Impact-resistance vacuum interface valve

An impact-resistant and vacuum technology, applied in valve details, diaphragm valves, valve devices, etc., can solve the problems of fatigue damage of piston diaphragm, impact of piston diaphragm, corresponding speed, tightness and reliability are not ideal, etc. The effect of prolonging service life and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

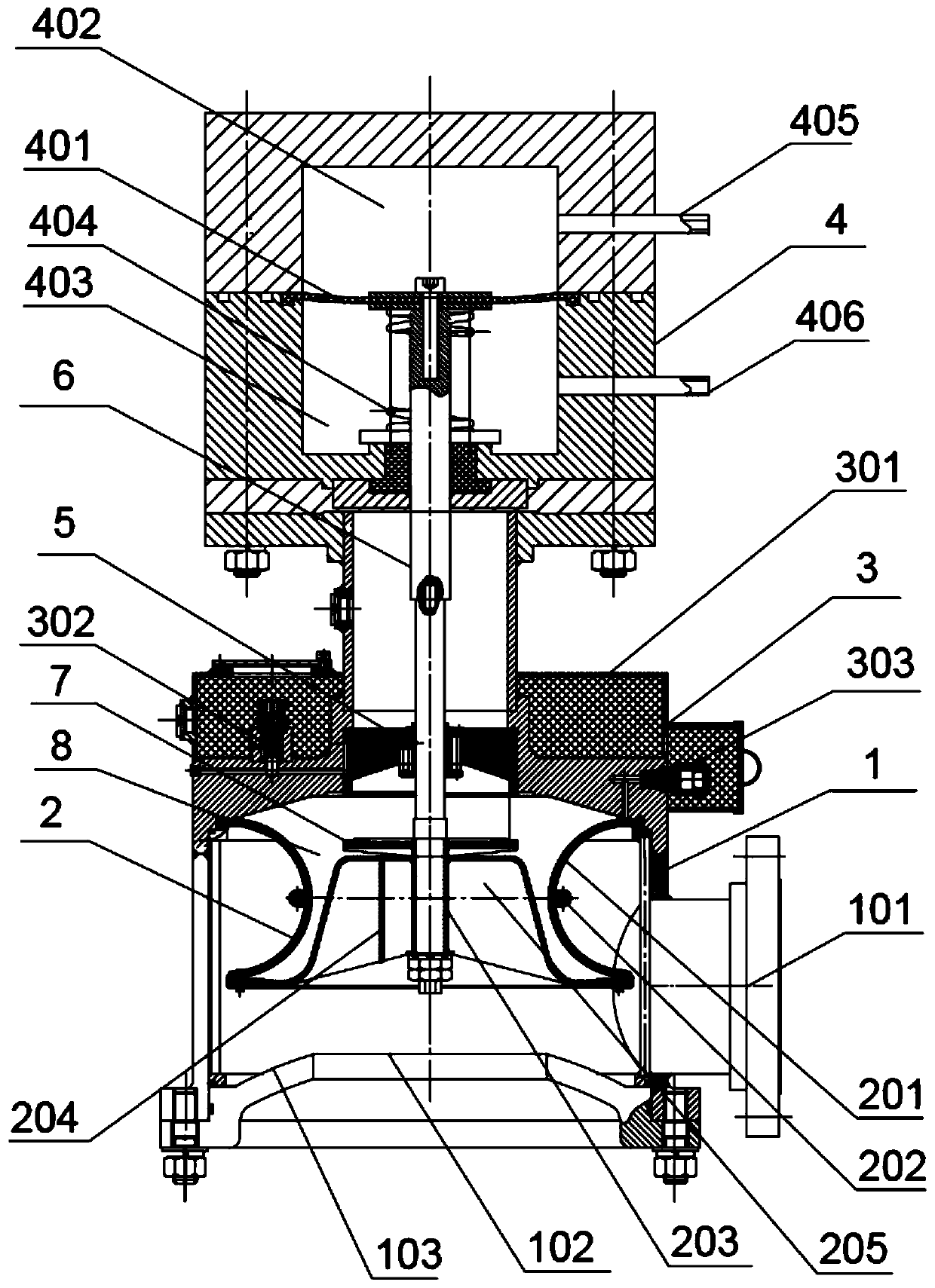

[0018] refer to figure 1 , a shock-resistant vacuum interface valve of the present invention, comprising a valve body 1 and a piston diaphragm 2 located in the valve body, the valve body is provided with a first outlet 101 and a first inlet 102, characterized in that: the piston diaphragm The opening at the upper end is in sealing connection with the top wall of the valve body, forming an airtight damping chamber 8; the vacuum interface valve also includes a damping system 3 and a vacuum drive system 4; the damping system includes a damping fluid for The damping fluid chamber 301 storing the damping fluid and the first one-way valve 302 and the second one-way valve 303 used to control the flow direction of the damping fluid; the vacuum driving system is provided with a driving diaphragm 401, and the driving diaphragm and the piston The diaphragm is fixedly connected through the connecting rod 6; the damping chamber is filled with the damping liquid, and when the piston diaphra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com