Welding method of pipe head of heat exchange equipment

A welding method and tube head technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of welding bubbles and incomplete penetration in the welding seam, achieve the refinement of the welding seam, improve the pull-off strength, and improve the welding The effect of seam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

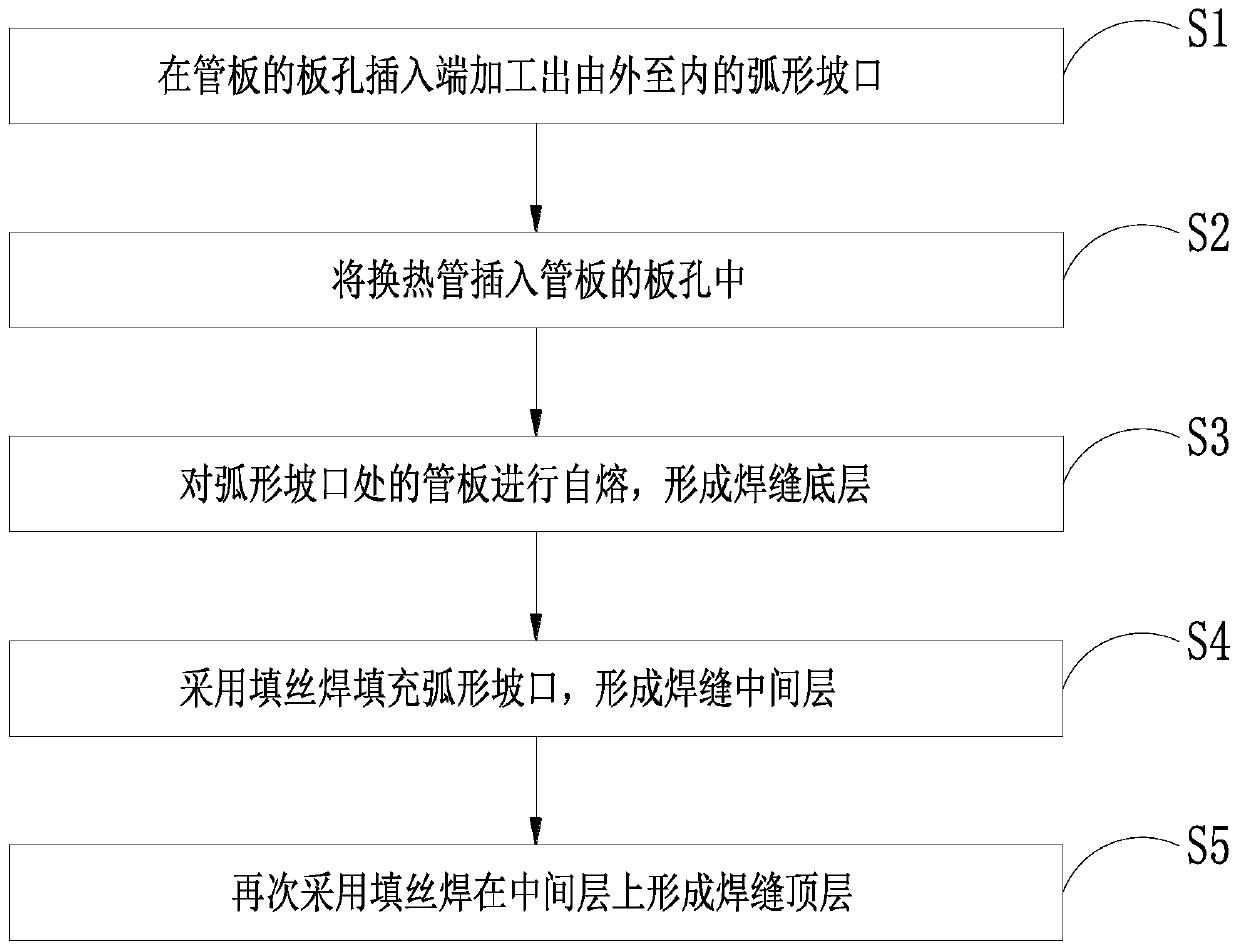

[0024] Such as figure 1 , image 3 and Figure 4 As shown, a method for welding a pipe head of a cold exchange equipment includes the following steps:

