Double-valve inner-cavity driving core tube valve

A valve core tube, valve body technology, applied in the direction of lift valve, valve device, engine components, etc., to achieve the effect of small opening and closing resistance, high cost performance and less friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

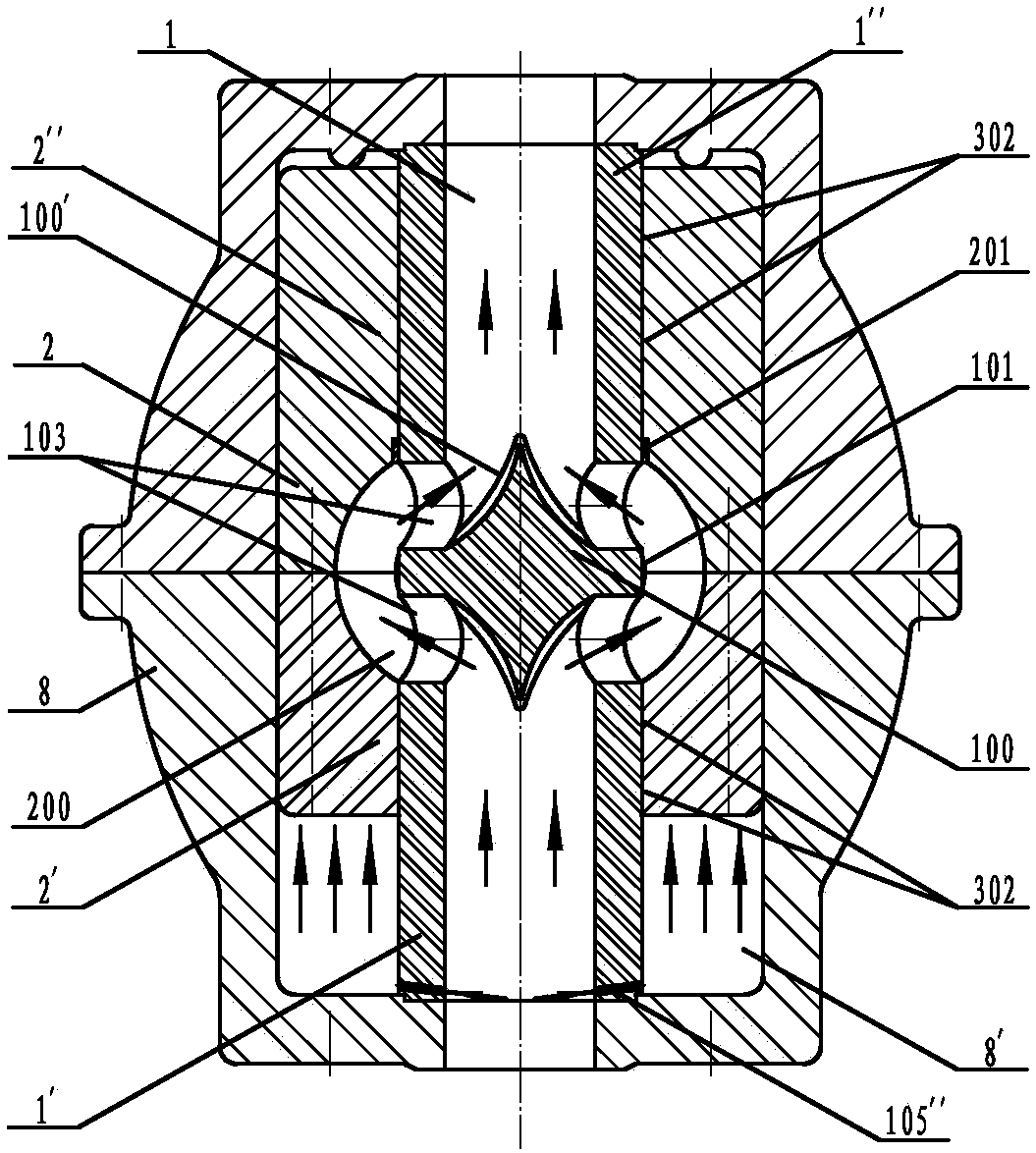

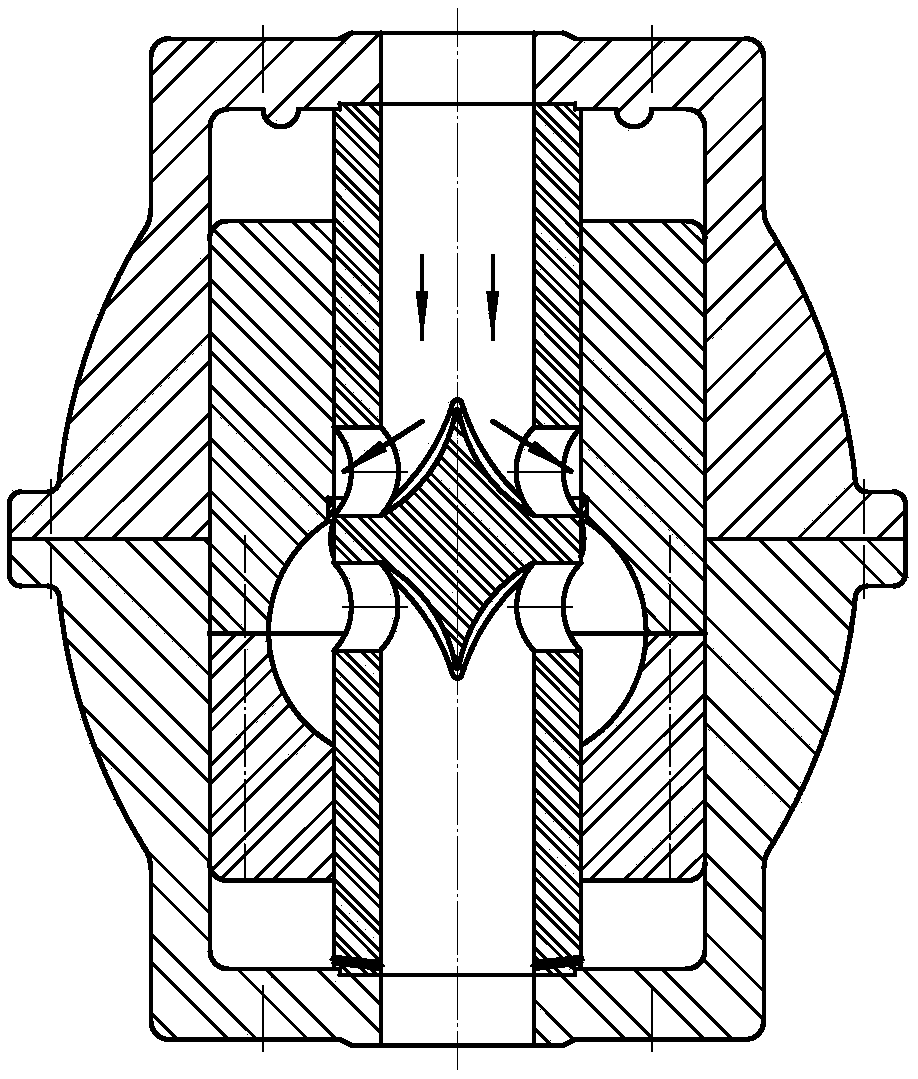

[0037] See attached figure 1 , 2 , the dual-valve inner chamber drive core tube valve described in this embodiment is used for pressure opening and closing and check; the valve core tube 1 wrapped in the inner cavity 8' of the outer valve body 8 is a fixed part perpendicular to the ground and coaxial From bottom to top, it runs through the sleeve pipe I2' of the valve body 2, the inner cavity 200 of the valve body 2, and the sleeve pipe II2" of the valve body 2; both the input section 1' and the output section 1" have two radial flow holes 103; The two axial end faces of the inner core of the layer 100 are tongue-shaped triangular slope surfaces 100'; the sealing surface of the annular valve core 101 is a circular arc slope surface and the annular valve seat 201 of the sleeve pipe II2 "throat constitutes a sealing pair; the input section 1' and Sleeve I2' and the junction of output section 1" and sleeve II2" are provided with sealing ring 302; the lower inner cavity 8' of out...

