Hot melting type 3D printing consumable connector

A 3D printing and connector technology, applied in the field of 3D printing, can solve the problems of huge wire and 3D printer consumables used, waste, etc., to achieve high connection success rate, high connection efficiency, and reduce burrs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

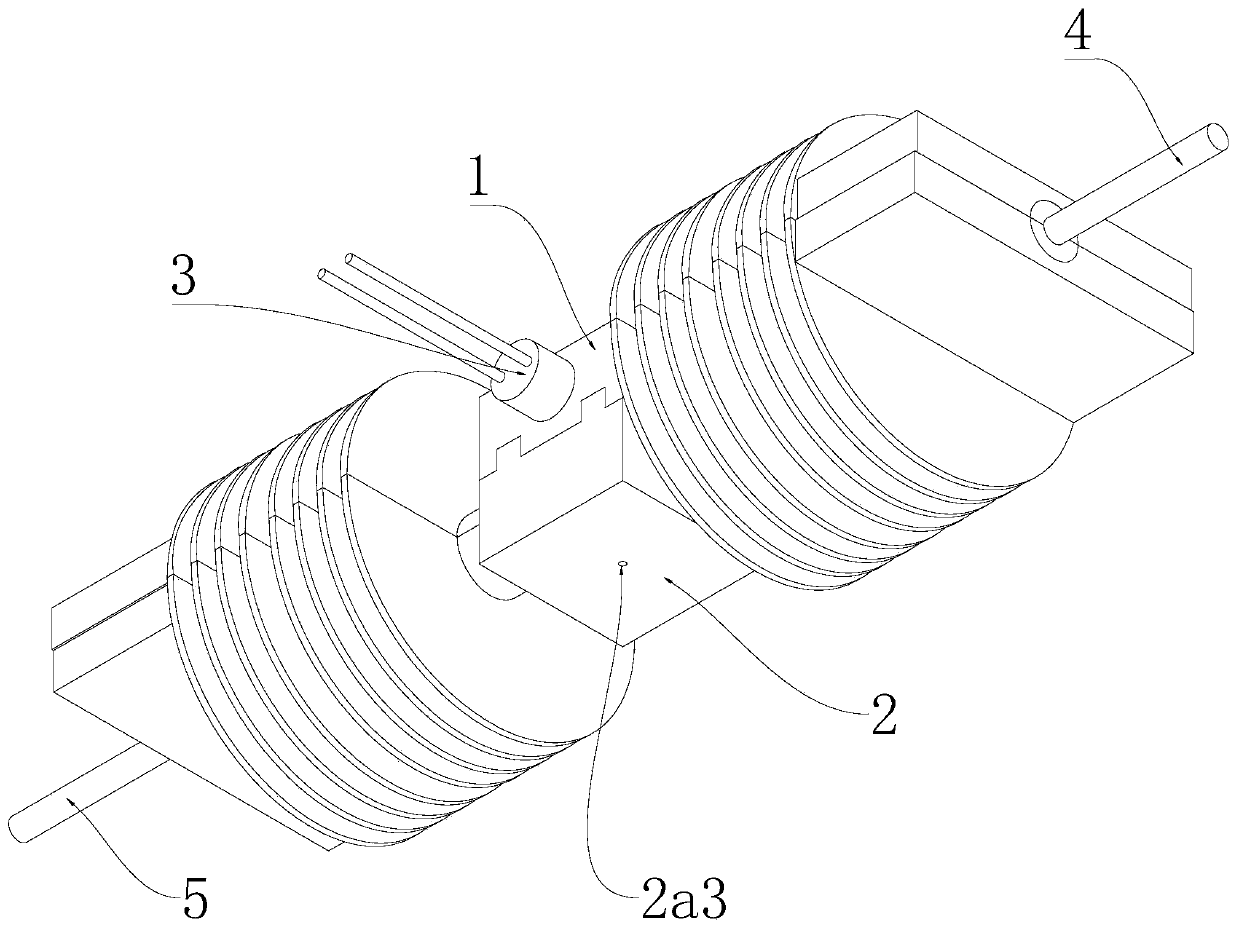

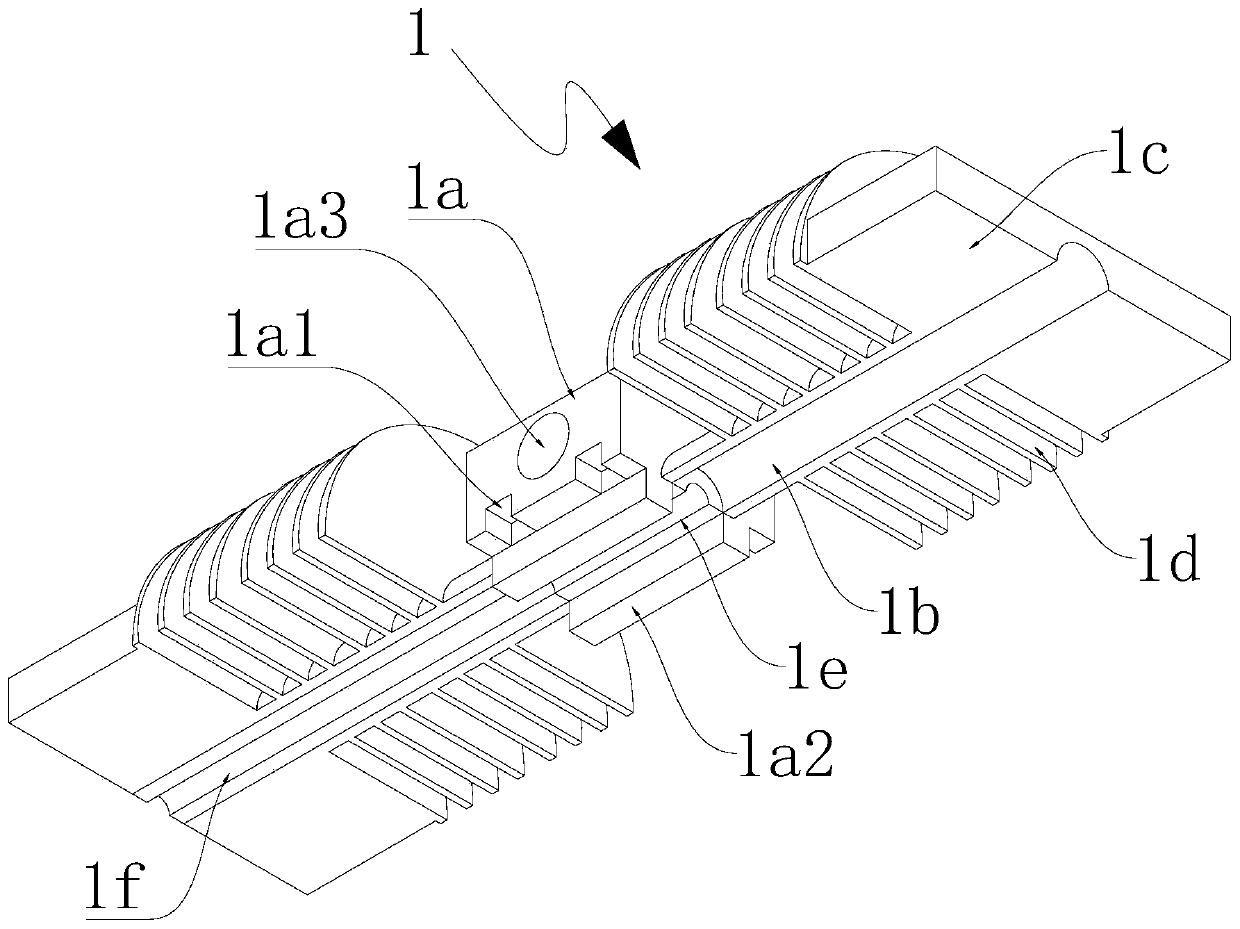

