Box wall structure of logistics circulation box

A turnover box and box wall technology, which is applied in the field of box wall structure of logistics turnover box, can solve the problems of increasing the manufacturing cost of the box wall, increasing the types of parts and equipment, and increasing the cost of equipment, and achieves low mold opening cost, low production cost, The effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is a specific embodiment of the present invention combined with the accompanying drawings to further describe the technical solution of the present invention, but the present invention is not limited to this embodiment.

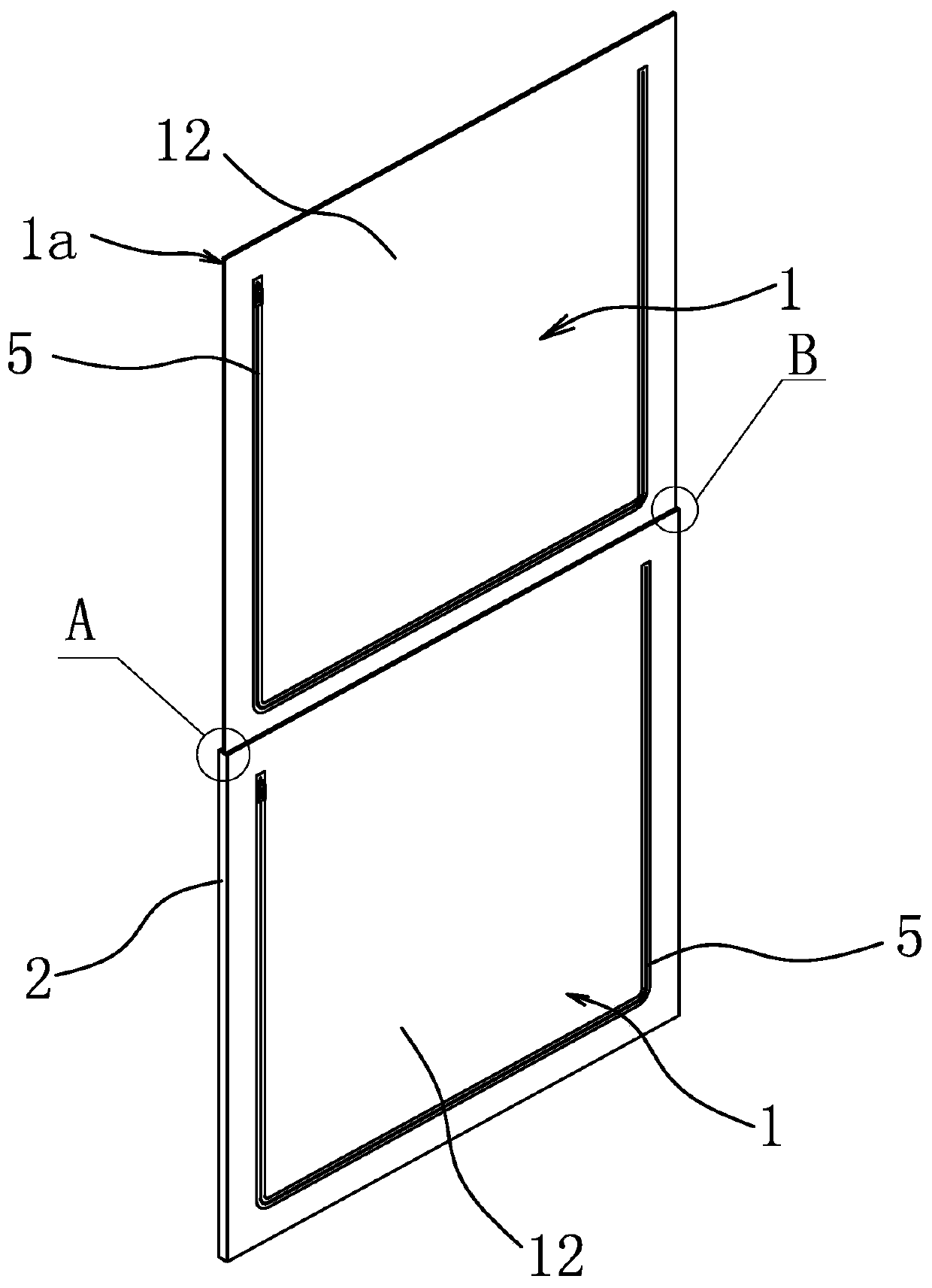

[0034] Such as figure 1 , figure 2 with image 3 As shown, the box wall structure of this logistics turnover box includes two parallel box plates 1, two strip-shaped plug-in boards 2, two plug-in boards 2 arranged oppositely and parallel to each other, two box boards 1 is arranged between two plug-in boards 2, and the plug-in boards 2 are formed by extrusion.

