A punch for hot air forming of metal pipe fittings

A technology for metal pipe fittings and metal pipes is applied in the field of punches for hot air pressure forming of metal pipe fittings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

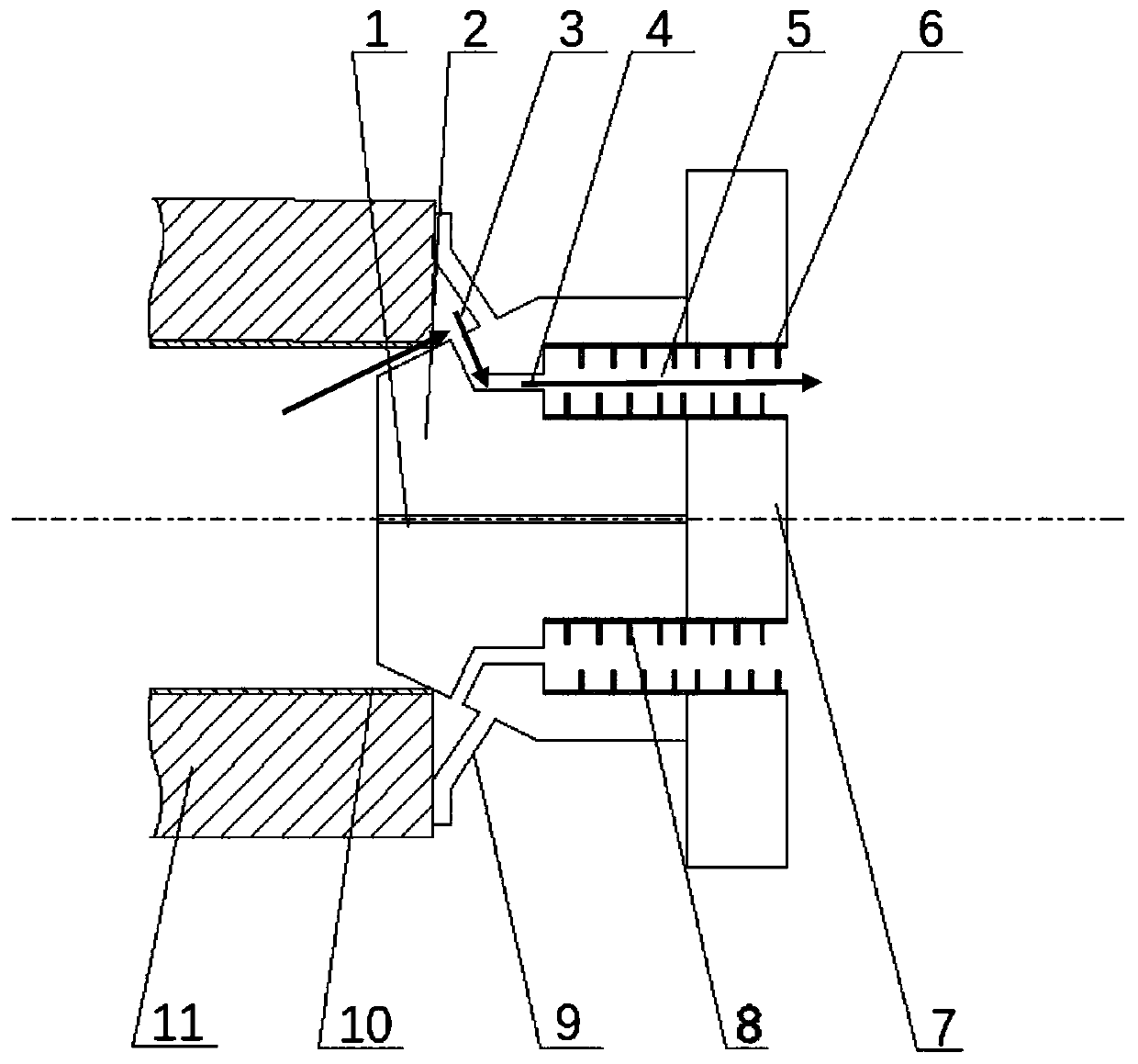

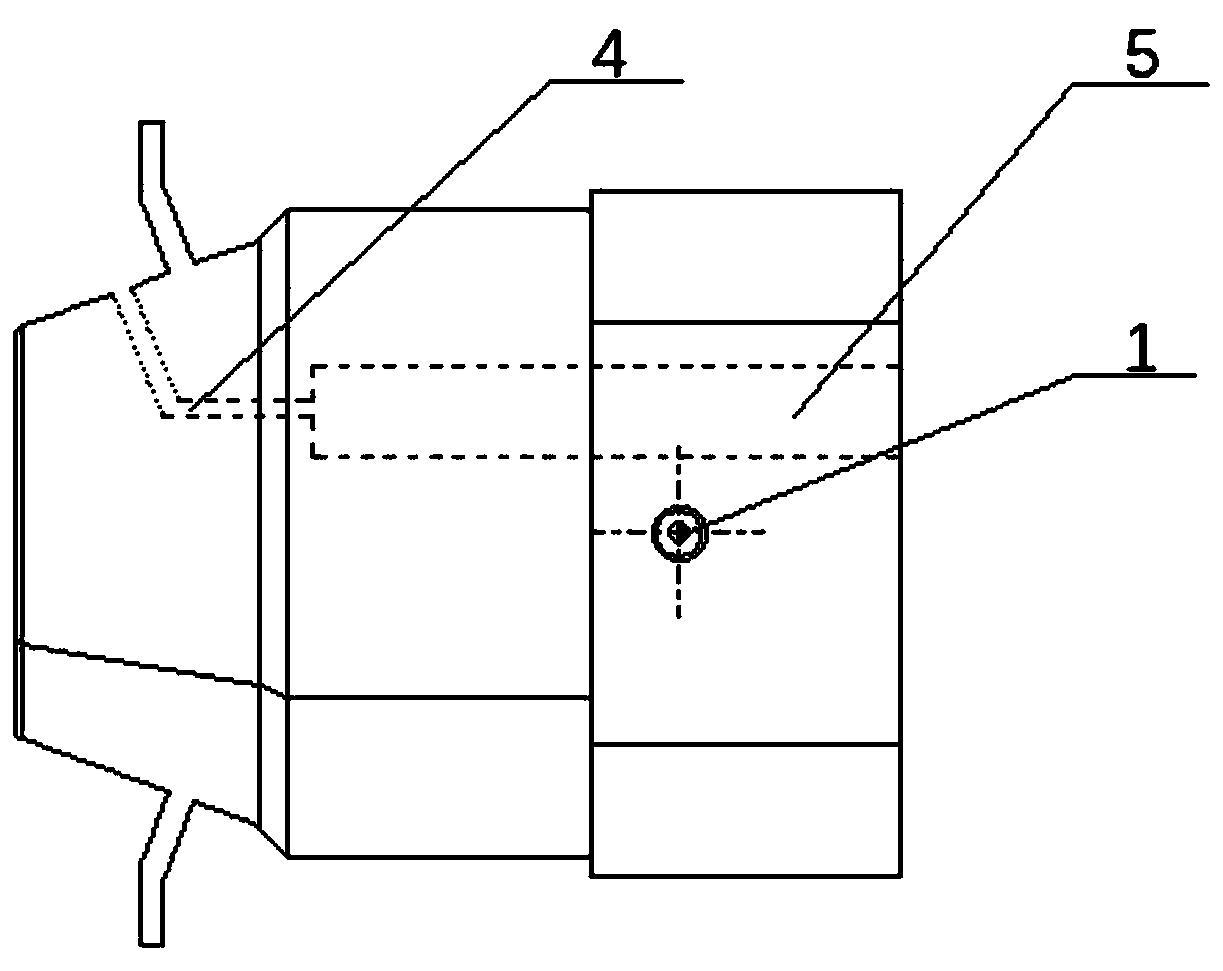

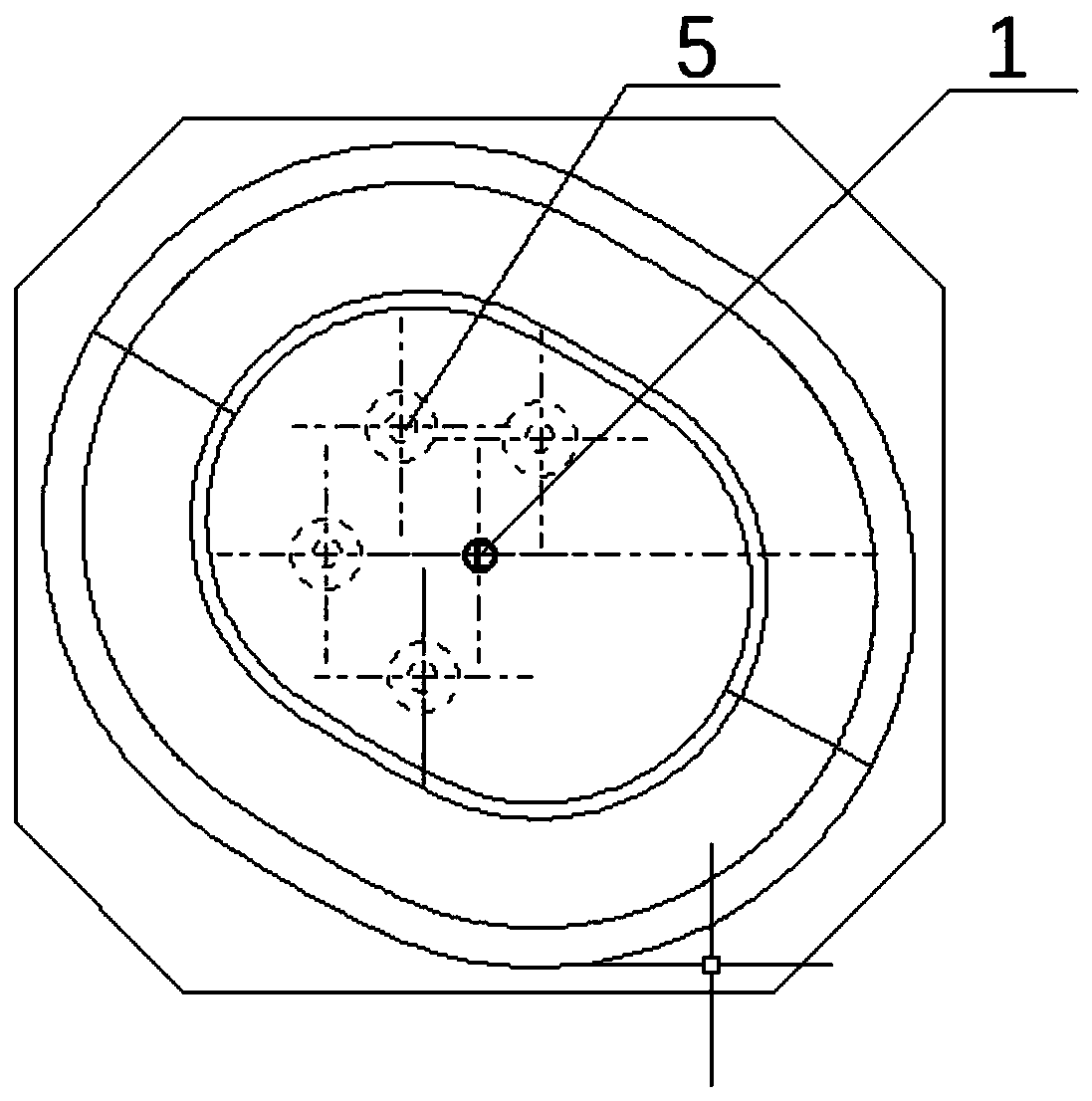

[0027] Example 1: Combining figure 1 , figure 2 and image 3 Description, a punch for hot air pressure forming of metal pipe fittings, including air inlet 1, punch cone 2, air chamber 3, exhaust pipe 4, anechoic chamber 5, two-component silencing cotton 6, flange 7. Silencer disc 8 and baffle plate 9.

[0028] The taper of the punch cone surface 2 is determined according to the diameter of the metal pipe 10. The length of the punch entering the metal pipe is 1 / 3 of the cone surface, and there is a baffle 9 perpendicular to the cone surface at 2 / 3 of the cone surface. In order to strengthen the air chamber To ensure the best sealing effect, the vertical section with a length of 3 cm protruding from the baffle is used to fit the mold.

