Method for generating and distributing standard punch fixing seats

A distribution method and fixed seat technology, applied in the field of intelligent mold design and manufacturing, can solve the problems of environmental complexity and no mathematical model, achieve fast learning and knowledge accumulation, improve design efficiency and rationality, and eliminate repetitive labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, invention is described in further detail.

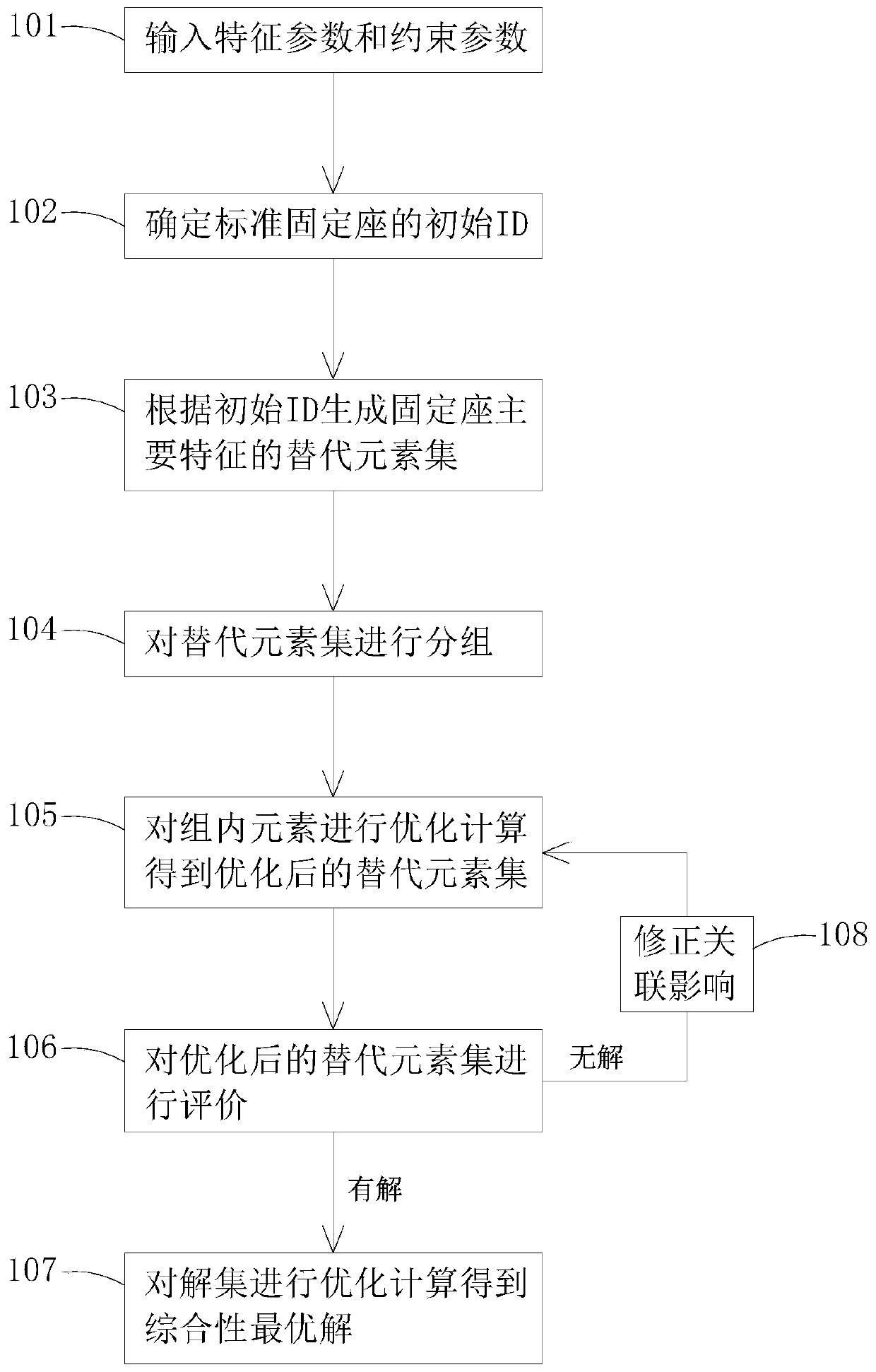

[0024] figure 1 It is a schematic flow chart of the design and implementation method of the working insert in the embodiment of the present invention.

[0025] Such as figure 1 As shown, the generation and distribution method of the standard punch holder mainly includes the following steps:

[0026] Step 101: Input feature parameters and constraint parameters.

[0027] The characteristic parameters include coordinate system and diameter, and the constraint parameters include: size, material thickness, cost and so on.

[0028] Step 102: Determine the initial ID of the standard holder.

[0029] Specifically, the matching calculation is performed based on constraint parameters such as the size, material thickness, and cost of the standard fixing seat, and the corresponding initial ID of the fixing seat is obtained from the database. A standard fixed seat has a series of charact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com