D-type joined V-belt

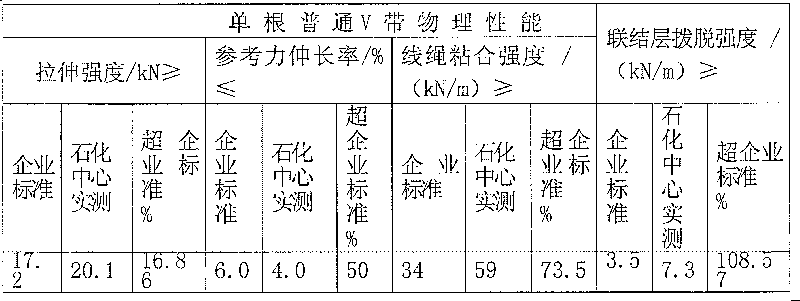

A D-shaped, connecting layer technology, applied in the direction of V-shaped belts, belts/chains/gears, mechanical equipment, etc., can solve problems such as uneven force, reduced service life of V-belts, and difficulty in using and matching, so as to improve the tensile strength. Tensile strength and cord bonding strength, improved load capacity and service life, and improved lateral stiffness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

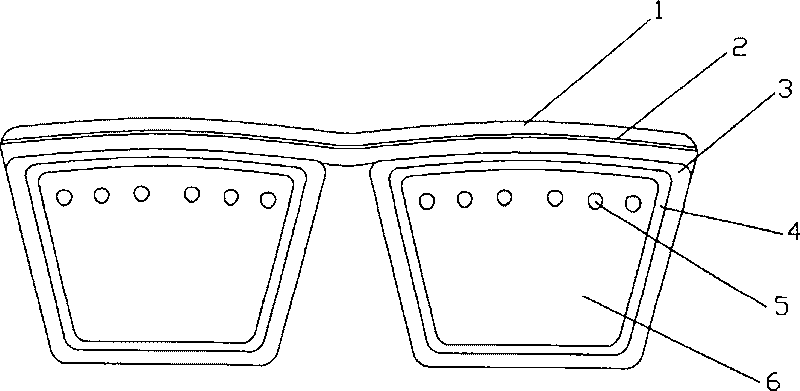

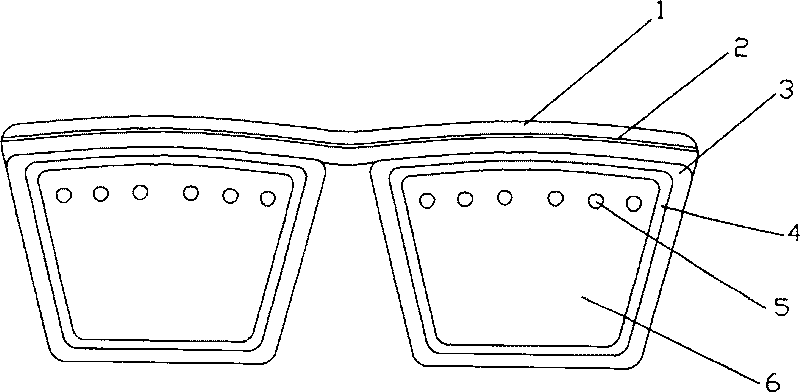

[0026] The embodiment of the present invention is a combined V-belt formed by connecting two single V-belts. Glue 6, buffer glue 4, dipped polyester cord 5, wrapping layer 3, the wrapping layer 3 is set on the outermost layer of a single V-belt, and the bottom glue 6 is set on the core of a single V-belt. The dipped polyester cord 5 adopts a 12×3 cord, and the cord is buried between the buffer rubber 4 , and the buffer rubber 4 is arranged between the cord 5 and the covering layer 3 .

[0027] Among them, the raw material formula of primer 6 is: 80 parts of smoked sheet rubber, 20 parts of styrene-butadiene rubber, 50 parts of carbon black, 2.5 parts of accelerator, 2.2 parts of sulfur, 4 parts of pine tar, 3 parts of anti-aging agent, 80 parts of reinforcement agent and 10 parts of softening agent; the raw material formula of described buffer rubber 4 is: 100 parts of smoked sheet rubber, 30 parts of carbon black, 2.2 parts of accelerator, 2 parts of sulfur, 4 parts of pine t...

Embodiment 2

[0053] The embodiment of the present invention is a combined V-belt formed by connecting two single V-belts. Glue 6, buffer glue 4, dipped polyester cord 5, wrapping layer 3, the wrapping layer 3 is set on the outermost layer of a single V-belt, and the bottom glue 6 is set on the core of a single V-belt. The dipped polyester cord 5 adopts a 12×3 cord, and the cord is buried between the buffer rubber 4 , and the buffer rubber 4 is arranged between the cord 5 and the covering layer 3 .

[0054] Among them, the raw material formula of primer 6 is: 80 parts of smoked sheet rubber, 20 parts of styrene-butadiene rubber, 50 parts of carbon black, 2.5 parts of accelerator, 2.2 parts of sulfur, 4 parts of pine tar, 3 parts of anti-aging agent, 80 parts of reinforcement agent and 10 parts of softening agent; the raw material formula of described buffer rubber 4 is: 100 parts of smoked sheet rubber, 30 parts of carbon black, 2.2 parts of accelerator, 2 parts of sulfur, 4 parts of pine t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com