A coaxial heterostructured sno 2 Preparation method and application of /zno nanocomposite fiber material

A nanocomposite fiber and heterogeneous structure technology, which is applied in fiber processing, textile and papermaking, and hollow filament manufacturing, can solve the problems of poor dispersion, complicated preparation methods, and high raw material costs, and overcome the limited application, Sensitive performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

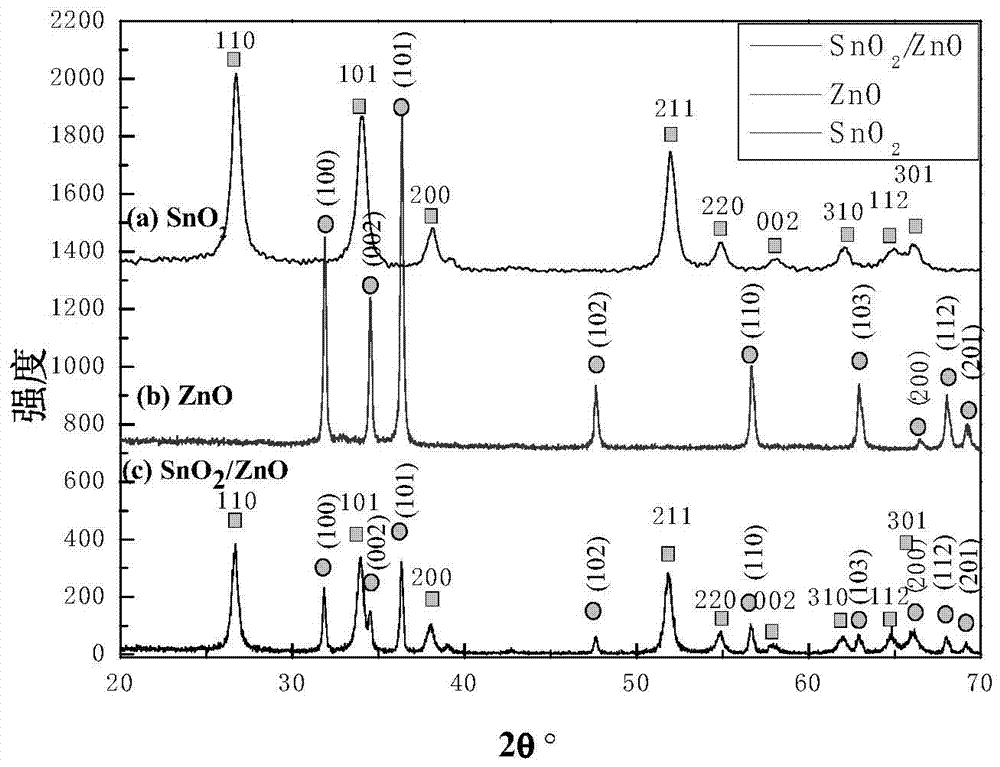

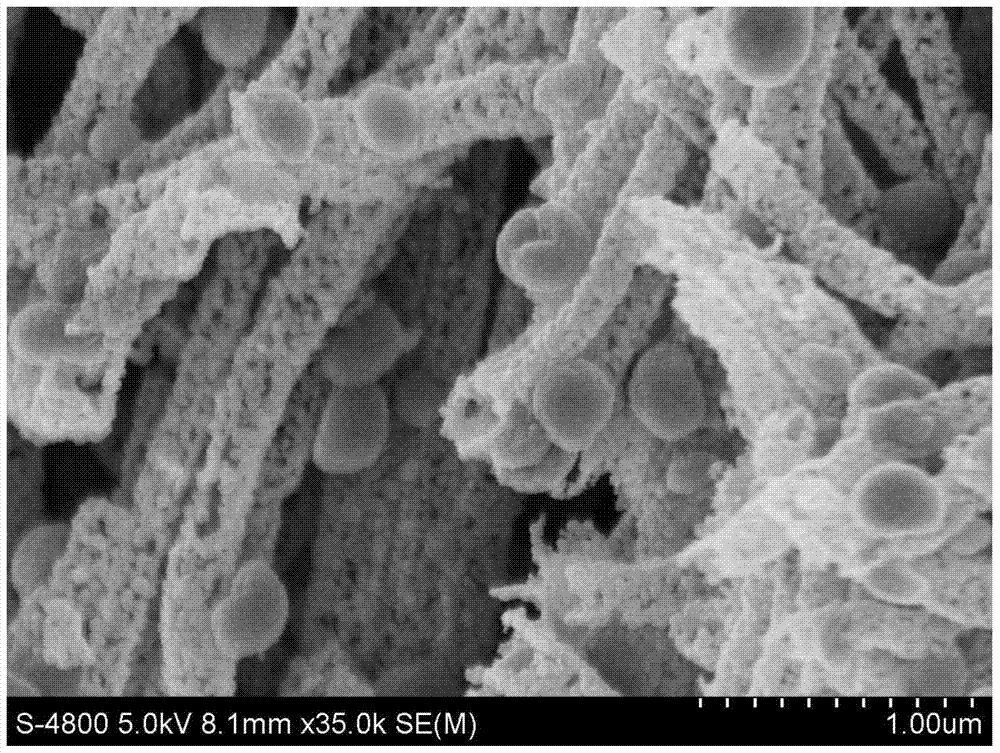

[0028] Two-step method to prepare SnO with coaxial heterostructure 2 / ZnO Nanocomposite

