Abutted seam aligning device and control method thereof

A technology for supporting devices and mounting plates, used in decorative arts, manufacturing tools, manipulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

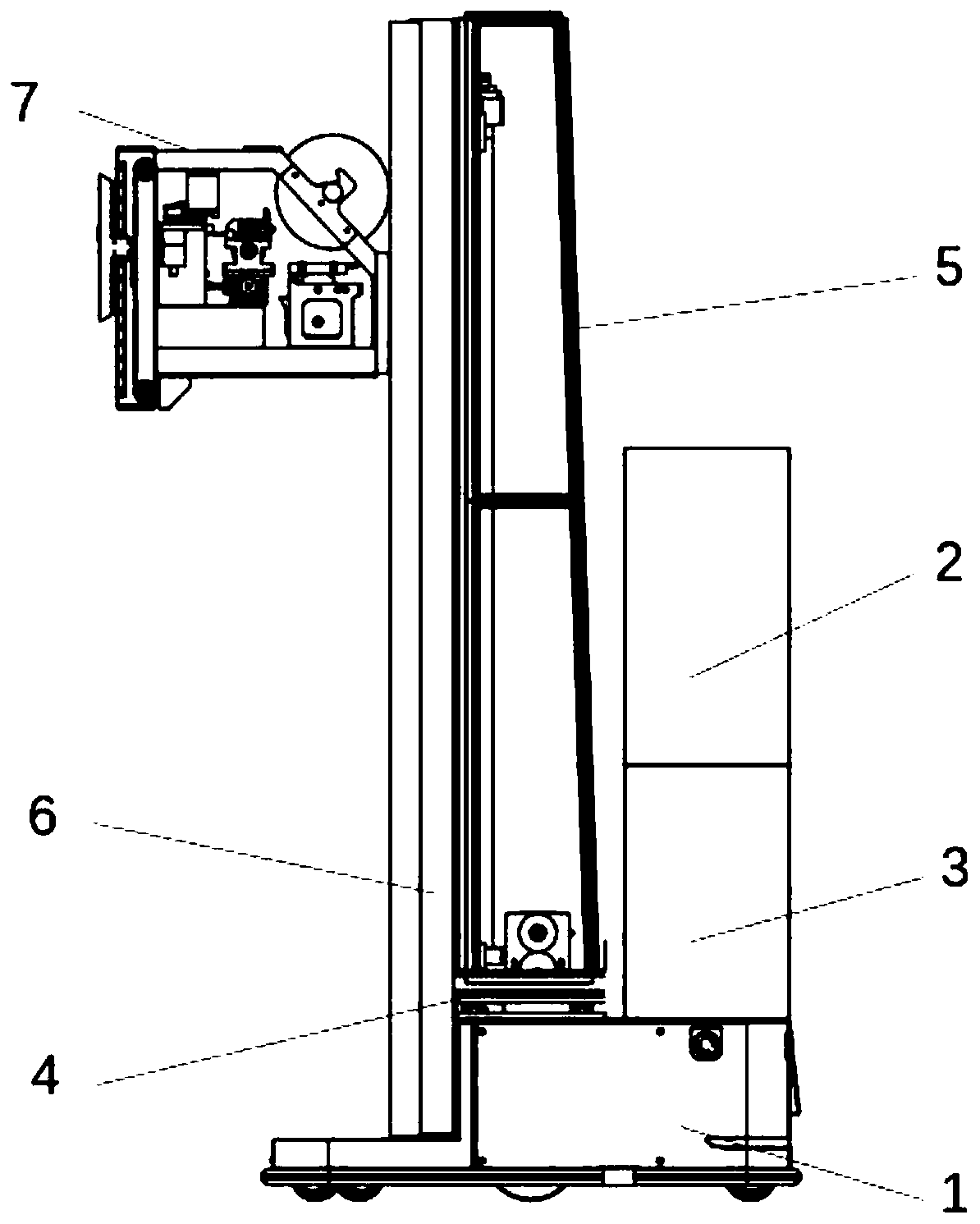

[0031] Such as Figure 1-3 As shown, this embodiment provides a seam alignment device, the seam alignment device includes a main frame 5 and a guide car 1, and the seam alignment device is arranged between the main frame 5 and the guide car 1, so that the main frame 5 is positioned between the guide car 1 1. When moving up, the horizontal position adjustment is realized, and then the seam alignment adjustment is realized.

