A heavy duty loom

A ribbon loom, heavy-duty technology, applied in the field of textile ribbons, can solve problems such as yarn collapse, reduce ribbon efficiency, and affect ribbon progress, and achieve high efficiency and fast thread passing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

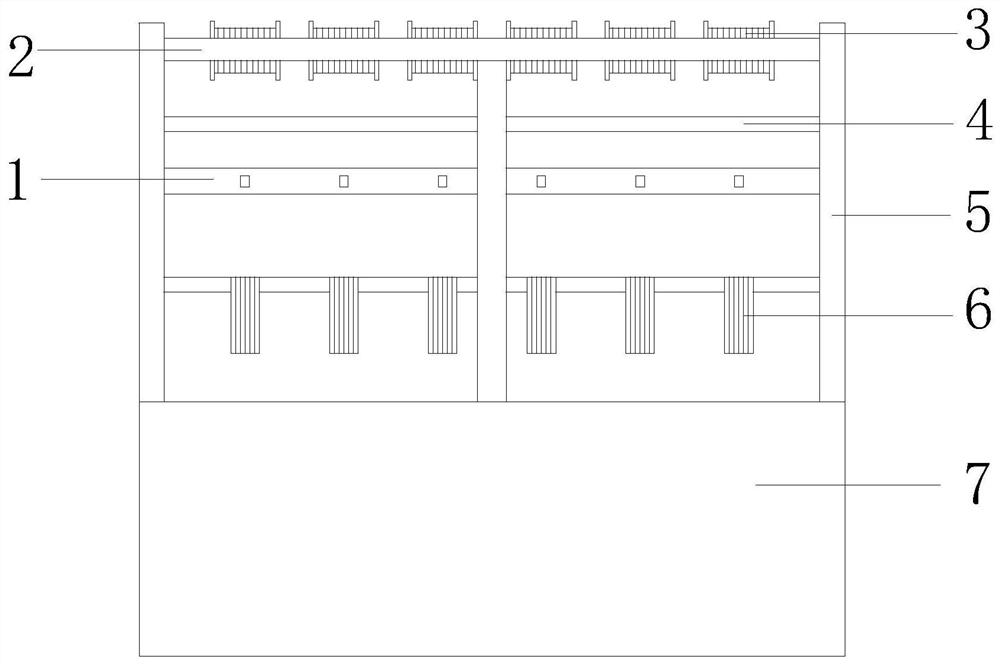

[0034] see Figure 1-10 , the present invention provides a technical solution for a heavy-duty ribbon loom: its structure includes a thread passing device 1, a yarn bobbin holder 2, a yarn bobbin 3, a static removal guide roller 4, a support frame 5, a yarn tension adjustment device 6, and a ribbon loom Body 7, one side of the loom body 7 is mechanically connected with a support frame 5, and the support frame 5 is sequentially installed with a yarn tension adjustment device 6, a thread passing device 1, and a static electricity removal guide roller in a direction away from the loom body 7 4. A yarn bobbin holder 2, on which a yarn bobbin 3 is placed;

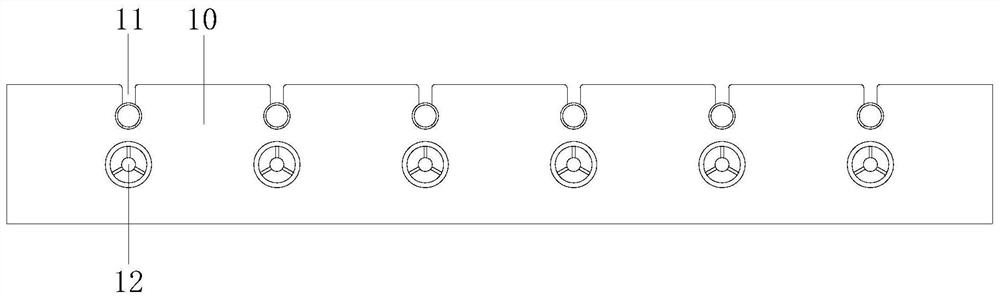

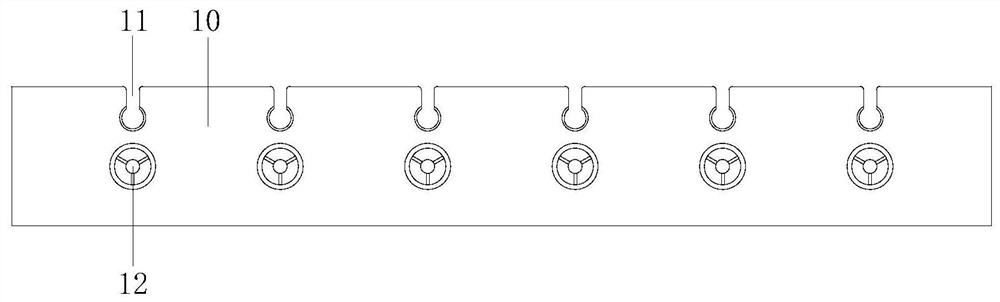

[0035] The wire passing device 1 includes a bracket 10, an opening 11, and a yarn porcelain hole closing mechanism 12. The br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com