Z-PIN enhanced honeycomb sandwich plate and moulding process thereof

A Z-PIN, 1.Z-PIN technology, applied to other household appliances, household appliances, flat products, etc., to achieve uniform mechanical properties, ensure implant depth, and reduce implant resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

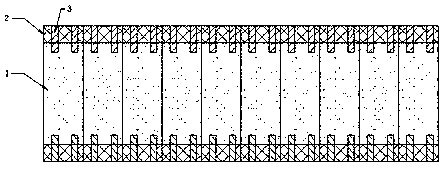

[0033] Combine below figure 1 Embodiments of the present invention are described in detail.

[0034] Z-PIN reinforced honeycomb sandwich panel, including a honeycomb core 1 filled with foam and a skin 2 cured and bonded to the upper and lower surfaces of the honeycomb core 1, characterized in that Z-PIN is implanted in the skin 2 The needle 3, the Z-PIN needle 3 penetrates the skin 2 and is inserted into the foam of the honeycomb core 1 .

[0035] In the Z-PIN reinforced honeycomb sandwich panel shown in the figure, the Z-PIN needle 3 is implanted into the foam of the skin 2 and the honeycomb core 1, which not only increases the reinforcement of the skin 2, but also strengthens the foam surface of the honeycomb core. Reinforcement is carried out to improve the compressive performance of the foam sandwich. When the skin is cured, the foam core can withstand greater curing pressure, improve the curing effect of the skin, and make the mechanical properties of the skin more unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com