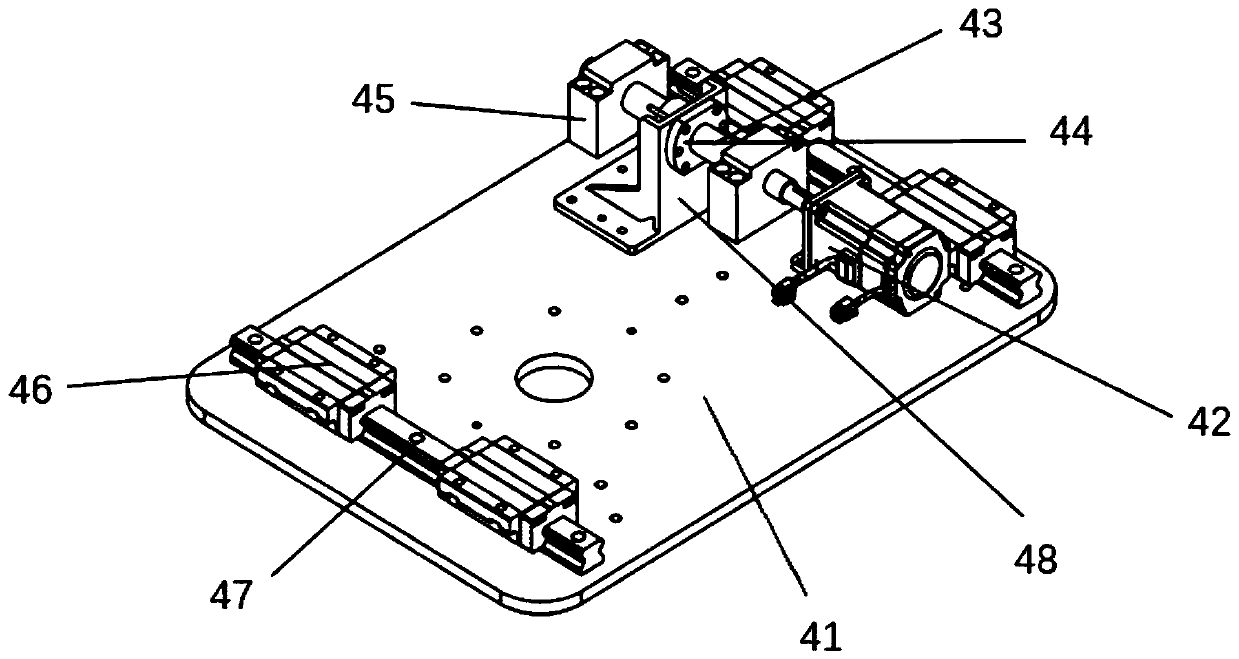

[0032] Further, such as Figure 1-3 As shown, the seam alignment device is fixed on the guide car 1, the main frame 5 is movably arranged on the seam alignment device, and the seam alignment device 4 includes a drive assembly and a mounting plate 41; the mounting plate 41 is fixedly arranged on the guide car 1 , the driving assembly is arranged on the mounting plate 41, and it includes an active assembly and a driven assembly. The active assembly drives the main body frame 5 to perform an alignment movement along the horizontal direction. 41 to move back ...

