Preparation method of molybdenum sulfide complex and its application in detecting hexavalent chromium in water

A compound, molybdenum sulfide technology, applied in the field of environmental detection, achieves the effects of low cost, high sensitivity and improved catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

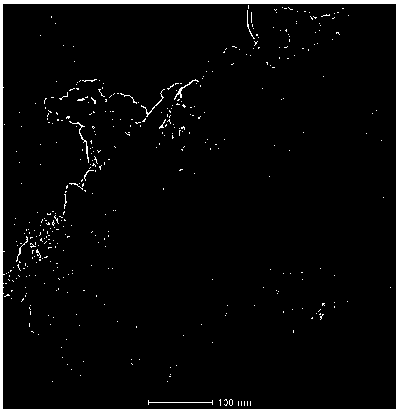

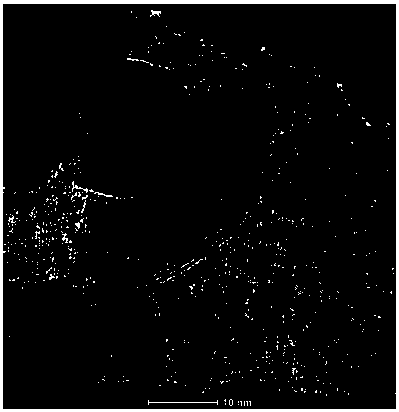

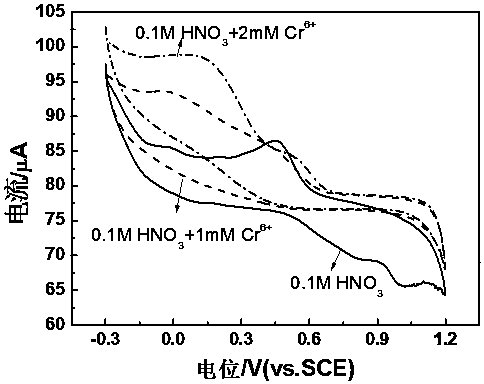

Image

Examples

1 example 1

[0040] 1. At room temperature, weigh ferric chloride hexahydrate and ferrous chloride tetrahydrate and dissolve them in deionized water, stir in nitrogen for 20 minutes to obtain solution 1; the rate of feeding nitrogen is 100-200 ml / min.

[0041] 2. Keep the ratio of the amount of the two solutes in solution 1 as 1 / 3.

[0042] 3. Continue to feed nitrogen, heat the solution in a water bath from 1 to 60°C and keep it for 5 minutes; the rate of feeding nitrogen is 100-200 ml / min.

[0043] 4. Under the protection of nitrogen, slowly add ammonia water with a concentration of 1.5 mol / L to solution 1 until the pH is 7.5; the rate of feeding nitrogen is 100-200 ml / min.

[0044] 5. Then aging the above mixed solution at 70°C for 20-40 minutes.

[0045] 6. After the reaction, magnetically separate to obtain ferric oxide, and wash the obtained ferric oxide with deionized water for 5 times until the pH of the solution is within the range of 7.0.

[0046] 7. Transfer the separated iron...

2 example 2

[0058] 1. At room temperature, weigh ferric chloride hexahydrate and ferrous chloride tetrahydrate, dissolve them in deionized water, and stir in nitrogen for 20 minutes to obtain solution 1; the rate of feeding nitrogen is 100-200 ml / min.

[0059] 2. Keep the ratio of the amount of the two solutes in solution 1 as 1 / 4.

[0060] 3. Continue to feed nitrogen, heat the solution in a water bath from 1 to 60°C and keep it for 10 minutes; the rate of feeding nitrogen is 100-200 ml / min.

[0061] 4. Under the protection of nitrogen, slowly add ammonia water with a concentration of 1.5 mol / L to solution 1 until the pH is 7.5; the rate of feeding nitrogen is 100-200 ml / min.

[0062] 5. Then aging the above mixed solution at 60° C. for 30 minutes.

[0063] 6. After the reaction, magnetically separate to obtain ferric oxide, and wash the obtained ferric oxide with deionized water 8 times until the pH of the solution is within the range of 7.0.

[0064] 7. Transfer the separated iron fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com