Puffed food processing device

A processing device and puffed food technology, applied in food forming, mixer with rotating stirring device, food science, etc., can solve problems such as easy drop of seasoning, waste of seasoning, insufficient puffing of raw materials, etc., to improve puffing time , Increase the degree of puffing, slow down the effect of the speed of decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Please refer to Figure 1 to Figure 8

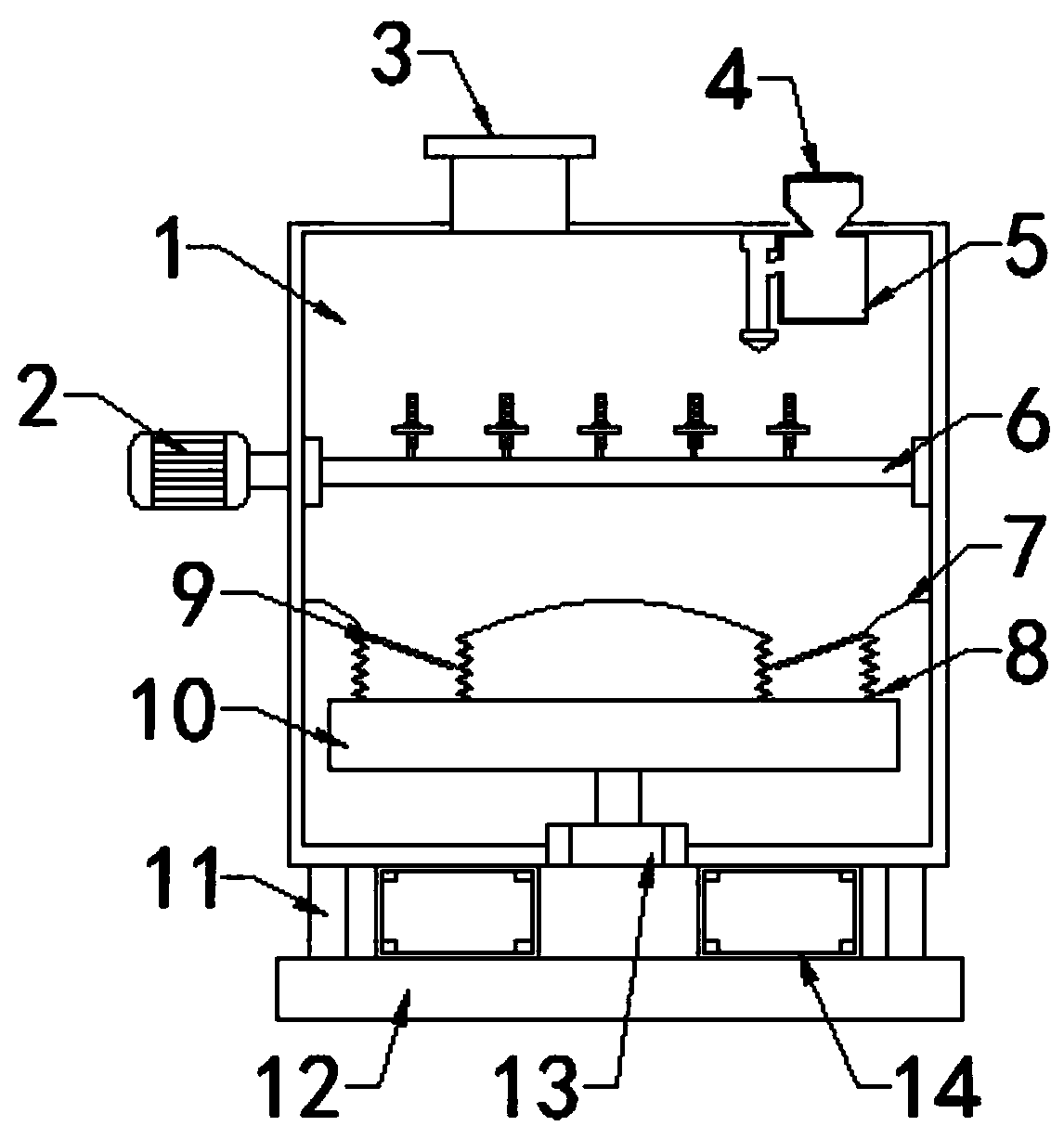

[0027] The present invention proposes a puffed food processing device, comprising: a processing device 1, a support plate 12 and a cavity 34; two pillars 11 are arranged at the lower end of the processing device 1, and the support plate 12 is fixedly connected to the bottom of the pillars 11.