[0029] An exhaust pipe 4 is arranged between the baffle plate 9 and the position where the punch enters the metal pipe. The exhaust pipe 4 is divided into two sections, the first section is perpendicular to the cone surface 2 of the punch, an...

Embodiment 2

[0030] Embodiment two: combine figure 1 and Figure 4 Description It is suitable for local bulging of metal pipes. The cone surface 2 of the punch is determined according to the diameter of the metal pipe. The length of the punch entering the metal pipe 10 is 1 / 3 of the cone surface. The plate 9 is divided into three sections, the first section is perpendicular to the baffle plate at 2 / 3 of the cone surface, the second section is parallel to the metal pipe with a length of 50mm, and the third section is perpendicular to and in contact with the metal pipe , together form the air chamber 3, and guide the discharged high-temperature and high-pressure gas into the exhaust pipe 4. Such setting increases the application range of the punch for hot air forming of metal pipe fittings.

Embodiment 3

[0031] Example 3: The two-component sound-absorbing cotton 6 of this embodiment is polyester sound-absorbing cotton, and the sound-absorbing cotton 6 and the inner wall of the sound-absorbing chamber are connected by rivets. With such a setting, it has good material stability, will not expand and shrink due to temperature changes, is convenient for maintenance, and has a good noise reduction effect. Others are the same as those in Embodiment 1 or 2.

[0032] Working process: 1: Gas collection: When the sealing punch cone surface 2 enters the 1 / 3 position of the metal pipe, the extended section of the baffle plate 9 and the mold 11 form an air chamber. In the case of exhaust, the high-temperature and high-pressure gas is discharged from the matching gap between the metal pipe and the sealing cone surface, enters the air chamber 3, and then enters the exhaust pipe 4.

[0033] 2. Muffling and exporting gas: high-temperature and high-pressure gas enters the muffler chamber 5 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com