A hydrogel sensing membrane capable of sequentially detecting anions, metal cations and dye molecules and its preparation method

A metal cation, sequential detection technology, applied in the direction of material analysis, material analysis, measurement device using sonic/ultrasonic/infrasonic waves, and can solve problems such as no discovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

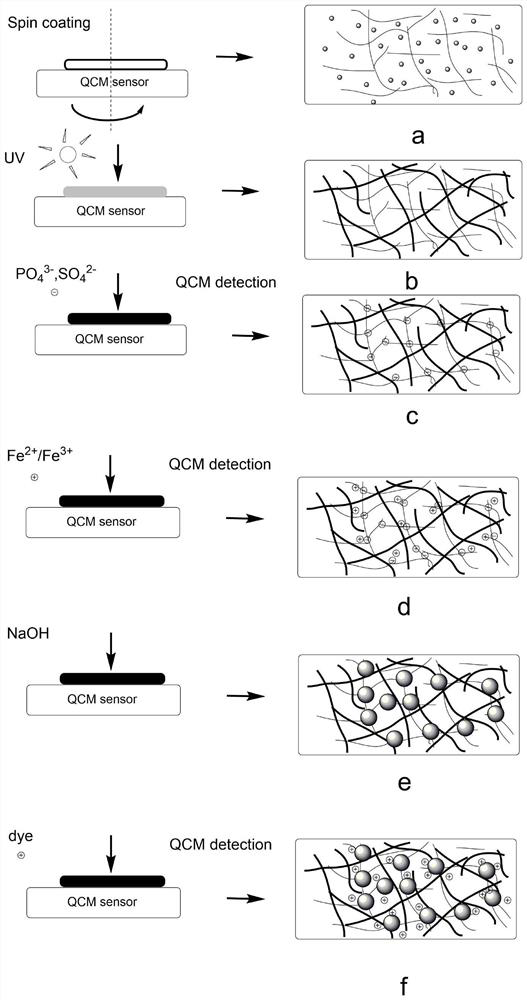

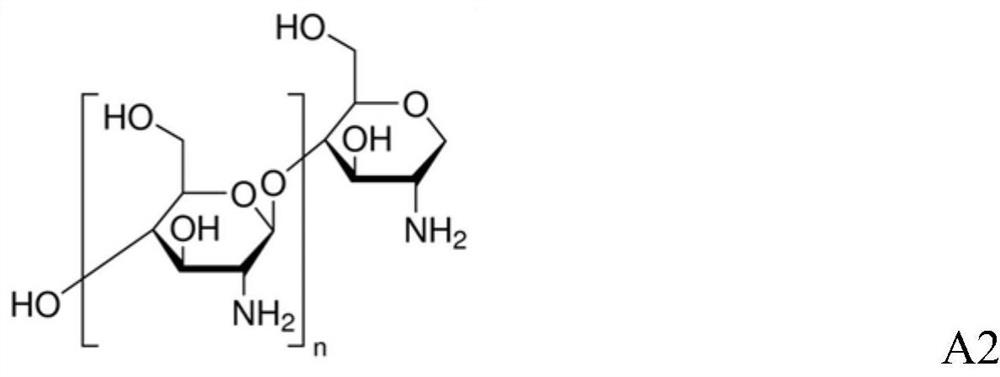

[0036] (1) Organic monomer acrylamide (60wt%), photoinitiator Irgacure 2959 (1.0mol% of organic monomer), crosslinking agent N, N'-methylenebisacrylamide (0.03mol of organic monomer %) and the molecular weight of water-soluble short-chain chitosan is 5KDa, deacetylation degree 85% (40wt%) joins in the water of 15mL, forms transparent solution under heating and stirring at 60 ℃ then, blows nitrogen gas deoxygenation 5 minutes then through uniform The glue machine spin-coated the surface of the gold-plated electrode on the quartz wafer to form a film (the homogenization time was 30 seconds, and the rotation speed was 2000rpm), and then irradiated with ultraviolet light (150W) for 20 minutes to form a polyacrylamide / chitosan composite hydrogel.

[0037] (2) Then, the quartz wafer of the spin-coated polyacrylamide / chitosan composite hydrogel film is connected to the flow cell of the quartz crystal microbalance, and the sodium phosphate solution is passed through the quartz wafer su...

Embodiment 2

[0042] (1) organic monomer methacrylamide and N,N-dimethylacrylamide (61wt%), photoinitiator Irgacure 2959 (1.2mol% of monomer), crosslinking agent glutaraldehyde (monomer 0.035mol%) and water-soluble short-chain chitosan with a molecular weight of 10KDa and a deacetylation degree of 86% (39wt%) were added to 15mL of water, and then heated and stirred at 65°C to form a transparent solution, followed by nitrogen gas deoxygenation for 5 minutes Spin coating on different substrates such as quartz wafer gold-plated electrodes, silicon chips or mica sheets through a homogenizer to form a film (the homogenization time is 40 seconds, the rotation speed is 2500rpm), and then irradiated with ultraviolet light (150W) for 30 minutes to form poly(formazan Acrylamide-co-N,N-dimethylacrylamide) / chitosan composite hydrogel.

[0043] (2) Then, the quartz wafer spin-coated with poly(methacrylamide-co-N,N-dimethylacrylamide) / chitosan composite hydrogel film was connected to the flow cell of the...

Embodiment 3

[0048] (1) organic monomer N-tert-butylacrylamide (62wt%), photoinitiator Irgacure 2959 (1.4mol% of monomer), crosslinking agent ethylene glycol dimethacrylate (0.04mol% of monomer) %) and the molecular weight of water-soluble short-chain chitosan is 12KDa, deacetylation degree 87% (38wt%) joins in the water of 15mL, forms transparent solution under heating and stirring at 60 ℃ then, blows nitrogen to deoxygenate 5 minutes then through uniform The glue machine spin-coats the surface of different substrates such as quartz wafer gold-plated electrodes, silicon wafers or mica sheets to form a film (uniform glue time 50 seconds, speed 3000rpm), and then irradiates with ultraviolet light (150W) for 30 minutes to form poly N-tert-butyl acrylamide / chitosan composite hydrogel.

[0049] (2) Then, the quartz wafer of spin-coating polyN-tert-butylacrylamide / chitosan composite hydrogel film is connected to the flow cell of quartz crystal microbalance, sodium nitrate solution is passed thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com