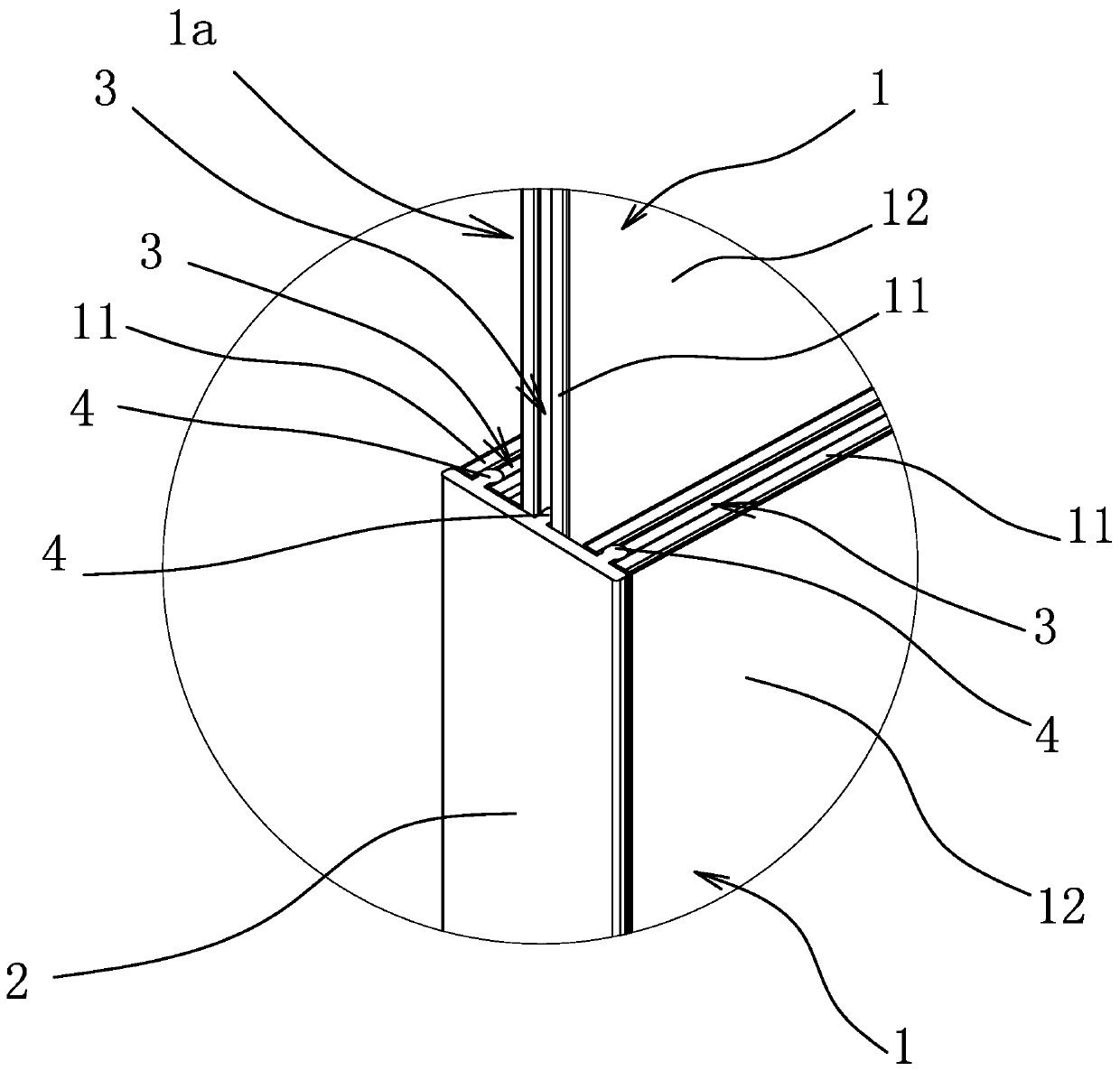

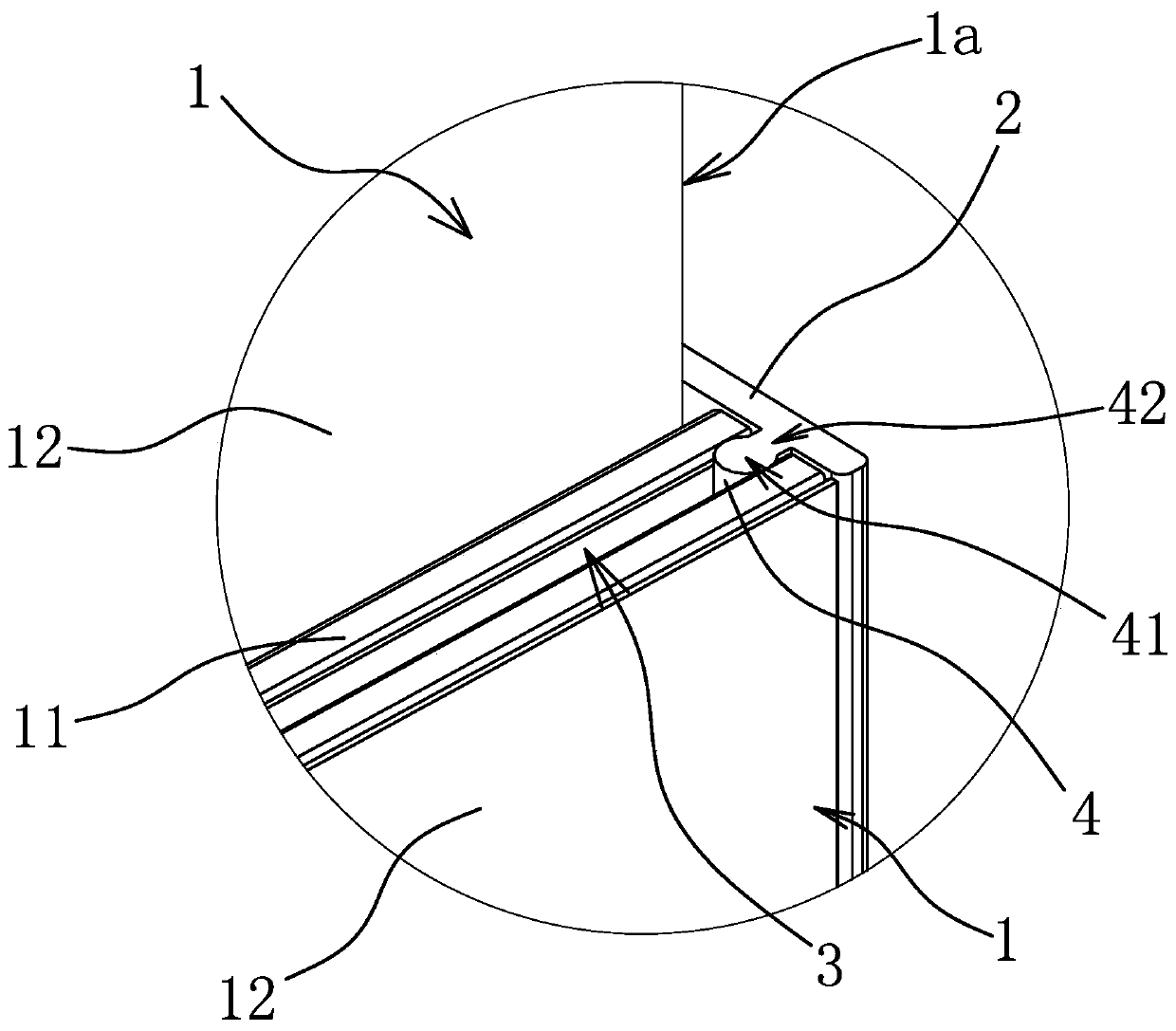

[0035] Such as Figure 4 , Figure 5 with Image 6 As shown, insertion grooves 3 are respectively provided on the left and right sides of the box plate 1, and the insertion grooves 3 extend along the length of the corresponding side of the box plate 1, and each insertion plate 2 is provided with three insertion protrusions 4 And three plug-in protruding strips 4 are arranged at interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com