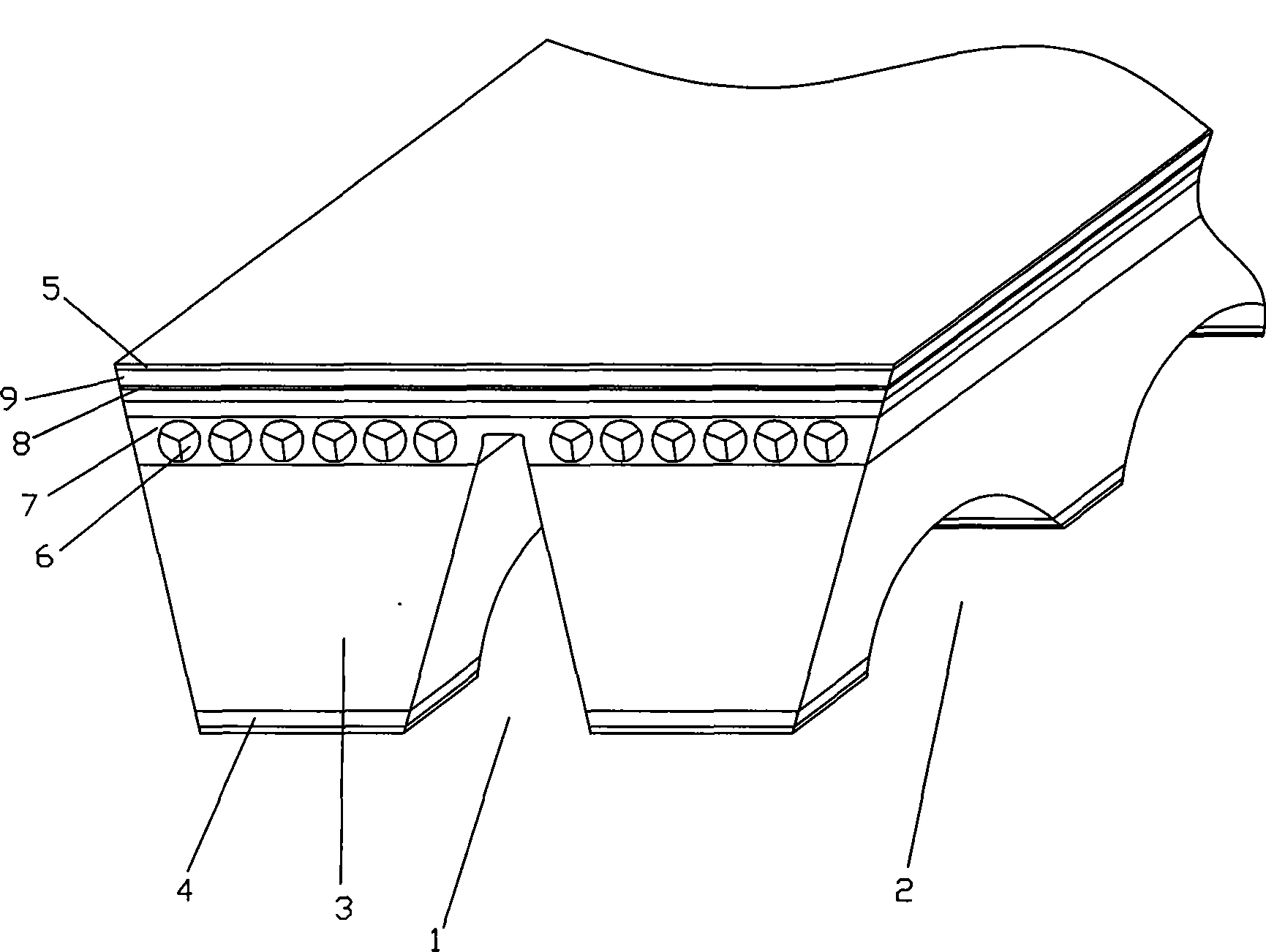

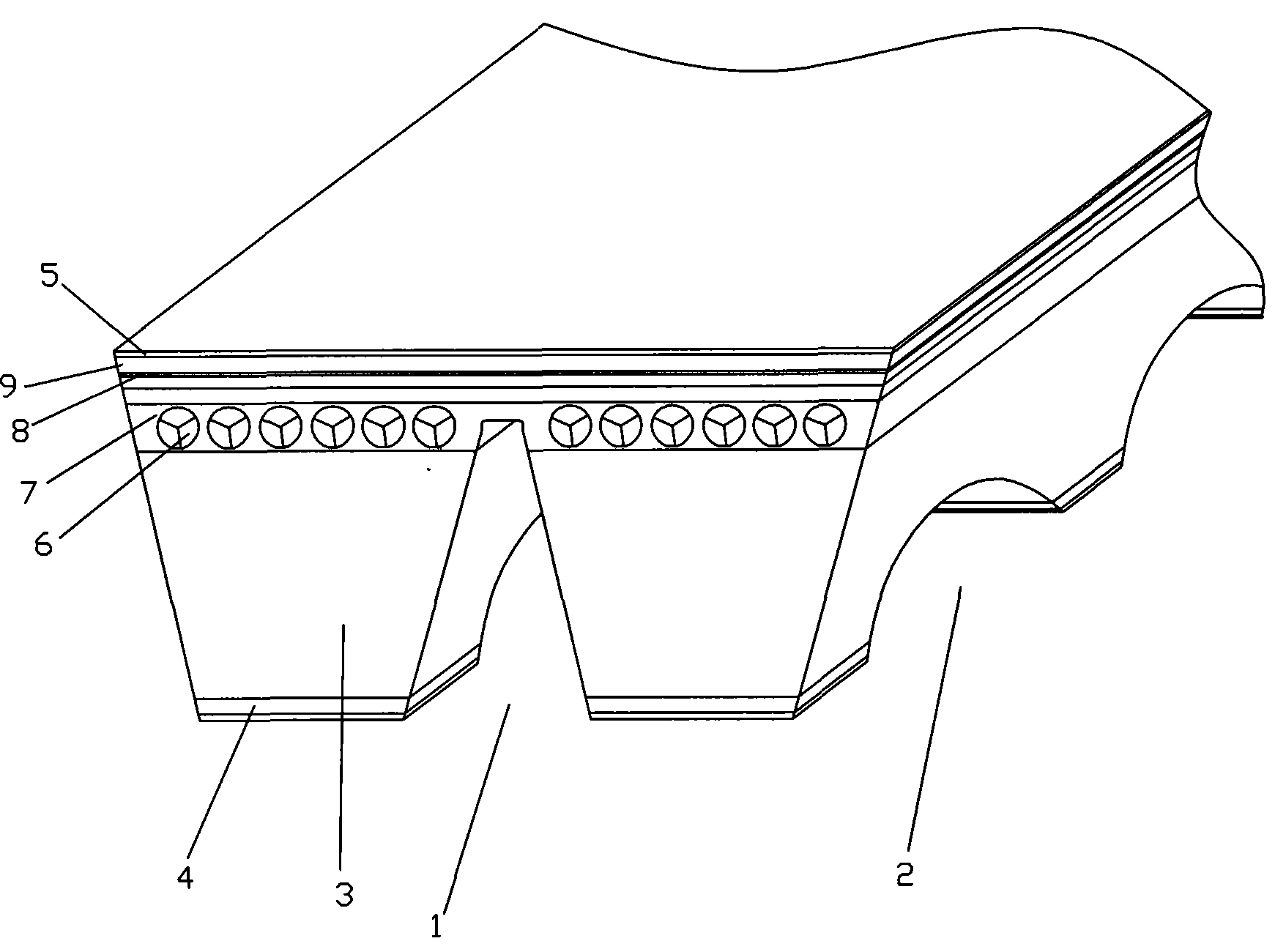

Two-sided transmission unit belt

A combined belt, double-sided technology, applied in the direction of V-belt, belt/chain/gear, mechanical equipment, etc., can solve the problems of low life of the combined belt and low performance index of the combined belt, so as to improve the bearing capacity and Service life, optimal process and process parameters, effect of improving load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

