Multistage yielding double-pipe restraint type self-resetting buckling-restrained support device

A technology of anti-buckling support and double tubes, which is applied in the direction of earthquake resistance, building type, building maintenance, etc., can solve the problems of energy dissipation capacity reduction, tension-compression hysteresis asymmetry, stiffness degradation, etc., to increase earthquake energy dissipation, Effect of dissipating seismic energy input and stabilizing self-resetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

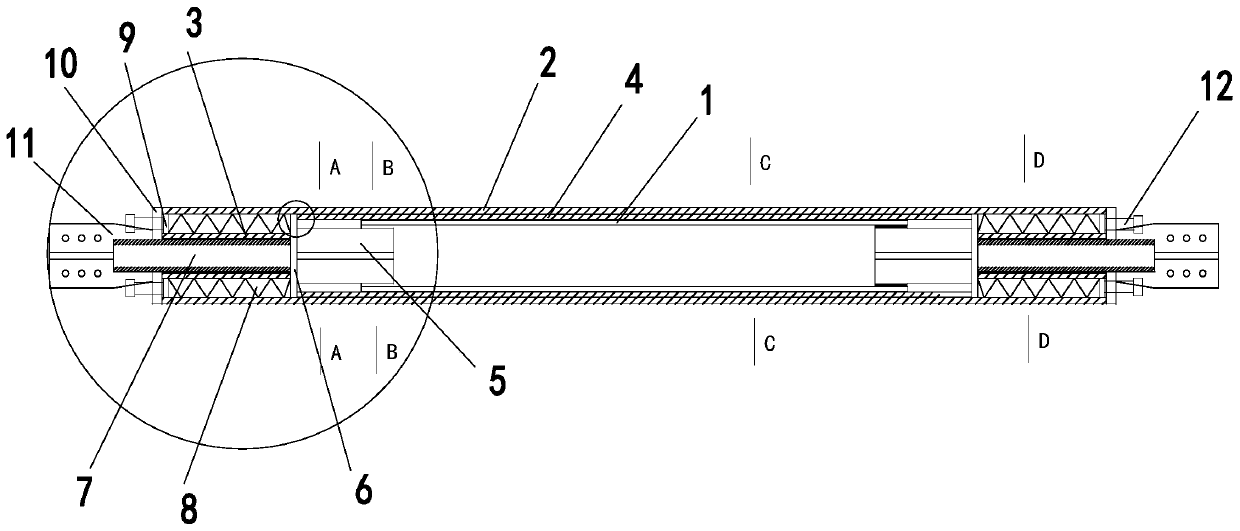

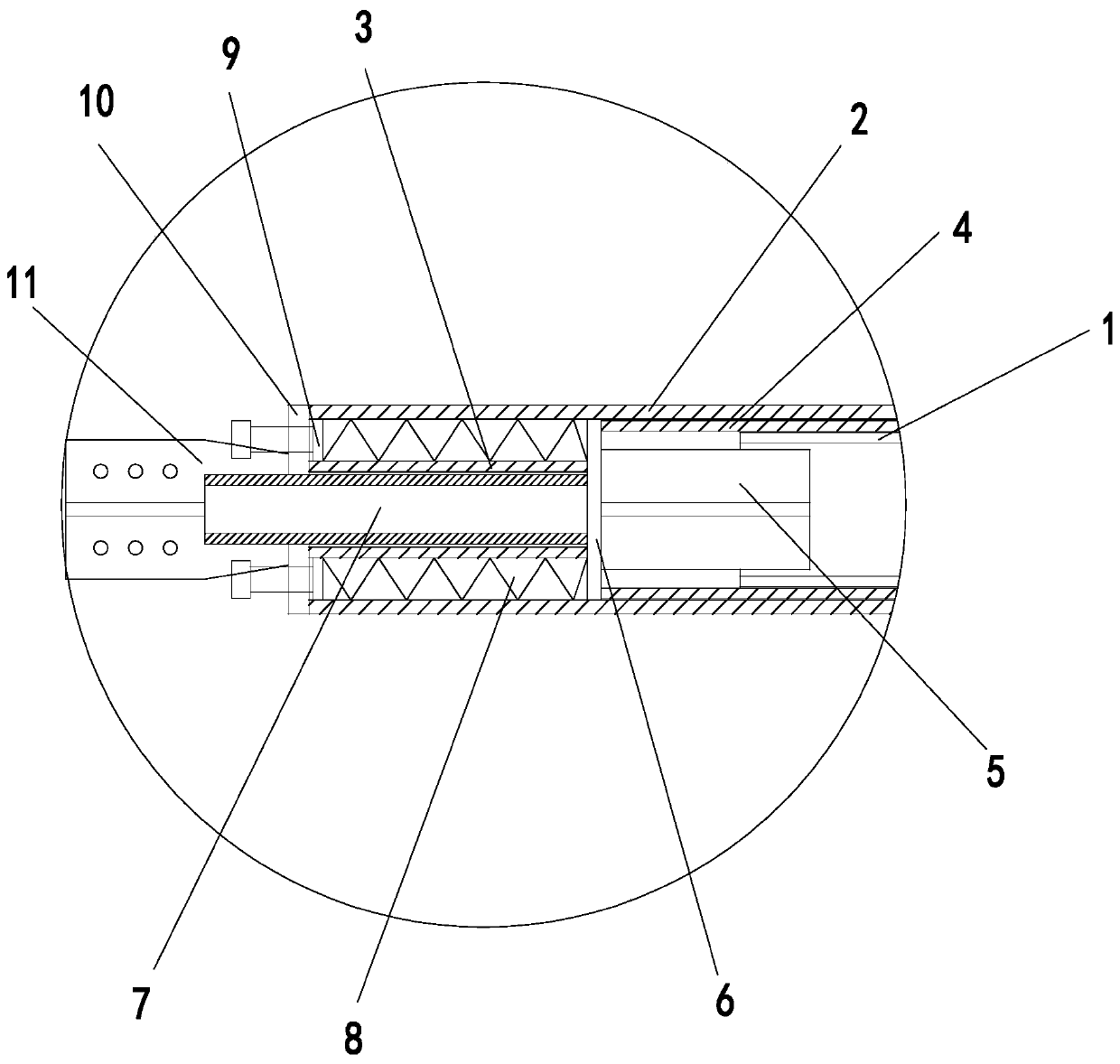

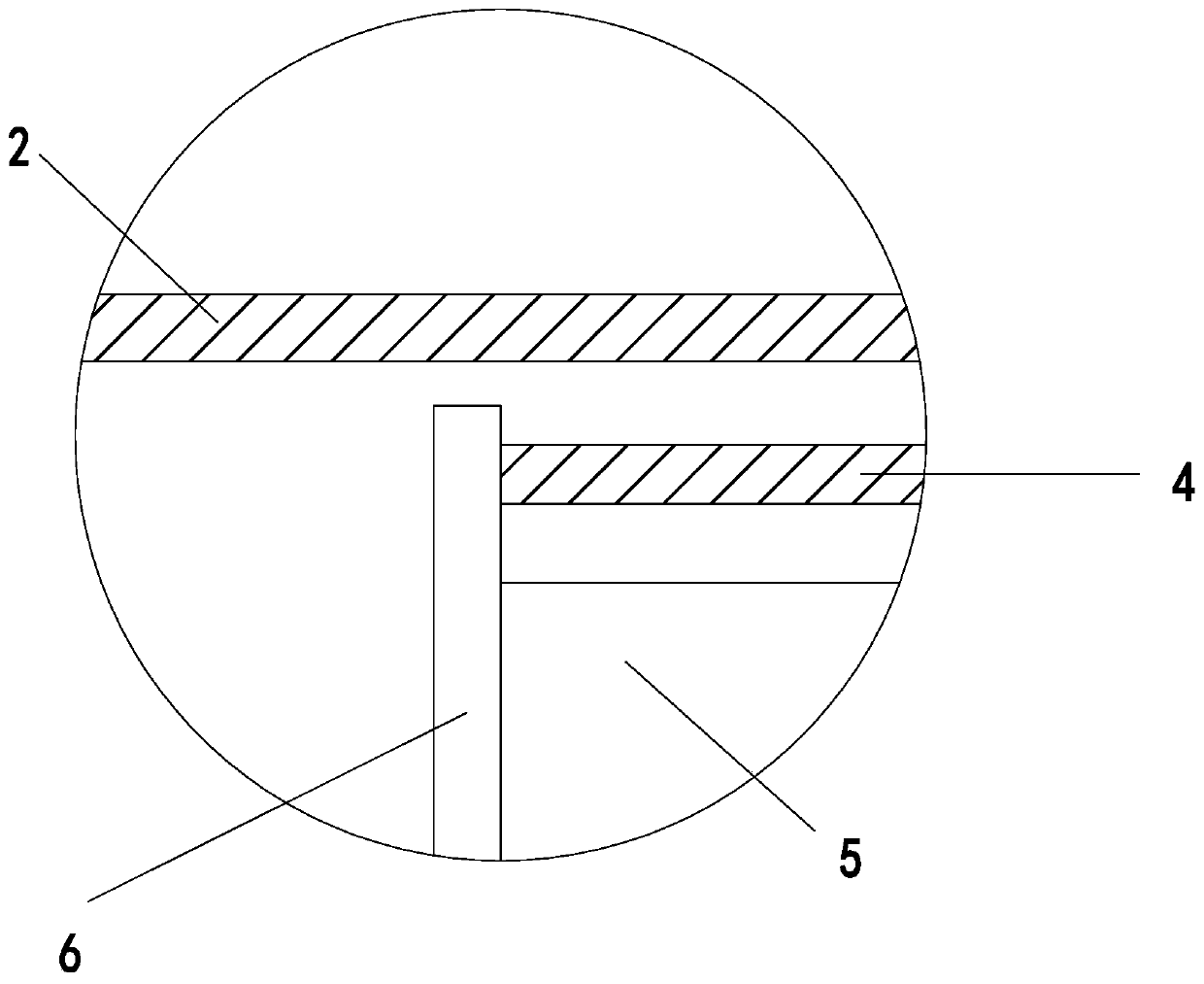

[0029] A self-resetting anti-buckling support device with multi-stage yielding dual-tube restraint, refer to Figures 1 to 6 , including inner restraint steel pipe 1, outer restraint steel pipe 2, first-level energy-dissipating steel pipe 3, second-level energy-dissipating steel pipe 4, two conduits 7, two positioning plates 5, two positioning end plates 6, and two outer end plates 10 , two connecting end plates 11, two groups of butterfly springs 8, two inner end plates 9; one end of the positioning plate 5 is inserted into the two ports of the internal constraint steel pipe 1 respectively, and the positioning plate 5 and the internal constraint steel tube 1 are all inserted into the interior of the secondary energy-dissipating steel pipe 4, and the two ends of the secondary energy-dissipating steel pipe 4 and the ports of the two positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com