Ultrasonic in-plane puncture positioning device

A positioning device and plane technology, applied in the direction of puncture needles, trocars, etc., can solve problems such as damage, inaccurate puncture, lack of precise puncture angle, puncture length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

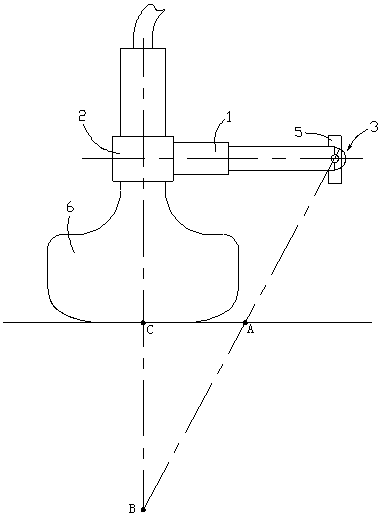

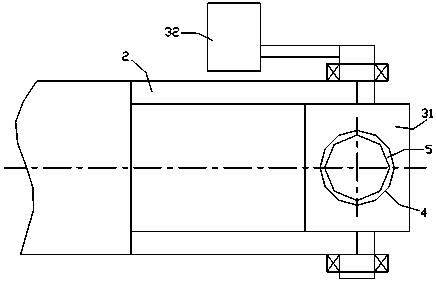

[0014] Combine below figure 1 and figure 2 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

[0015] The present invention provides a puncture positioning device in an ultrasonic plane, comprising a telescopic arm 1 that can be stretched laterally, and a clamp 2 for clamping an ultrasonic probe 6 of an ultrasonic machine is provided at the fixed end of the telescopic arm, so that the ultrasonic probe and the clamp are not separated. Relative movement occurs, and the use of clamps is also convenient for disassembly, which is beneficial to ordinary ultrasonic puncture. The axial centerline of the hoop coincides with the central axis of the ultrasonic probe, the transverse axis of the telescopic arm is perpendicular to the central axis, so that the telescopic arm is perpendicular to the ultrasonic probe; the telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com