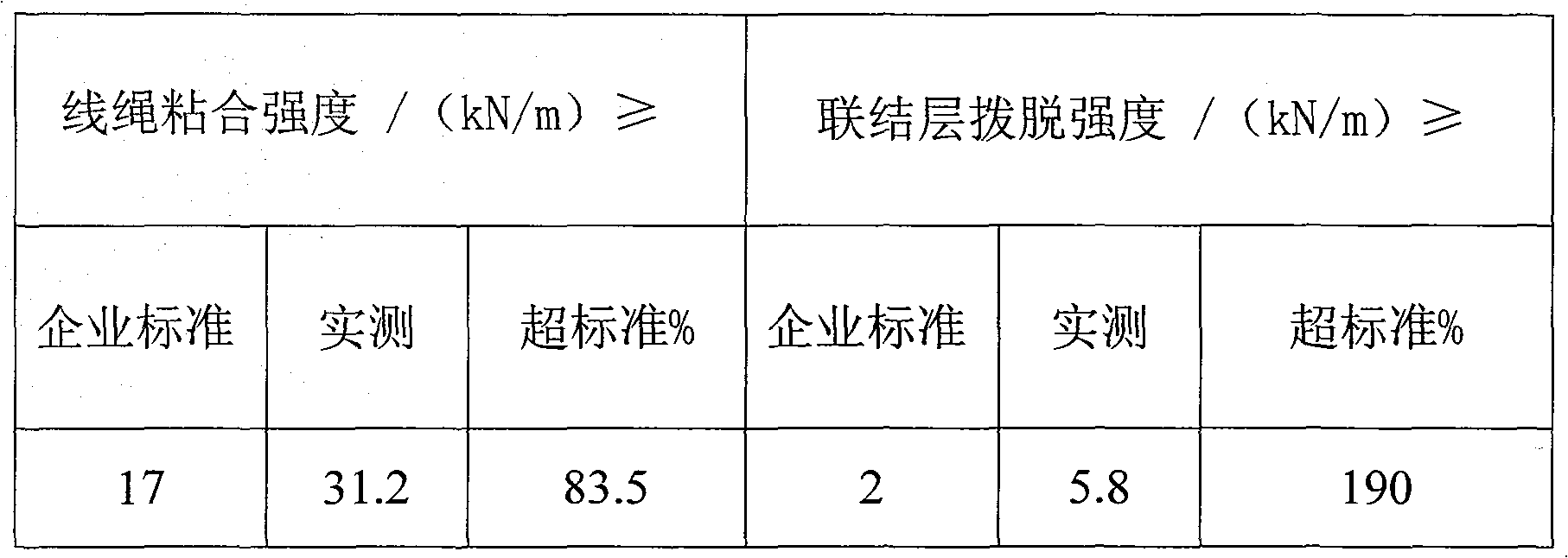

Examples

Embodiment 1

[0023] 20 parts of nylon short fiber and 4 parts of pine oil; the formula of the ingredients of the buffer glue is: 100 choprylite, zinc oxide, 5.5 part of magnesium oxide, 2 parts of hard ester acid, 55 parts of charcoal black, 2 part of the agent anti -agent agent, 2 parts of anti -veteran agent agent, 4 parts of pine caramel, 5 parts of adhesives; the formula of the raw material of the cloth layer is: 100 parts of chlorite, 5 parts of zinc oxide, 4 parts of magnesium oxide, 2 parts of hard esters, 40 parts of charcoal black, 2 parts of anti -old -fashioned old -fashioned old -fashioned old -fashioned old -fashioned old -fashioned old -fashionedDose, 4 loose caramel, 5 parts of adhesive; the raw material formula of the curtain cloth glue is: 100 cigarettes, 2.1 promotional agents, 3 parts of anti -agent, 6 softeners, 30 charcoal black, 50 supplementsStrong agent, 4 loose caramel, sulfur and 8 parts of adhesive.In the ingredients of the above-mentioned rubber, the smoke tapery in...

Embodiment 2

[0039] 20 parts of nylon short fiber and 4 parts of pine oil; the formula of the ingredients of the buffer glue is: 100 choprylite, zinc oxide, 5.5 part of magnesium oxide, 2 parts of hard ester acid, 55 parts of charcoal black, 2 part of the agent anti -agent agent, 2 parts of anti -veteran agent agent, 4 parts of pine caramel, 5 parts of adhesives; the formula of the raw material of the cloth layer is: 100 parts of chlorite, 5 parts of zinc oxide, 4 parts of magnesium oxide, 2 parts of hard esters, 40 parts of charcoal black, 2 parts of anti -old -fashioned old -fashioned old -fashioned old -fashioned old -fashioned old -fashioned old -fashionedDose, 4 loose caramel, 5 parts of adhesive; the raw material formula of the curtain cloth glue is: 100 cigarettes, 2.1 promotional agents, 3 parts of anti -agent, 6 softeners, 30 charcoal black, 50 supplementsStrong agent, 4 loose caramel, sulfur and 8 parts of adhesive.In the ingredients of the above-mentioned glue, the smoke tape in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com