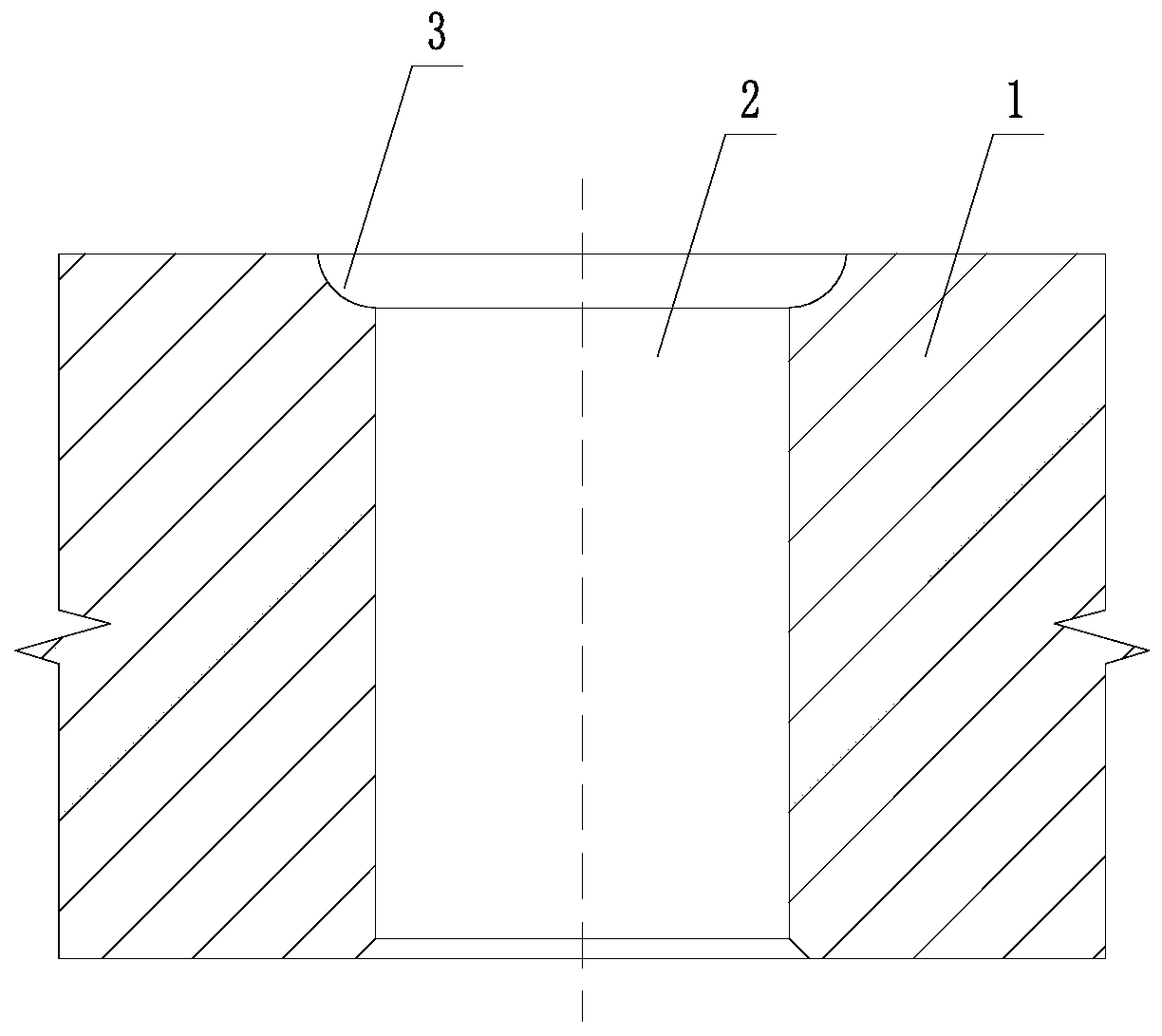

[0025] S1. Process an arc-shaped groove 3 from outside to inside at the insertion end of the plate hole 2 of the tube sheet 1. Specifically, the insertion end of the plate hole 2 is the outside of the tube plate 1 after it is installed in the cooling equipment.

