STM32 based intelligent valve controller and control method

A technology of intelligent controller and flow controller, which is applied in the direction of flow control, control/regulation system, non-electric variable control, etc. It can solve the problem that the influence of temperature change on density is not considered, the control method is not closed loop, and the closed loop cannot be realized. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

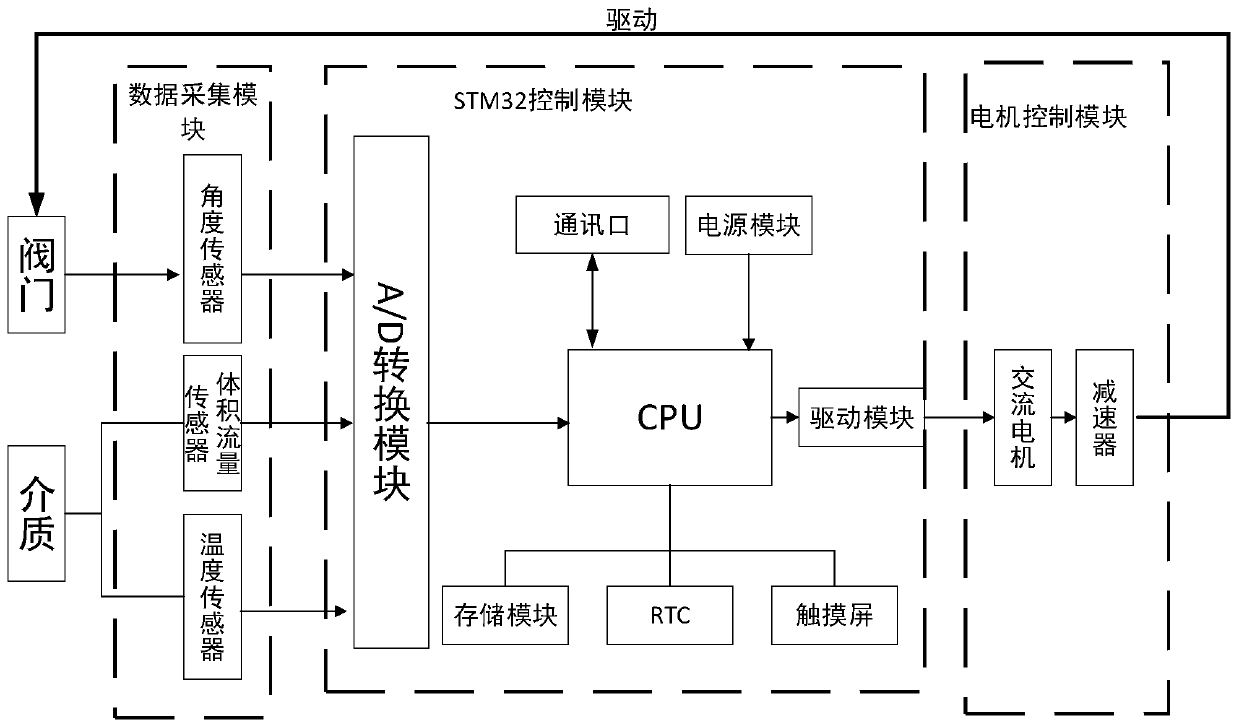

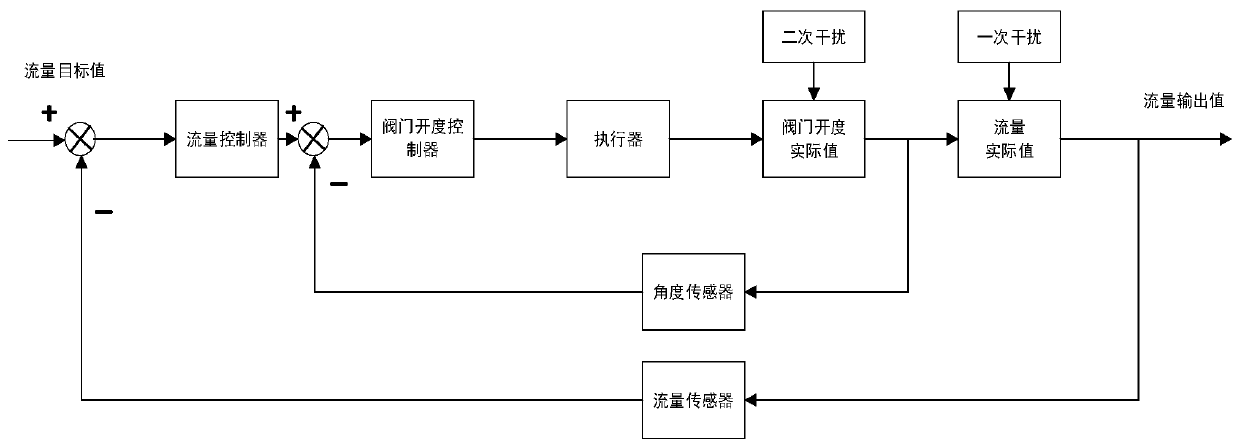

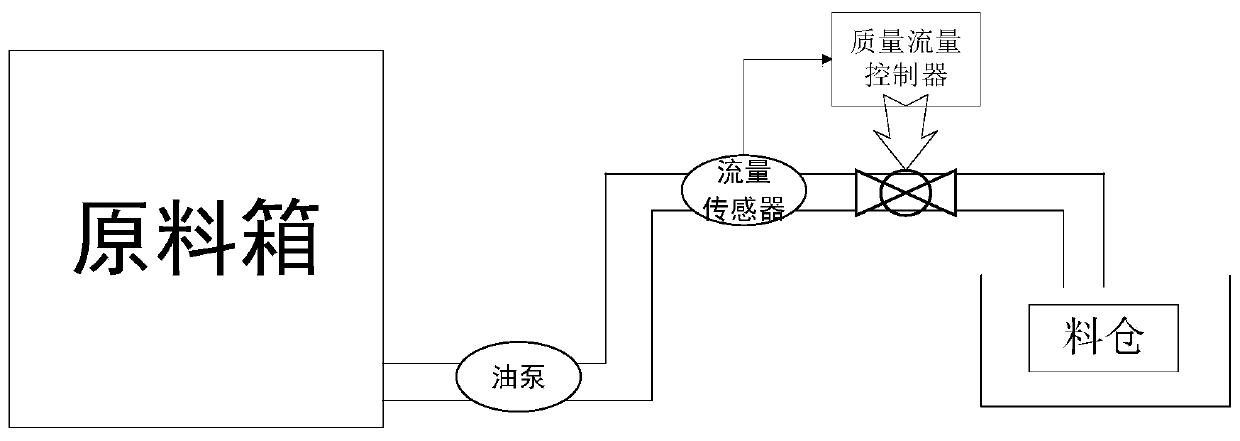

[0091] Such as figure 1 with figure 2 As shown, a valve intelligent controller based on STM32 of the present invention includes a data acquisition module, an STM32 control module and a motor control module, wherein,

[0092] The data acquisition module includes the temperature sensor and flow sensor placed in the controlled medium and the angle sensor built into the valve; the STM32 control module includes the main control CPU, storage module, A / D conversion module, clock module, touch screen, power supply module and drive module ; The motor control module includes an AC motor and a reducer;

[0093] Preferably in this embodiment, the main control CPU adopts the STM32F103RCT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com