Mechanism for improving module brightness performance consistency after assembly of liquid crystal screen and backlight module

A technology of backlight module and LCD screen, applied in optics, nonlinear optics, instruments, etc., can solve problems such as unfavorable product stability and consistency principle, uneven product brightness, etc., to improve the one-time pass rate and ensure brightness The effect of improving consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, the concrete structure of the present invention is as follows:

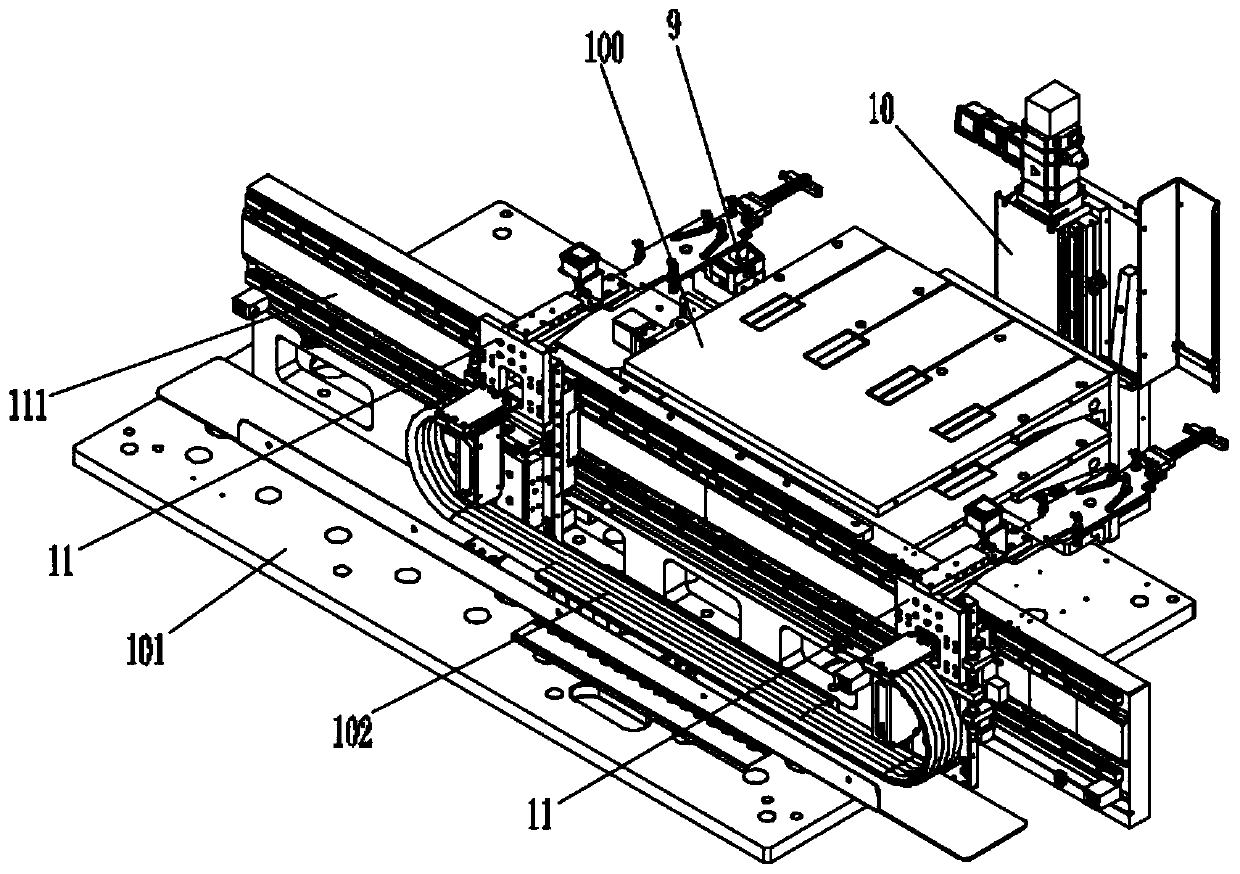

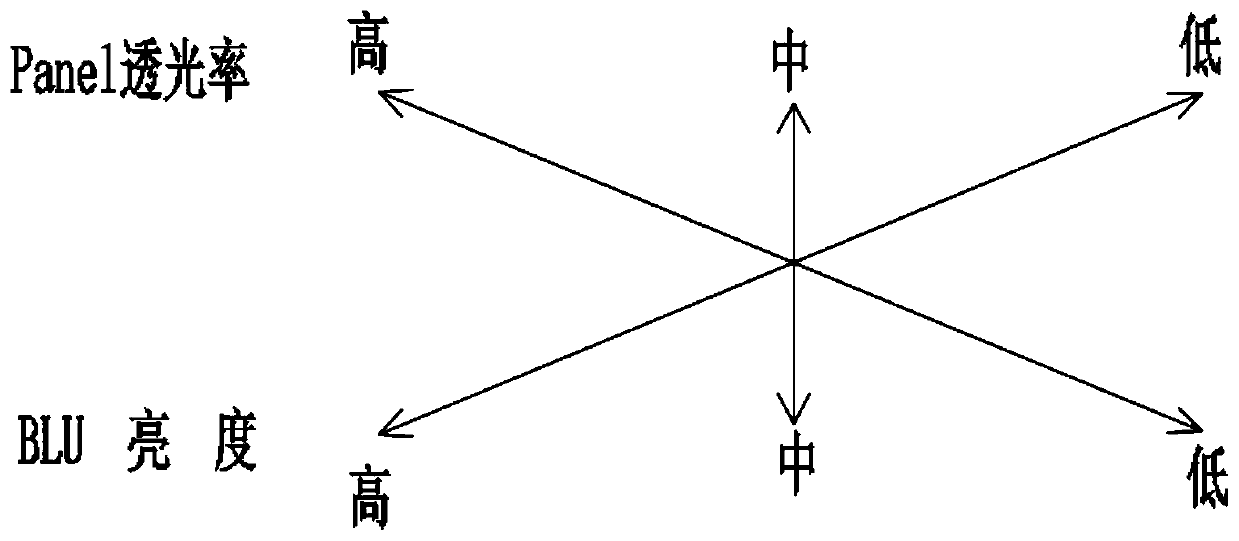

[0031] Please refer to the attached Figure 1-2 According to the present invention, the mechanism for improving the brightness performance consistency of the liquid crystal screen and the backlight module after assembly includes an assembly device for matching and assembling the liquid crystal screen and the backlight module, and also includes:

[0032] The liquid crystal screen conveying mechanism that is located on a first platform 101, this liquid crystal screen conveying mechanism includes an incoming material scanning code device 9 for identifying the penetration rate of the liquid crystal screen, a linear stroke 111 with side rails, a A sorting manipulator mechanism 11 arranged on the side rail and capable of moving in the X-axis along the side rail, and a sorting manipulator mechanism 11 set on the opposite side of the sorting manipulator mechanism 11 and storing the penetration rate o...

Embodiment 2

[0043] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the liquid crystal screen conveying mechanism of the present invention.

[0044] First of all, the liquid crystal screen in the present invention is provided with a two-dimensional code, and the two-dimensional code stores three types of transmittance information: high, medium and low. In the present invention, the multi-layer liquid crystal screen storage board 100 is arranged in three layers, from top to bottom:

[0045] The first layer of liquid crystal screen storage board is a high-transmittance liquid crystal screen storage board, which is used to store high-transmission liquid crystal screens;

[0046] The second layer of liquid crystal screen storage board is a liquid crystal screen storage board with medium transmittance, which is used to store liquid crystal screens with medium transmittance;

[0047] The third layer of liquid crystal screen storage board is a low-transmittance liqui...

