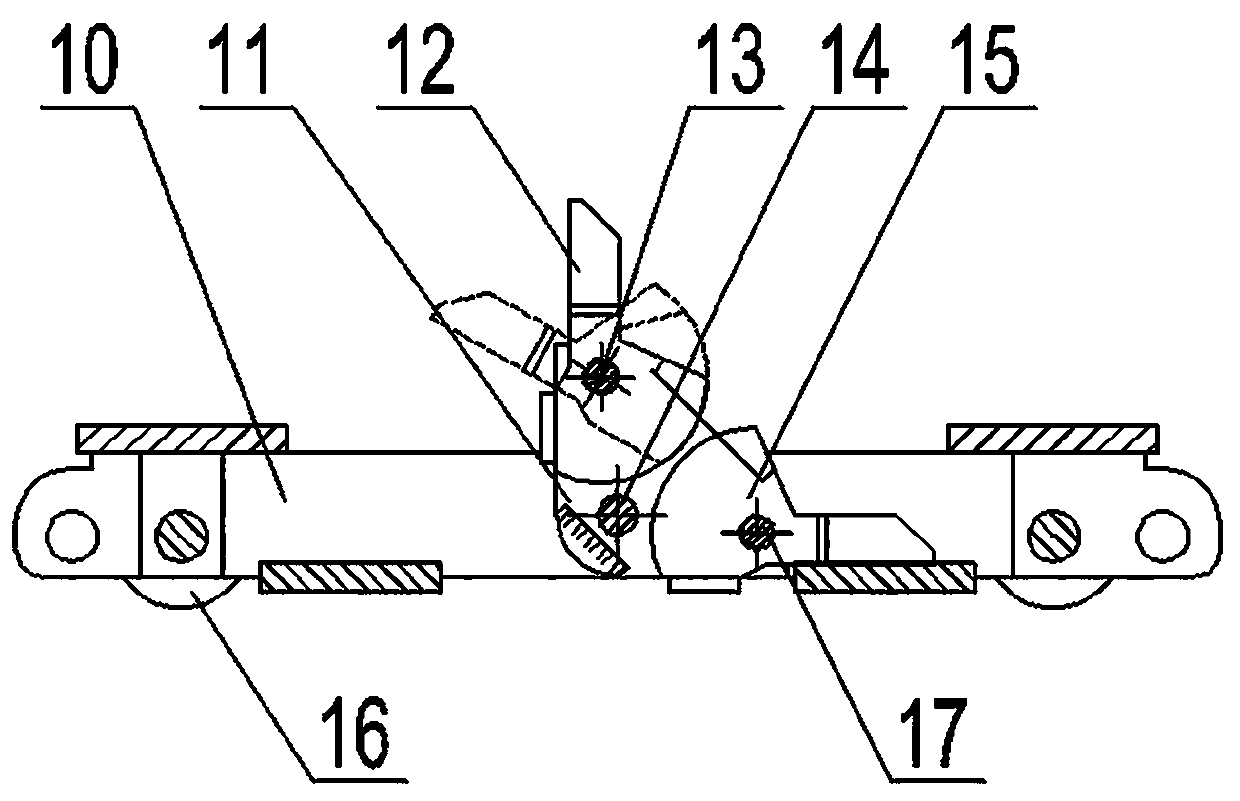

[0032] Mine car into the tank push-pull operating equipment, such as figure 1 , figure 2 and image 3 As shown, it includes a rear push-pull trolley 1, a connecting trolley 2, a transmission device 3, a front push-pull trolley 5, a claw lifting device 6, a pushing claw lifting device 7 and a trolley running track 8; it also includes a power output device 18, an intelligent electric control device 19; the rear push-pull trolley 1, the connecting trolley 2 and the front push-pull trolley 5 are connected to each other in turn, and all move back and forth along the trolley running track 8, the rear push-pull trolley 1 is far away from one end of the cage, and the front push-pull trolley 5 is close to one end of the cage;

[0033] The transmission device 3 is fixed on the rail support beam, and the backward push-pull trolley 1 and the front push-pull tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com