Embodiment 2

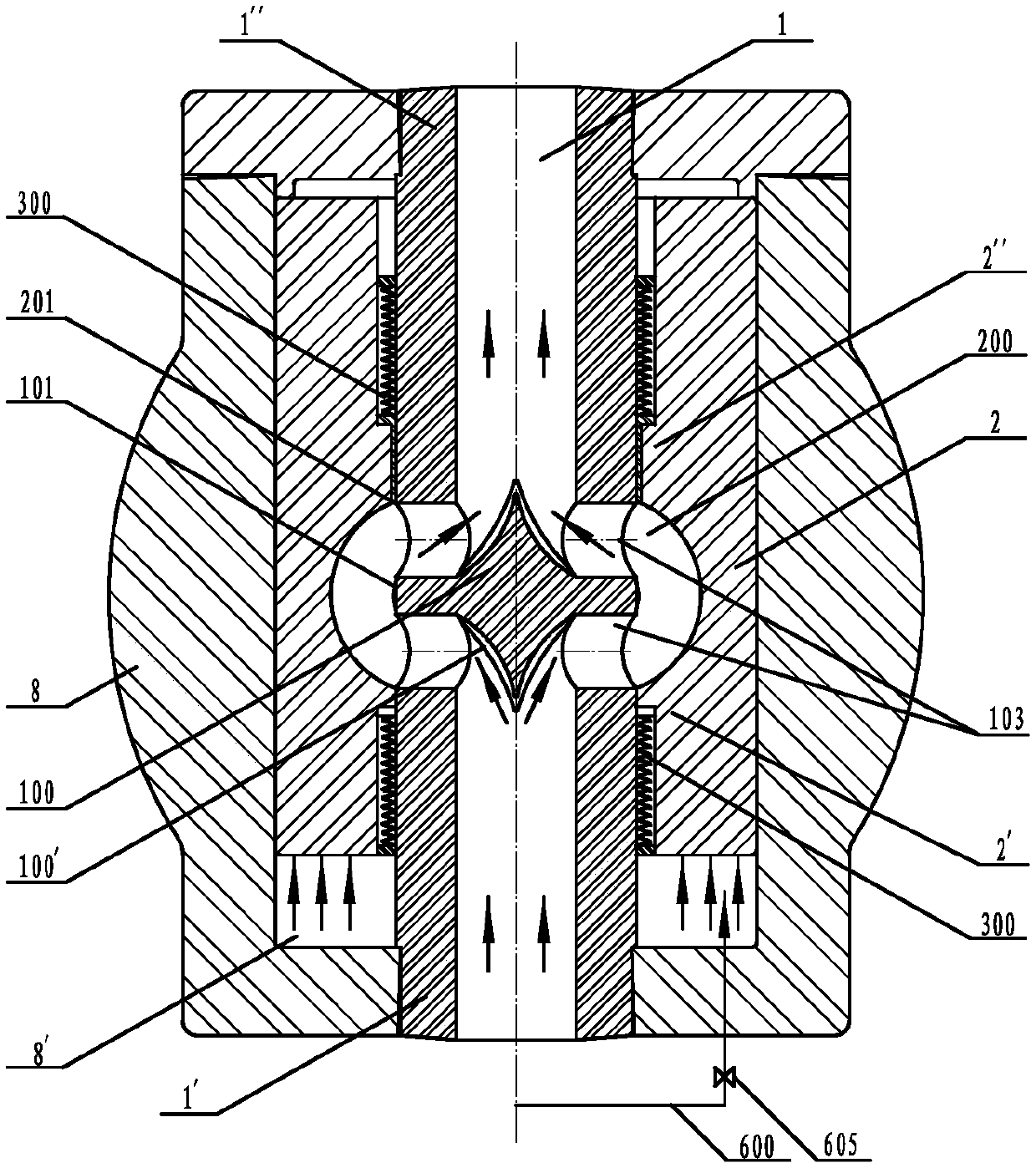

[0041] See attached image 3 , 4, the dual-valve internal cavity drive core tube valve described in this embodiment is normally open, used for opening and closing, and non-return; the valve core tube 1 wrapped in the inner cavity 8' of the outer valve body 8 is a fixed part perpendicular to the The ground coaxially runs through the sleeve pipe I2' of the valve body 2, the inner cavity 200 of the valve body 2, and the sleeve pipe II2" of the valve body 2 from bottom to top; both the input section 1' and the output section 1" have two radial flow holes 103; the two axial end faces of the inner core of the interlayer 100 are tongue-shaped triangular slope surfaces 100′; the sealing surface of the annular valve core 101 is a bidirectional slope surface and the annular valve seat 201 at the throat of the sleeve pipe II 2″ constitutes a sealing pair; the input section 1 Bellows seals 300 are provided at the joints between ' and sleeve I2' and output section 1" and sleeve II2", and ...

Embodiment 3

[0045] See attached Figure 5 , 6 , the dual-valve inner cavity driving core tube valve described in this embodiment is used for opening and closing and check; the valve core tube 1 wrapped in the inner cavity 8' of the outer valve body 8 is a fixed part perpendicular to the ground and coaxial From bottom to top, it runs through the sleeve tube I2' of the valve body 2, the inner cavity 200 of the valve body 2, and the sleeve tube II2" of the valve body 2; both the input section 1' and the output section 1" have two radial flow holes 103; the interlayer The two axial end faces of the inner core of 100 are tongue-shaped triangular slope surfaces 100′; the sealing surface of the annular valve core 101 surrounding and embedded in the interlayer 100 is a two-way slope surface and the annular valve seat 201 at the throat of the sleeve pipe II 2″ constitutes a sealing pair; Bellows seals 300 are provided at the joints of the input section 1' and the sleeve tube I2' and the output se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com