Fabricated sloping roof construction method

A construction method and technology for sloping roofs, applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve problems such as poor installation and fixation stability, difficulty in lifting and lifting, and weak safety, and achieve assembly Simple, improve construction efficiency and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

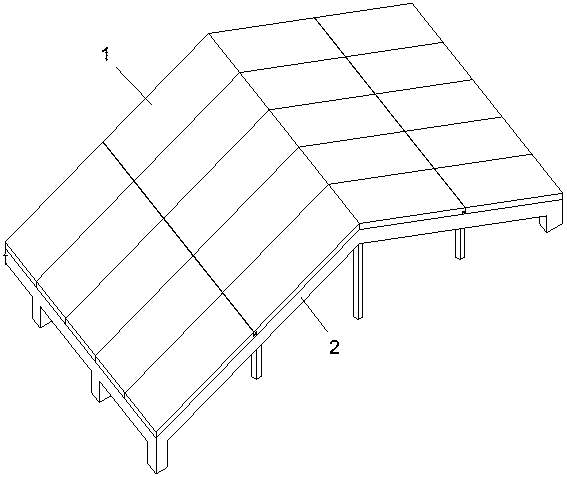

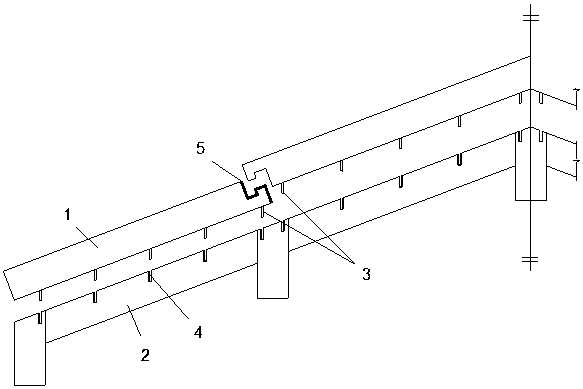

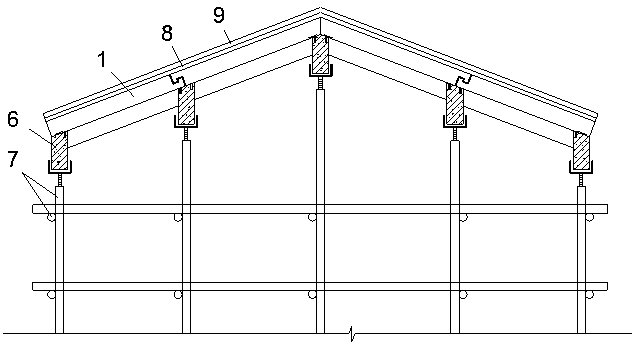

[0035] Such as figure 1 , 2 , Shown in 3, 4, a kind of prefabricated inclined roof construction method comprises the following steps:

[0036] S1. According to the requirements of the design drawings, check the overall size of the sloped roof, model through BIM software, visualize the building, and determine the size and position of the beam 2;

[0037] S2, such as figure 1 and 4 As shown, according to the center line of the longitudinal and transverse beams 2, the overall layout of the inclined roof is divided into several rectangular roof panels 1, and each roof panel 1 is numbered;

[0038] S3. Prefabricate the roof panel 1 in the prefabrication field. The prefabricated panel shown is a one-way prefabricated panel. A circle of socket anchor rods 3 is pre-buried ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com