[0029] A coaxial heterostructure of SnO 2 The preparation method of / ZnO composite nanofiber material comprises the following processing steps:

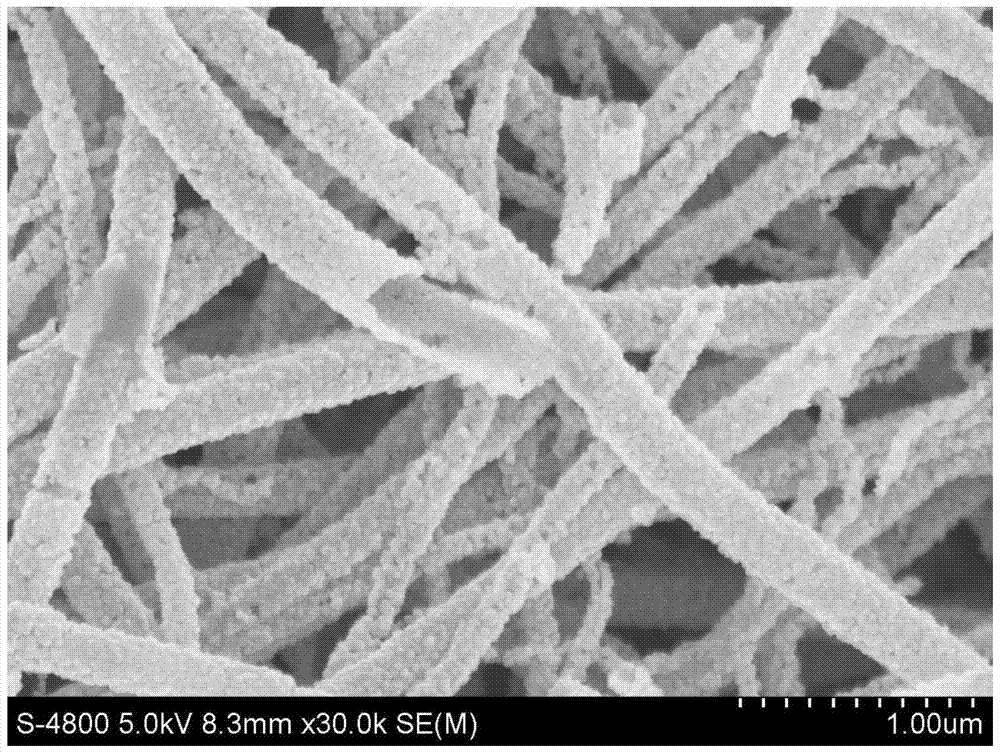

[0030] ① Weigh 0.5g SnCl 2 2H 2 Dissolve O in 4ml of absolute ethanol, stir magnetically until completely dissolved, the solution is colorless and transparent, weigh 0.8g of PVP and 2ml of DMF, dissolve it in SnCl 2 In the ethanol solution, after magnetic stirring for 8 hours, a colorless, transparent and viscous spinning precursor solution was formed. The prepared SnO 2 The spinning precursor solution was injected into a 10ml glass needle tube connected with a No. 7 needle, and connected to the electrospinning device. The electrospinning device is mainly composed of three parts: a high-voltage power supply, a container with a nozzle and a receiving device. The container with the nozzle is composed of a 10ml glass needle tube connected wit...

Embodiment 2

[0033] ①Weigh 1.1g SnCl 2 2H 2 O was dissolved in 1.5ml of absolute ethanol, magnetically stirred until completely dissolved, the solution was colorless and transparent, weighed 1.5g of PVP and 1.2ml of DMF, dissolved in SnCl 2 In the ethanol solution, after magnetic stirring for 8 hours, a colorless, transparent and viscous spinning precursor solution was formed, and the electrospinning method was used to obtain the SnCl-containing 2 The white paper-like intermediate product is calcined with oxygen at a high temperature of 600°C to obtain SnO with a hollow multi-level structure 2 Nanofibers;

[0034] ②SnO 2 Make nanofibers into a paste, spin-coat on a glass slide with a thickness of 0.1-0.5 mm, dry in a drying oven at 250 °C for 1.5 hours, and drop 0.06 mol / L zinc acetate solution evenly on the SnO 2 Place the dried glass slide in a 0.06mol / L ethanol solution of zinc acetate, heat it in a constant temperature water bath at 90°C for 4 hours, and finally take out the glass ...

Embodiment 3

[0036] ①Weigh 0.8g SnCl 2 2H 2 Dissolve O in 8ml of absolute ethanol, stir magnetically until completely dissolved, the solution is colorless and transparent, weigh 1g of PVP and 4.8ml of DMF, and dissolve it in SnCl 2 In the ethanol solution, after magnetic stirring for 8 hours, a colorless, transparent and viscous spinning precursor solution was formed, and the electrospinning method was used to obtain the SnCl-containing 2 The white paper-like intermediate product is calcined with oxygen at a high temperature of 600°C to obtain SnO with a hollow multi-level structure 2 Nanofibers;

[0037] ②SnO 2 The nanofibers were made into a paste, spin-coated on a glass slide with a thickness of 0.5 mm, and dried in a drying oven at 200 ° C for 1 hour, and 0.02 mol / L zinc acetate solution was evenly dropped on the SnO 2 On the surface of the fiber, dry in a drying oven at 200°C for 30 minutes; put the dried glass slide in a 0.02mol / L ethanol solution of zinc acetate, heat it in a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com