Embodiment 2

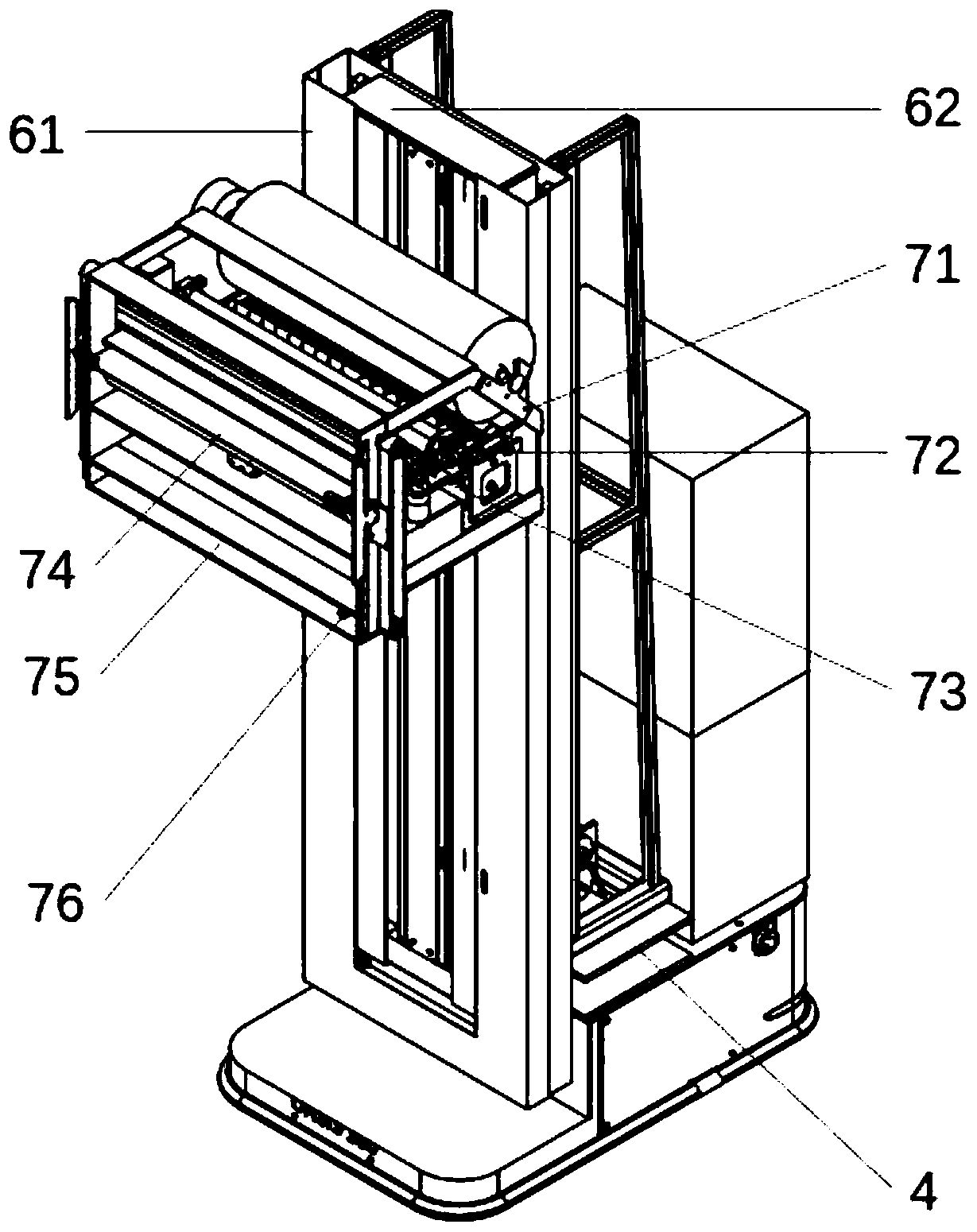

[0040] The above embodiments provide a seam alignment device. This embodiment aims to provide a wallpaper laying robot with the seam alignment device described in Embodiment 1, such as Figure 1 to Figure 3 As shown, it includes a guide car 1, a main frame 5, a rising module 6, a paving mechanism 7, and a seam alignment device 4; wherein, the guide car 1 is an AGV trolley, which is mainly used to pull the main frame 5 to realize wallpaper paving The seam alignment device 4 is arranged between the main frame 5 and the guide vehicle 1, so that the main frame 5 can move in the horizontal direction relative to the guide vehicle 1, thereby adjusting the horizontal position between the main frame 5 and the guide vehicle 1, and then adjusting The distance between the main frame 5 and the body of wall; since the paving mechanism 7 is arranged on the main frame 5, the distance between the main frame 5 and the body of wall can be adjusted by adjusting the distance between the paving mech...

Embodiment 3

[0049] Correspondingly, combining the above schemes, such as Figure 1 to Figure 3 As shown, the present embodiment provides a method for adjusting a wallpaper laying robot, including the following process:

[0050] The distance detection device on the wallpaper laying robot collects the distance between the last piece of wallpaper and the wallpaper roller;

[0051] When the distance is greater than the preset value; the wallpaper paving robot adjusts the horizontal position between the main body frame 5 and the guide vehicle 1 through the seam alignment device 4, until the wallpaper on the wallpaper roller 74 is close to the wall, and is pasted with the previous one. The wallpaper is closely connected, and the wallpaper laying robot is controlled to start wallpaper laying.

[0052] Preferably, in combination with the above schemes, such as Figure 1 to Figure 3 As shown, the distance detection device provided by the present invention is a laser vision sensor 76. The laser v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com