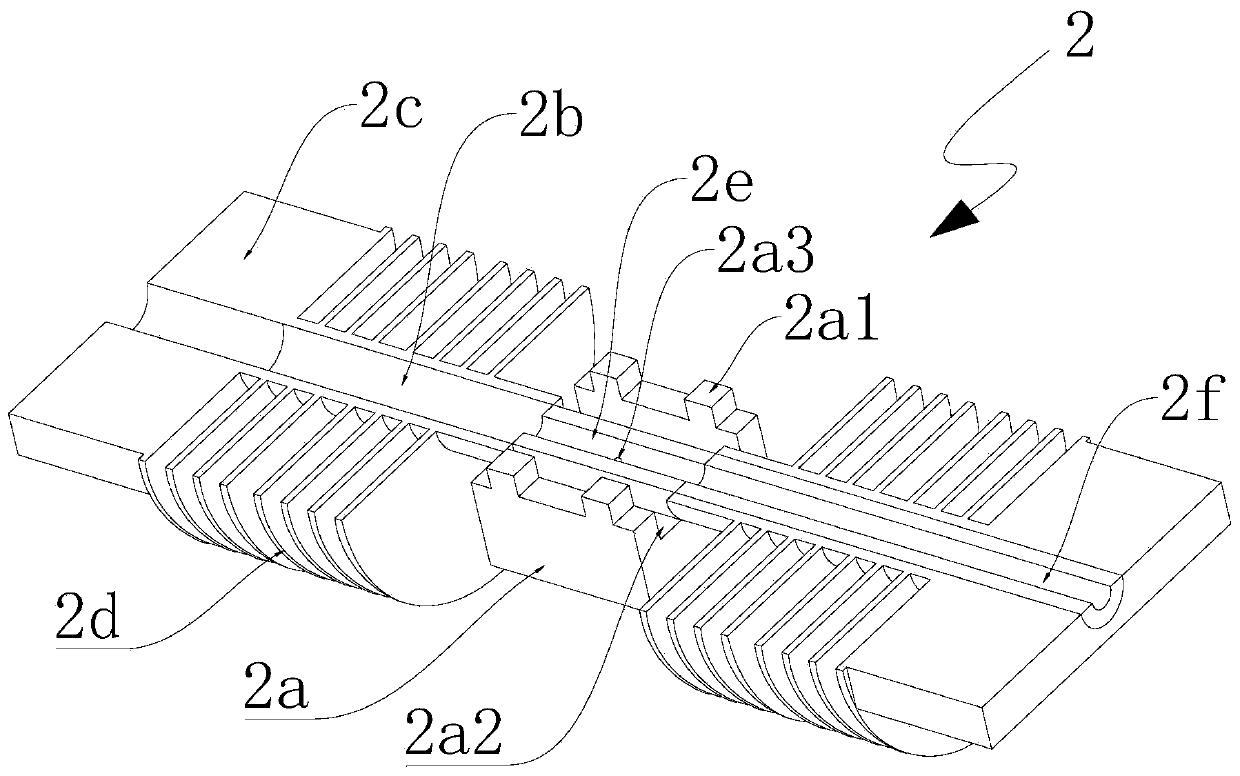

[0028] Such as figure 1 As shown, a hot-melt 3D printing consumable connector includes an upper connecting part 1, a lower connecting part 2 and a heating part 3, such as figure 2 As shown, the upper connection part 1 includes an upper heating chamber 1a and upper cooling fixtures symmetrically arranged on both sides of the upper heating chamber 1a. The upper cooling fixture includes an upper cooling channel 1b and an upper fixing splint 1c. One end of the cooling channel 1b is connected to the upper heating chamber 1a, and the other end is connected to the upper fixing splint 1c. The center position of the lower surface of the upper heating chamber 1a is embedded with an upper consumable slot 1e along the axial direction of the upper cooling channel 1b. Upper positioning p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com