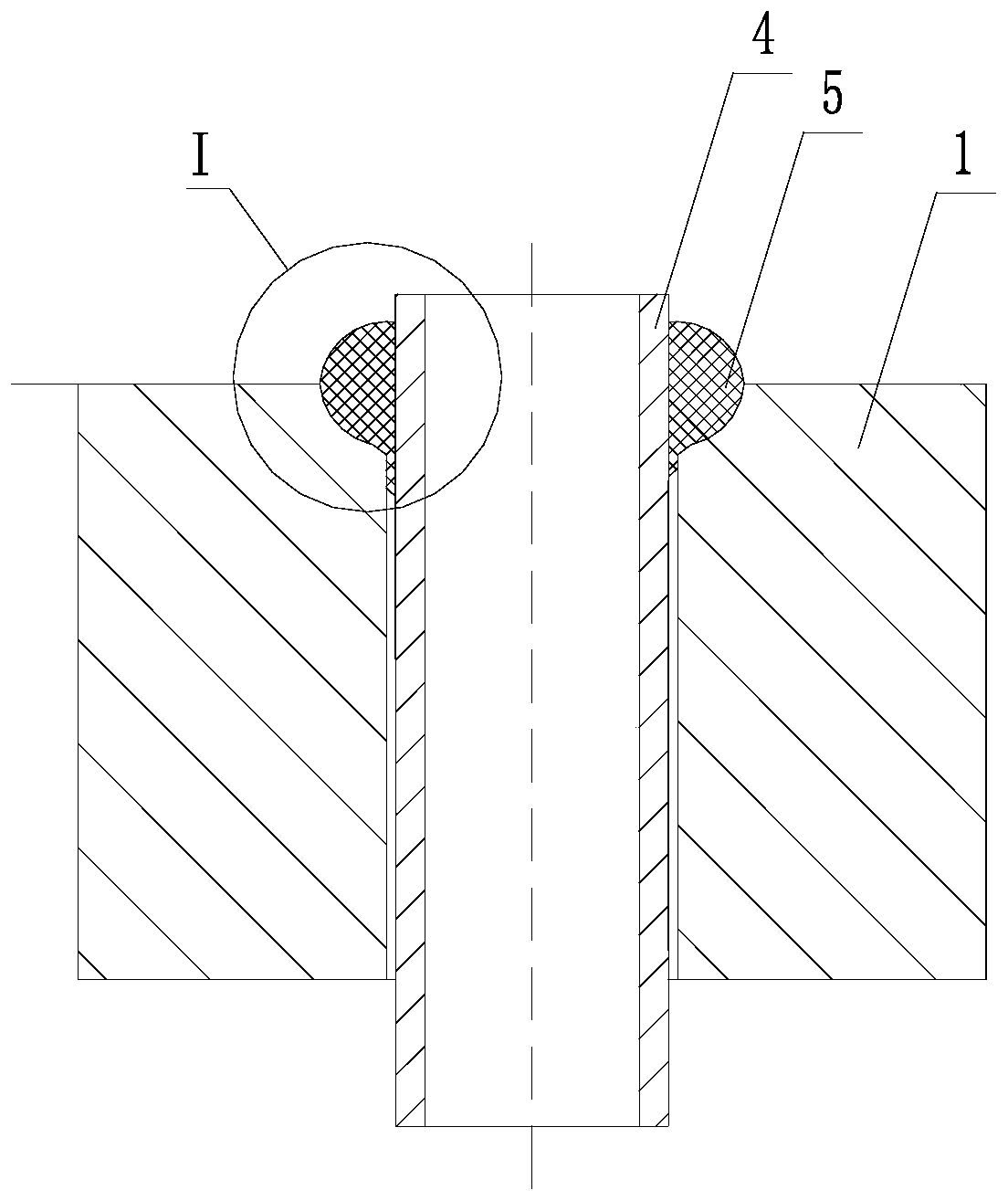

[0026] S2. Insert the heat exchange tube 4 into the plate hole 2 from the insertion end, and the tube head of the heat exchange tube 4 protrudes from the arc groove 3 . Specifically, the insertion end of the heat exchange tube 4 is any end to be welded with the tube sheet 1 . Preferably, the tube heads of the heat exchange tubes 4 protrude from the arc-shaped groove 3 of the tube sheet 1 by 4-5 mm.

[0027] S3. Carry out self-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com