Heat transfer limit modeling method for composite capillary core thermal column

A modeling method and capillary core technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems affecting real-time performance of simulation, and achieve good robustness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

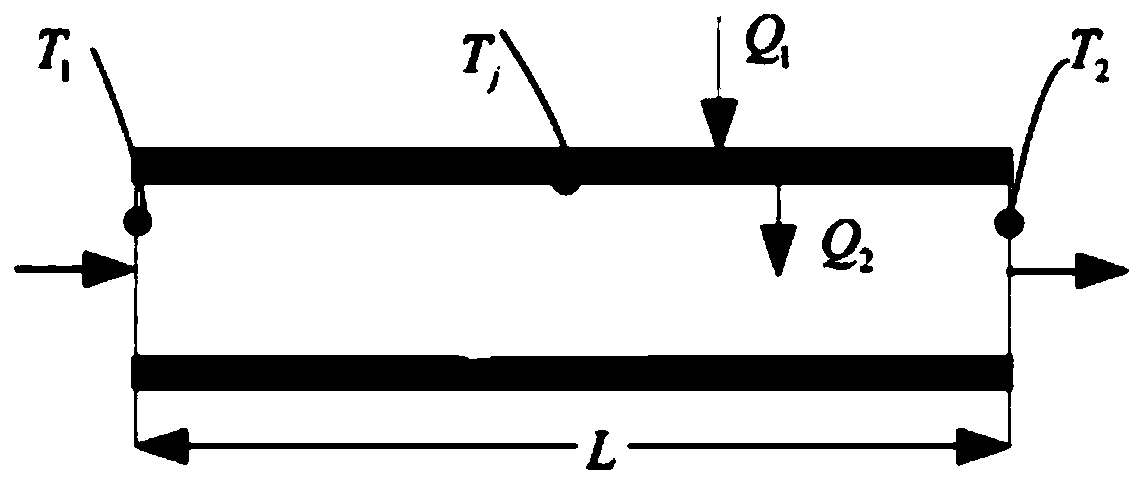

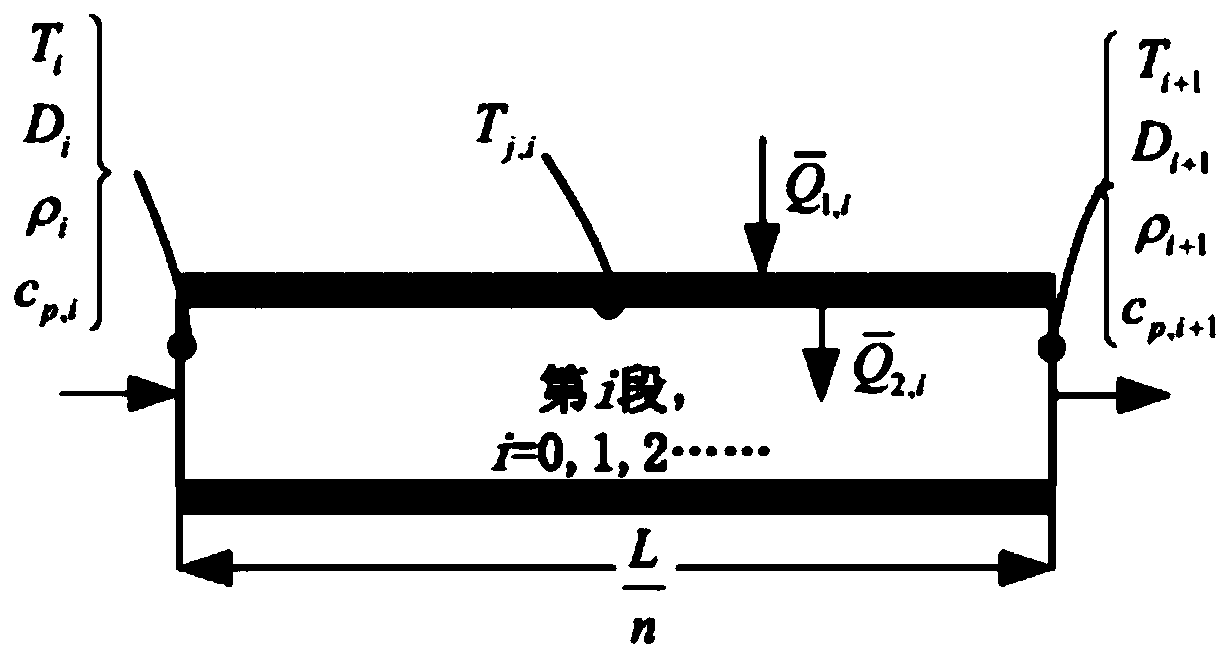

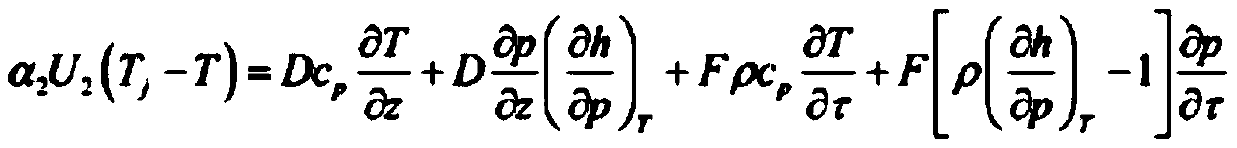

[0020] A heat transfer limit modeling method of a composite capillary core heat column is characterized in that it includes the following steps: Step 1, according to the thermodynamic state equation of the working fluid in the tube, respectively derive the partial differential equation of the enthalpy of the working fluid in the tube with the tube length and time Step 2, bringing the partial differential equation gained in step 1 into the energy conservation equation of working medium in the tube; Step 3, utilizing the dynamic process characteristics of the enthalpy-temperature channel of the single-phase heating tube, simultaneously separating the space-time two-dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com