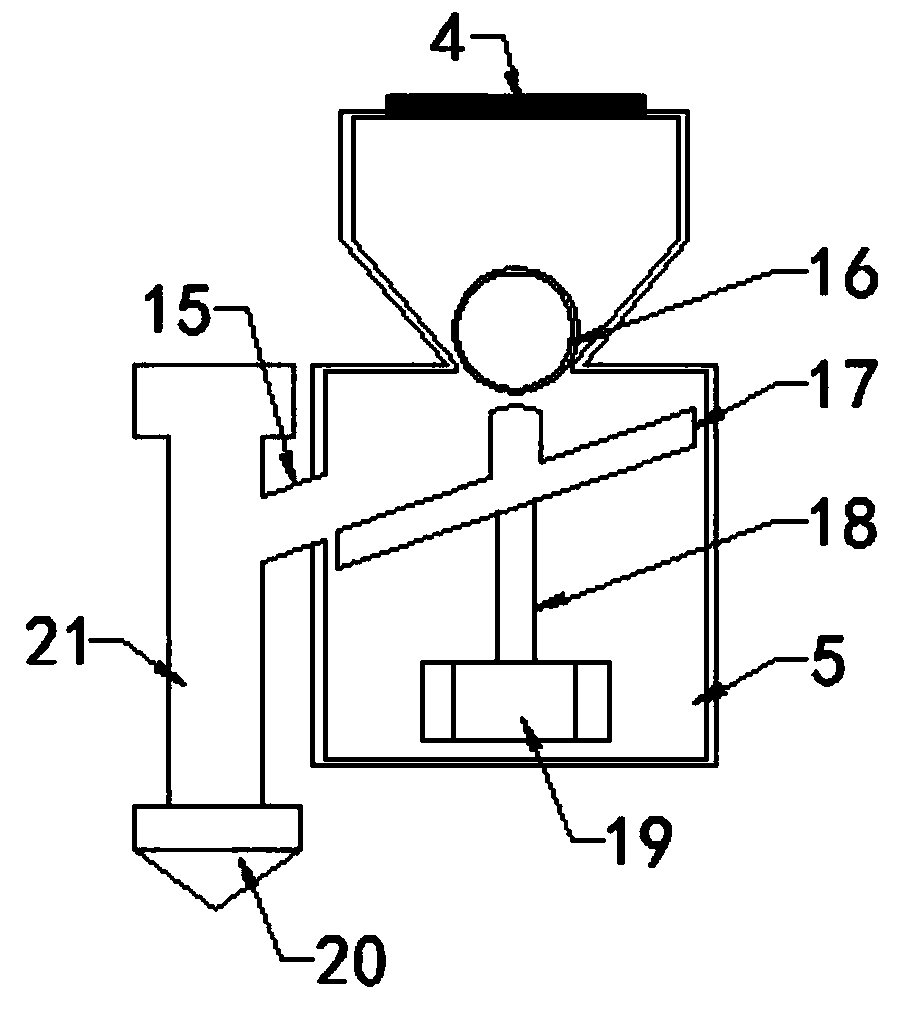

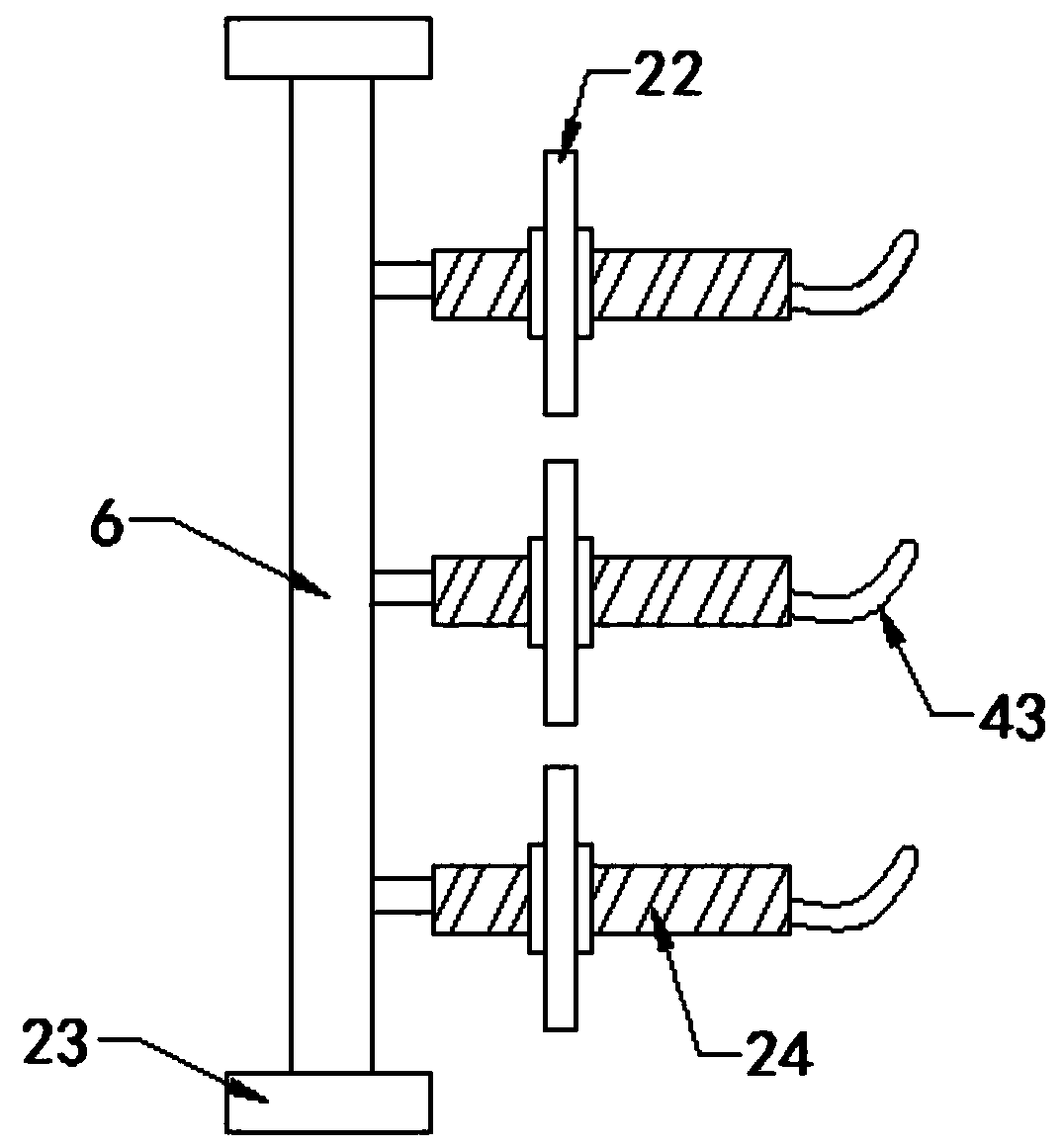

[0028] At the same time, the inside of the processing device 1 includes a feed box 5, a horizontal plate 6 and a connecting cavity 26. The top of the processing device 1 is provided with a feed port 3, and the left end of the processing device 1 is fixedly connected with a motor 2. The inside of the processing device 1 The bottom is provided with a hydraulic cylinder 13, and the upper end of the hydraulic cylinder 13 is provided with a connecting plate 10, and the upper end of the connecting plate 10 is clamped with four folded plates 8, and the inner side of the two folded plates 8 is movably connected with a movable plate 9, and the folde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com