Polyurethane sample quality inspection method, electronic nose equipment and storage medium

A quality inspection, polyurethane technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the impossible to arrange smell test, different problems, achieve high accuracy and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

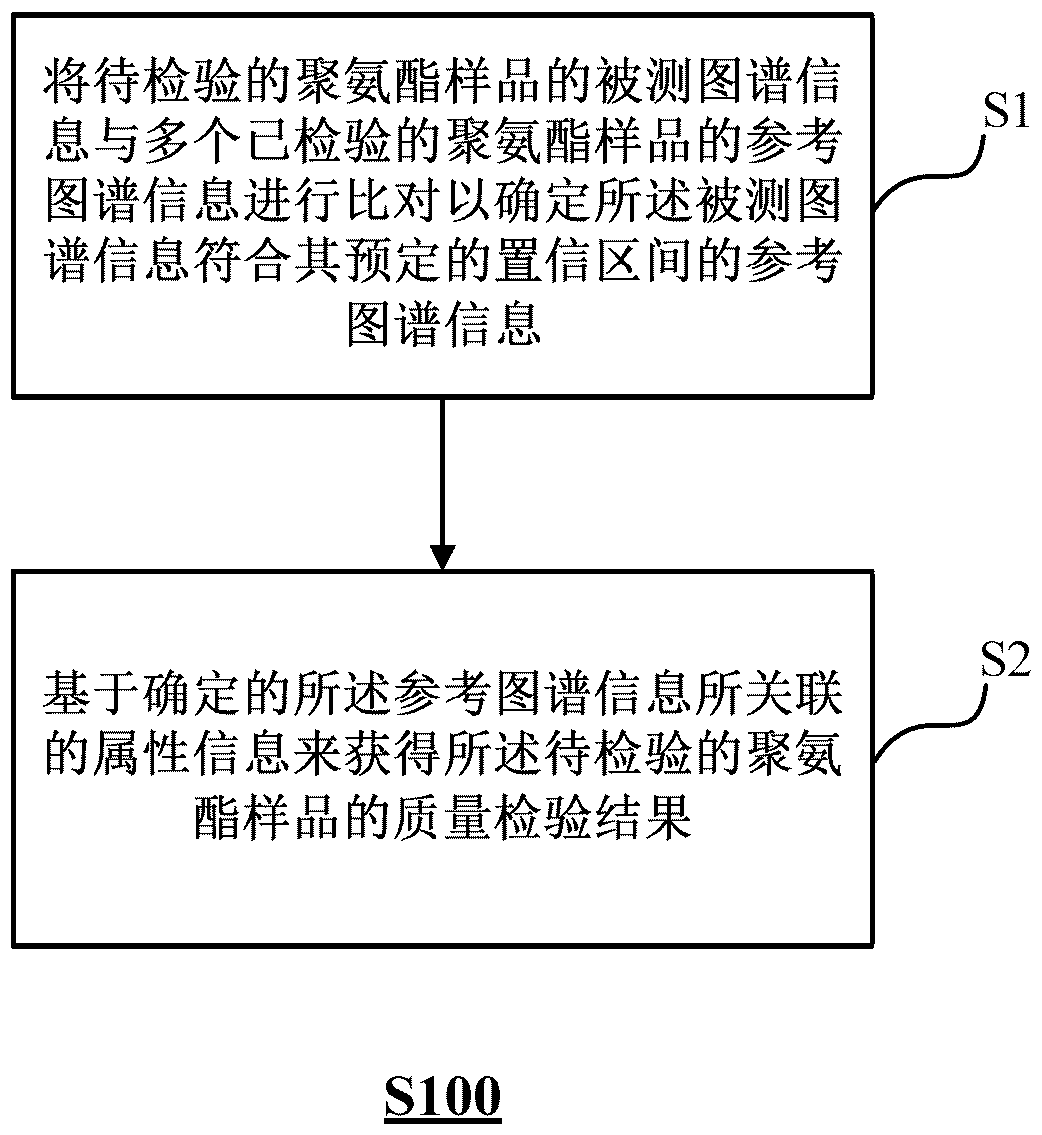

Method used

Image

Examples

Embodiment Construction

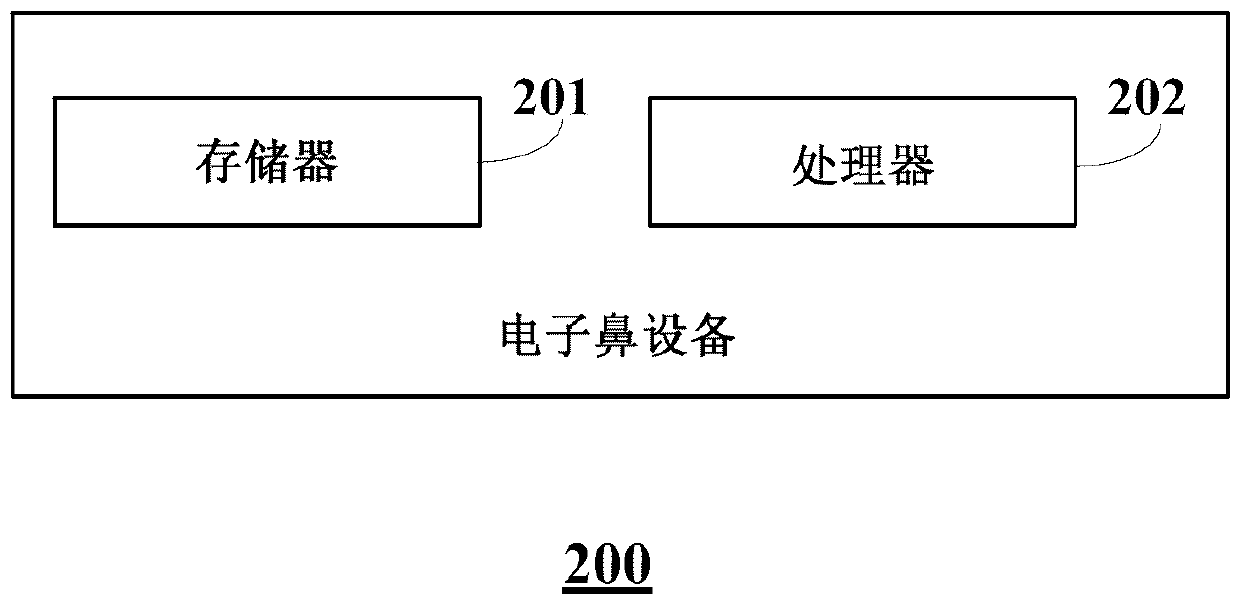

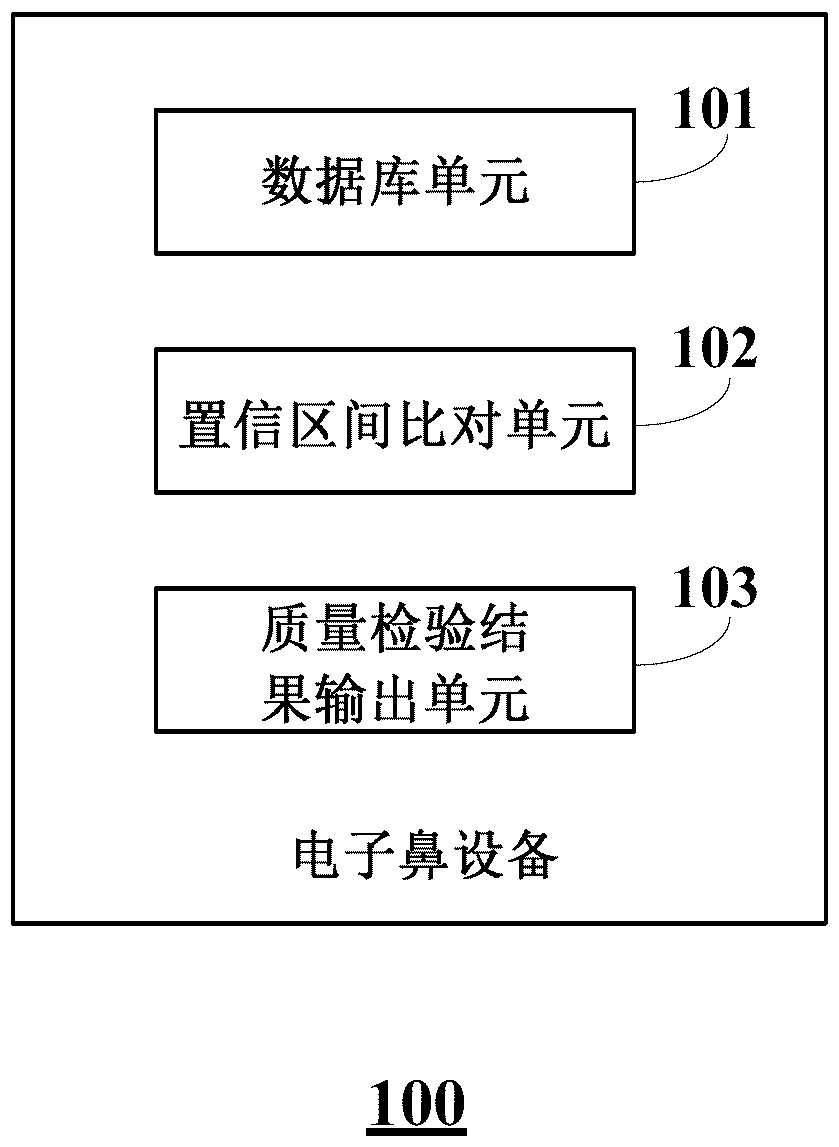

[0032] Hereinafter, the quality inspection method, electronic nose device, and storage medium of the polyurethane sample involved in the present invention will be described in further detail with reference to the accompanying drawings. It should be noted that the following specific implementations are exemplary rather than limiting, and are intended to provide a basic understanding of the present invention, and are not intended to confirm the key or decisive elements of the present invention or limit the scope of protection.

[0033] Hereinafter, the present invention will be described with reference to block diagrams, block diagrams and / or flowcharts of methods and devices in the embodiments of the present invention. It will be understood that each block of these flowchart illustrations and / or block diagrams, and combinations of flowchart illustrations and / or block diagrams, can be implemented by computer program instructions. These computer program instructions can be provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com