Embodiment 3

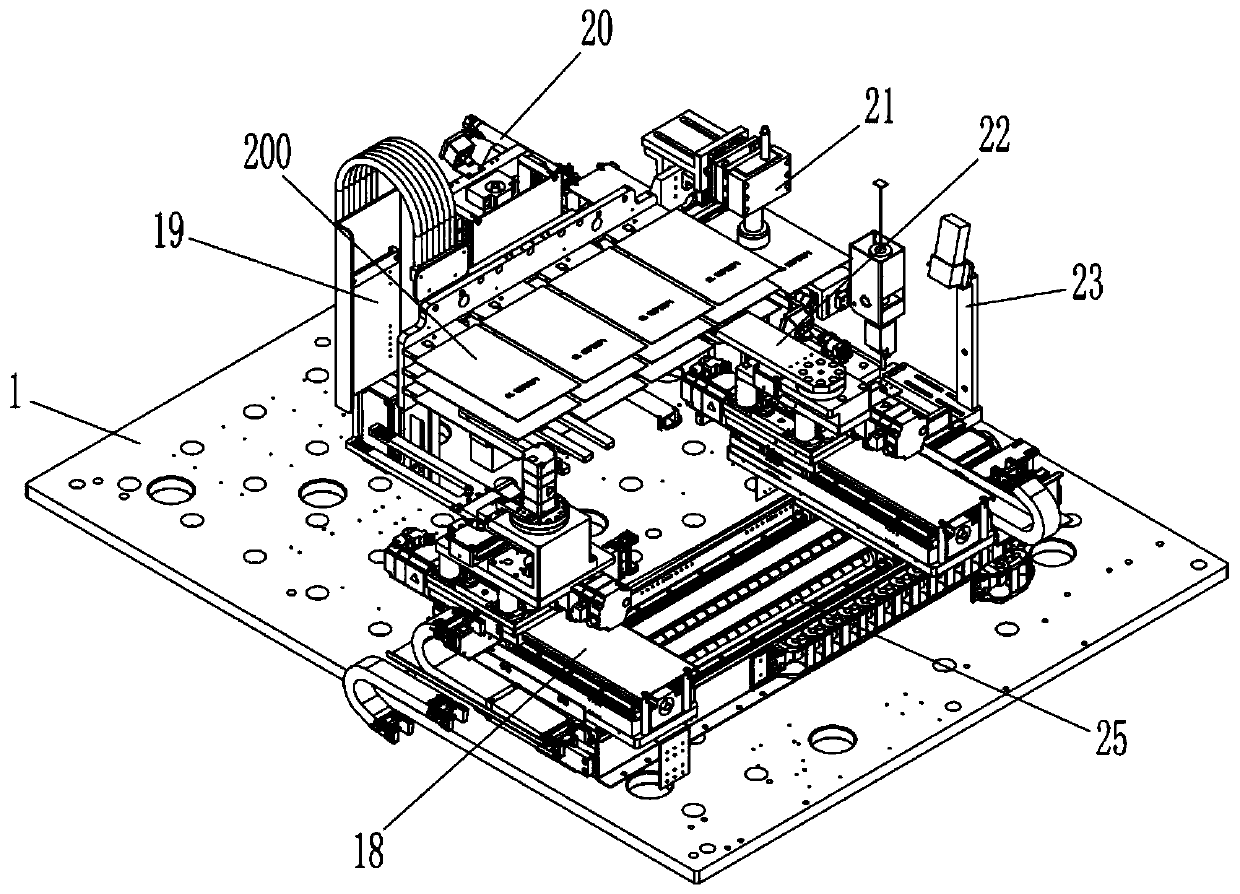

[0050] Such as figure 2 as shown, figure 2 It is a structural schematic diagram of the conveying mechanism of the backlight module of the present invention.

[0051] The backlight module loading manipulator transports the backlight module to the backlight module scanning position, provides position marks for the classification and storage of backlight modules by scanning the QR code on the backlight module, and then transports the backlight module through visual positioning and conveyance To the lighting station capable of lighting the backlight module, this station is also a brightness detection station. Through the detection of the brightness detector 21, it is distinguished whether the brightness of the backlight module is one of high, medium and low brightness. Brightness classification storage mechanism 19. The backlight module grabbing mechanism 22 transports the backlight module according to the specific matching relationship to the assembly position and assembles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com